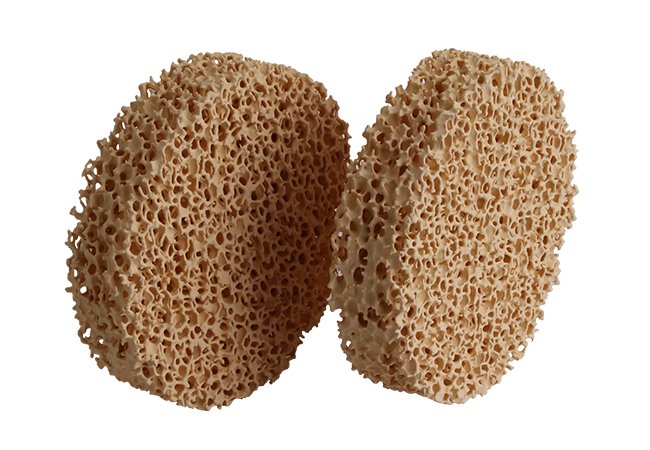

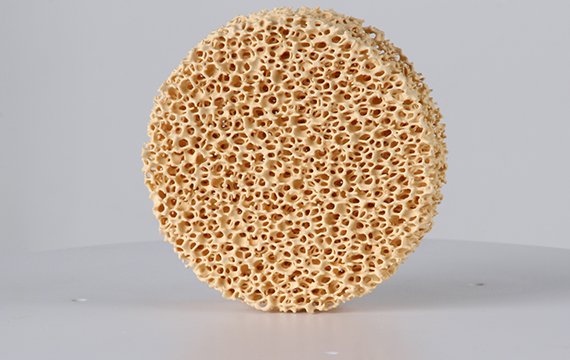

Zirconia Ceramic Foam Filters

SEFU Zirconia ceramic foam filters have been specially developed for filtering small steel casings with high pouring temperatures and improving the purity of metal liquid.

- Remarkable filtering effect on all steel grades.

- Made of pure zirconia material, the temperature can reach 1760°C.

- Excellent raw materials and advanced production technology.

- Stable dimensional tolerance.

Custom Service and Technical Support

SEFU organizes high-quality zirconia ceramic foam filters.

SEFU CERAMIC provides a series of zirconia ceramic filter products with various specifications according to your needs. SEFU professional engineers are at your service, and you will receive comprehensive technical support. Our company provides you with the design, manufacture, installation, and use guidance of pouring filter systems.

- Product Parameters

- Regular Sizes and Filtration Capacity

| Chemical Composition | ZrO2/SIO2 |

| Porosity (%) | 80~90% |

| Colour | Yellow |

| Application Temperature | Max.1700°C |

| Compression Strength (Mpa) | ≥1.2 |

| Thermal Shock Resistance | 1100°C—room temperature 6 times |

| Bulk Density | 0.8-0.9g/cm3 |

| Size (mm) |

Flow Rate (kg/s) |

Capacity (kg) |

|

| Carbon Steel | Alloyed Steel | ||

| 40×40×20 | 2 | 2.5 | 32 |

| 50×50×22 | 3 | 4 | 50 |

| 55×55×22 | 4 | 5 | 55 |

| 60×60×22 | 3 | 4 | 70 |

| 60×60×25 | 3 | 4 | 70 |

| 75×75×25 | 5 | 6.5 | 105 |

| 100×100×25 | 7 | 10 | 190 |

| 150×150×30 | 17 | 22 | 420 |

| Dia 50×22 | 2 | 3 | 40 |

| Dia 50×25 | 1.5 | 2.5 | 40 |

| Dia 60×25 | 2 | 3.5 | 50 |

| Dia 70×25 | 3 | 4.2 | 70 |

| Dia 75×25 | 4 | 5.5 | 85 |

| Dia 90×25 | 6 | 8 | 115 |

| Dia 100×25 | 7 | 9 | 145 |

| Dia 120×25 | 11 | 14 | 210 |

| Dia 150×30 | 12.5 | 15 | 330 |

SEFU Zirconia Ceramic Foam Filters Functions

- Zirconia ceramic foam filter can filter non-metal slag inclusions and slags as small as micrometers, making the surface of steel casting smoother and reducing machining losses.

- Purification processes for the production of castings such as steel and superalloys.

- It curtails the reject rate, primes cost & improves labor productivity.

SEFU Zirconia Ceramic Foam Filter Application

SEFU Zirconia Ceramic Foam Filter is productive and filters the intense heat of steel.

It is available at high temperature of 1760 ℃. It has a significant filtering effect on all steel types. Including carbon steel, stainless steel, cobalt-based nickel-based superalloy, etc.

Advantages of Zirconia Ceramic Filter

- Zirconia filter helps in keeping the metal purity.

- It offers resistance to high temperatures while maintaining excellent erosion resistance.

- Reduce the inclusions of steel casting.

- Decrease internal re-oxidation defects.

- It is applied to purify the molten carbon steel, steel alloy, and stainless steel.

- Reduce the sub-surface defects after machining.

- Purify molten steel and enhance the yield of steel casting.

Related Products

Want to buy more casting materials to improve the quality of your castings? Click below for more molten metal filtration products and other foundry materials.

FAQ Guide About Zirconia Ceramic Foam Filters

If you want to know anything else about Zirconia Ceramic Foam Filters, please contact us to leave your questions, professional foundry solutions are waiting for you.

Zirconia Ceramic Foam Filter is a phosphate-free, high melting point, It is characterized by high porosity and mechanochemical stability and excellent resistance to thermal shock and corrosion from molten steel.

Zirconia ceramic foam filter is a porous material with high-temperature properties. It is steadfast for filtering steel and alloy steel temperature resistant up to 1700°C.

In the process of transportation & use of the filter plate, it must withstand the impact of a certain pressure from the outside, so the index of compressive strength is also introduced in the standard as one of the bases for measuring the quality of the filter plate.