Exothermic Riser Sleeves

These Feeders can reduce the rate of defective products. It can effectively increase the yield of the casting process and improve the density of the casting. The cooling rate of the foundry sleeve is slower than that of the casting and the foundry sleeve requires to accommodate enough material to develop the shrinkage of the casting.

- Avoid casting defects like shrinkage cavities in castings.

- Increase directional solidification.

- Soundness of the casting is improved.

- Less contact area.

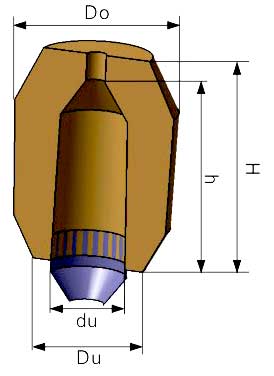

- Product Parameters

| Specification/Model (du*H) |

Effective modulus (cm) |

Riser size (mm) | Volume (CC) | ||||

| du | Du | Do | h | H | |||

| G08 | 0.85 | 21 | 40 | 56 | 50 | 62 | 14 |

| G10 | 1.0 | 30 | 45 | 63 | 65 | 80 | 38 |

| G12 | 1.2 | 25 | 50 | 78 | 85 | 100 | 36 |

| G12 | 1.2 | 30 | 54 | 68 | 80 | 94 | 45 |

| G13 | 1.3 | 42 | 60 | 80 | 95 | 110 | 109 |

| G17 | 1.7 | 42 | 62 | 87 | 95 | 107 | 109 |

| G17 | 1.7 | 42 | 62 | 90 | 100 | 115 | 112 |

| G19 | 1.9 | 40 | 66 | 105 | 99 | 118 | 111 |

| G22 | 2.2 | 50 | 76 | 110 | 100 | 120 | 156 |

| G23 | 2.3 | 50 | 90 | 130 | 100 | 120 | 156 |

| G25 | 2.5 | 50 | 90 | 137 | 118 | 140 | 201 |

| G28 | 2.8 | 60 | 100 | 136 | 125 | 140 | 274 |

| G32 | 3.2 | 65 | 100 | 150 | 126 | 145 | 327 |

Please contact the SEFU service team for detailed specifications on exothermic riser sleeves.

SEFU Exothermic Riser Sleeves Application

Riser sleeves are widely used in foundry industries such as iron and steel castings. It is used for low-pressure vibratory extrusion green sand lines. It can be placed in the cavity of the casting. It can also be used in high pressure molding lines and embedded cast iron production.

Exothermic Riser Sleeve Shape

These sleeves can be classified into Cylindrical sleeves, Oval sleeves, Neckdown sleeves, Torticollis sleeves, etc. These sleeves are high feeding efficiency and are made from light exothermic-insulation material.

Advantages of SEFU Exothermic Riser Sleeves

SEFU Exothermic Riser Sleeves help to improve the casting quality. It avoids casting defects and enables higher casting yields. It can be used in combination with Breaker Cores to reduce casting steps. It can be placed in the cavity of casting and helps to reduce the cost of casting production.

Related Products

Want to get more casting materials? SEFU team can serve you more.

FAQs About the Exothermic Riser Sleeves

The FAQ part helps you learn more about the Exothermic Riser Sleeves. If you have more questions about riser sleeves, put the SEFU team at your service. We look forward to exploring more about exothermic riser sleeves with you.

It is an additional material storage cavity that is added to avoid shrinkage or variability due to the material shrinkage in metal casting and can reduce mechanical strength.

The foundry sleeves can reserve molten metal, reinvigorate the molten metal when the metal shrinks, and avoid shrinkage holes on the casting.

It has the characteristics of reliable heat generation within a certain period of time, and there is a tiny fume when it heats up. These feeders will not expand under large metal pressure.