Ceramic Pouring Cup

SEFU Ceramic Pouring Cups are superior quality ceramic casting molds used for pouring molten metal into Castings intended shapes.

- Protection against the heat and hazards of molten metal

- Retaining excellent accuracy in the casting

- Custom manufacturing to meet different requirements

- Technical Parameters

- Specifications

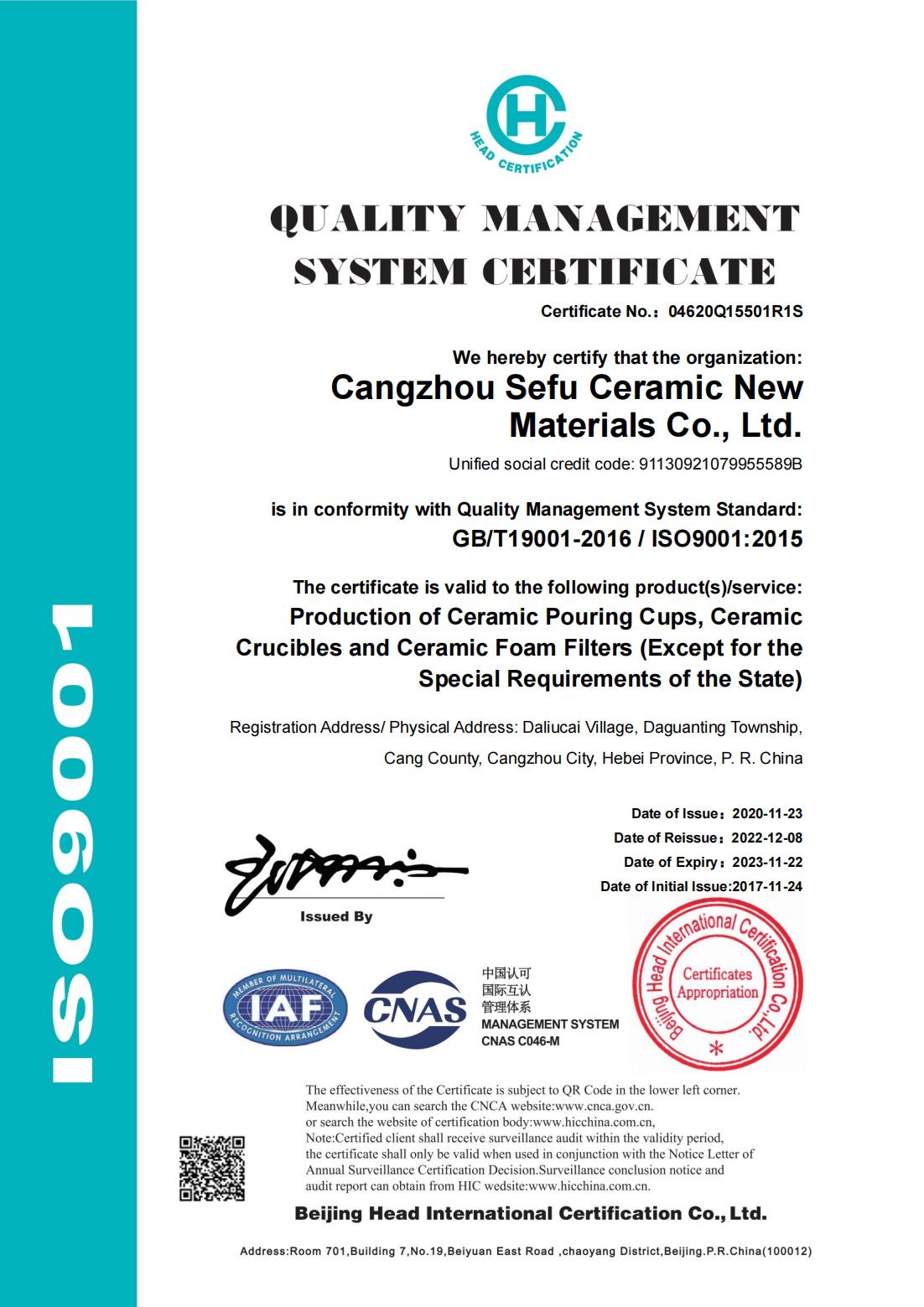

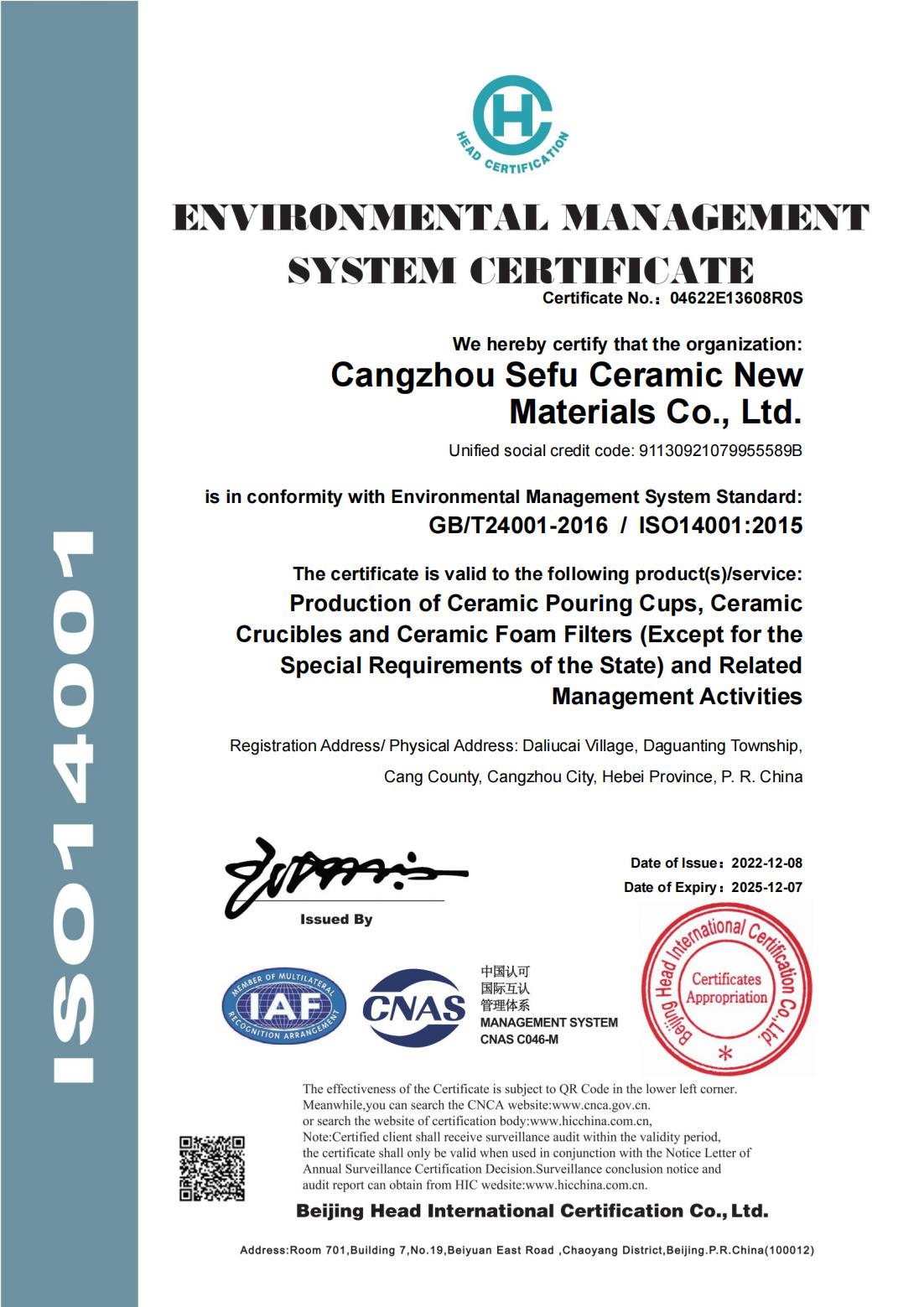

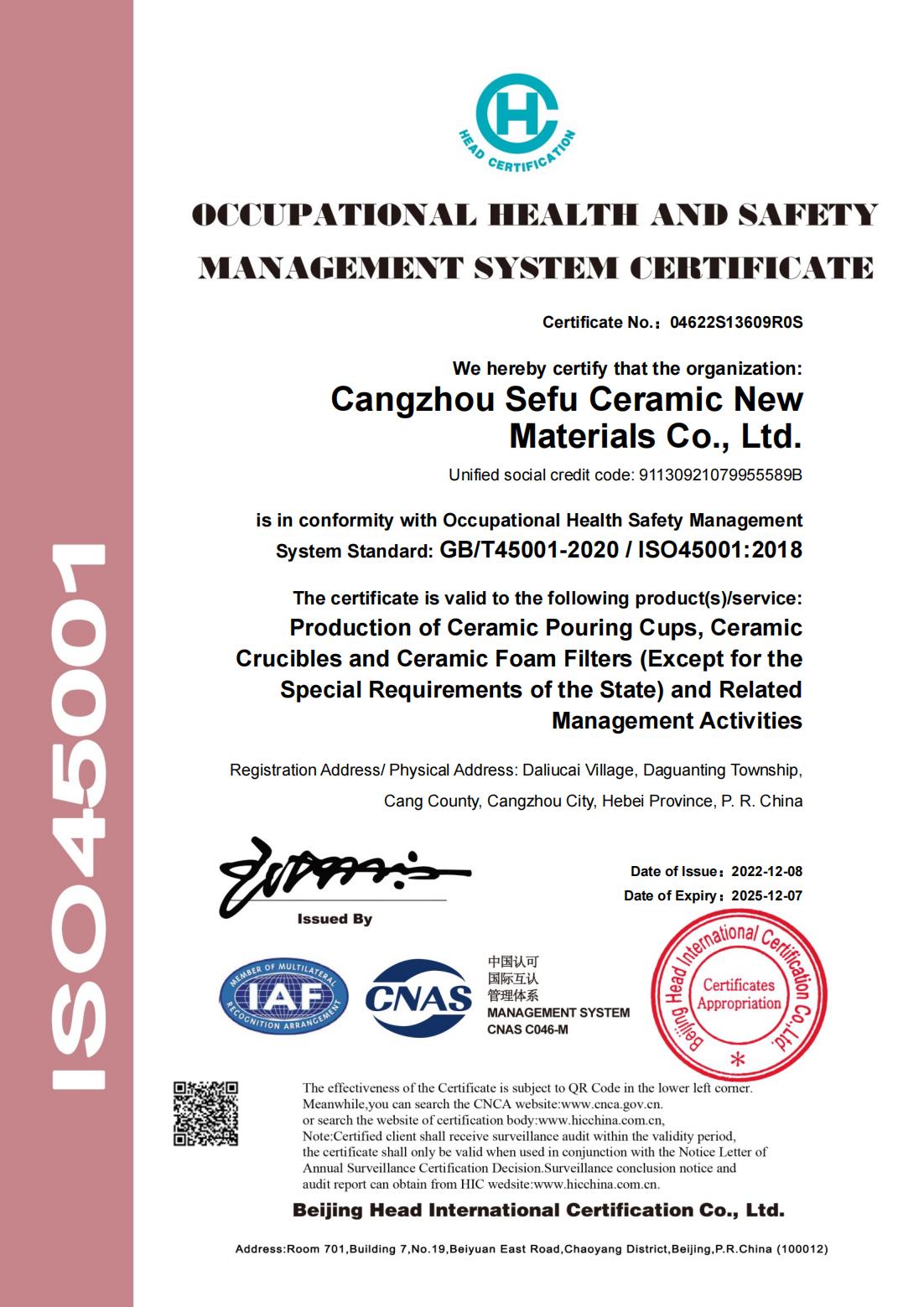

- Certificates

| Product Name | Ceramic Pouring Cups |

| Material | High Alumina Silicate |

| Operating Temperature (℃) | 1650 |

| Flexural Strength at Room Temperature (MPa) | > 10 |

| Coefficient of Thermal Expansion | 8~9×10-6 |

| Application | High Temperature Alloy, Stainless Steel |

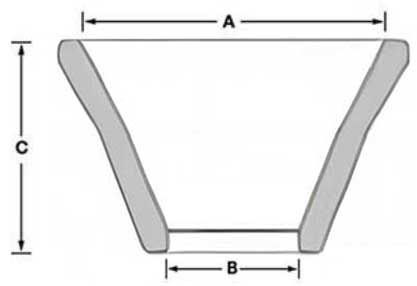

| Product Specifications | A mm(inch) | B mm(inch) | C mm(inch) |

| 0101 | 77(3.03) | 45(1.77) | 40(1.57) |

| 0102 | 90(3.54) | 60(2.36) | 50(1.97) |

| 0201 | 130(5.11) | 54(2.12) | 97(3.82) |

| 0202 | 200(7.87) | 92(3.62) | 205(8.07) |

| 0203 | 200(7.87) | 60(2.36) | 180(7.08) |

| 0204 | 170(6.69) | 92(3.62) | 140(5.51) |

| 0301 | 145(5.70) | 52(2.04) | 106(4.17) |

| 0302 | 145(5.70) | 52(2.04) | 106(4.17) |

| 0501 | 212.8(8.37) | 101.6(4) | 133.3(5.26) |

| 0502 | 138.4(5.45) | 76.2(3) | 107.9(4.24) |

| 0601 | 121(4.76) | 70(2.76) | 62(2.44) |

| 0701 | 124(4.88) | 53(2.08) | 84(3.30) |

| 0801 | 182(7.16) | 59.5(2.34) | 130(5.11) |

| 0901 | 124(4.88) | 61.5(2.42) | 88.5(3.48) |

| 1101 | 265(10.43) | 58(2.28) | 250(9.84) |

Products need to be customized according to your needs.

Customized Production

SEFU Investment Casting Ceramic Pours provide several advantages over other similar products. They boast excellent durability and provide excellent levels of heat retention. The cups also feature a highly efficient design and can be custom manufactured to meet specific needs.

Strict Quality Control

SEFU products passed the ISO 9001 quality system certification. All SEFU Investment Casting Ceramic Pours are subjected to rigorous quality control processes to ensure their quality, accuracy, and reliability.

Competitive Price

SEFU strives to offer competitive prices for Investment Casting Ceramic Pours in order to make them an excellent value for money. We also offer custom made orders that meet specific needs.

Complete Guide

Ceramic Pouring Cup

SEFU supplies casting pouring cups of various materials to suit different casting production processes. Available in Mullite ceramic pouring cups, ceramic fiber pouring cups, and refractory paper pouring cups for lost foam casting.

Let SEFU serve you to customize the casting pouring cup you need.

Ceramic Pouring Cups are made of high quality Mullite material that has excellent resistance to heat and chemical erosion.

The investment casting pour cups provide reliable protection for the surfaces of molds against the dangers posed by heat, pressure, and the risk of molten metal.

Ceramic pour cups feature excellent durability, heat retention, and thermal shock resistance. They are also highly efficient and provide outstanding protection against thermal damage, making them an ideal option for industrial production.

The Cups are widely used in industrial production for pouring molten metal into castings with very precise dimensions. They are often used for industrial applications such as the fabrication of mechanical parts, electrical components and other objects.

Ceramic Pouring Cups can be used in a variety of industrial applications. The cups should be placed on the surface of the molds and heated before the metal is melted. Then, the molds should be filled with molten metal in a fast and efficient manner.