Ceramic Foam Filter

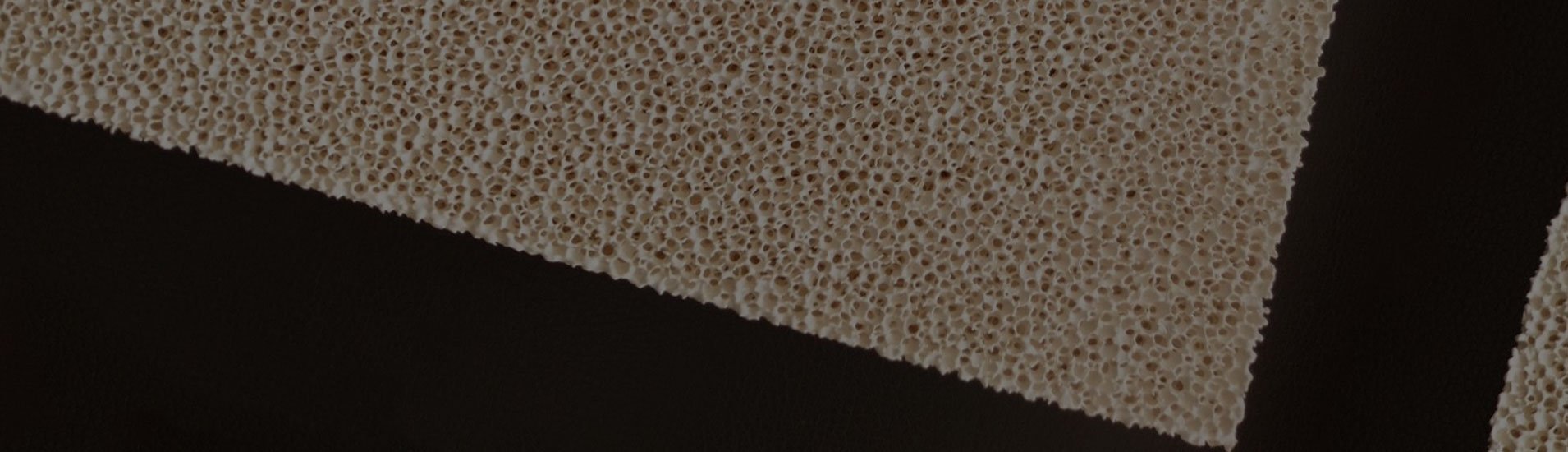

Ceramic foam filter has excellent filtering effect on molten metal.

The molten metal filters help to produce higher-quality castings with lower production costs. It removes impurities of all sizes, including impurities much smaller than the filter pores. It reduces turbulence to smooth and clean the flow of molten metal.

SEFU Ceramic Foam Filters Help Global Foundries Improve Casting Quality and Yield

- Precise sizes control during filter media sponge cutting to final sinter.

- High strength with enough slurry and free from loose debris, no break and no filter slag.

- Mature sintering technology to ensure high refractory and good thermal shock resistance.

- Good porosity and free from block during pouring molten metal.

Ceramic Foam Filter

Filtering molten metal using ceramic foam filters is a common practice in foundries. The materials for preparing ceramic foam filters mainly include ZrO2, Al2O3, SiC, etc.

Contact us if you need any help.

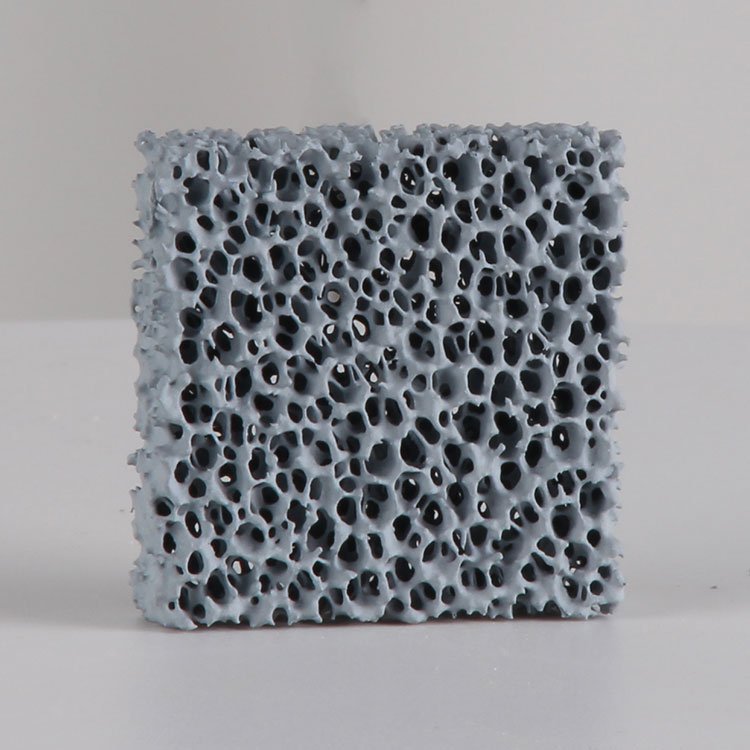

Silicon carbide ceramic foam filters based on SiC for filtration of iron and non-ferrous metals up to 1560 °C.

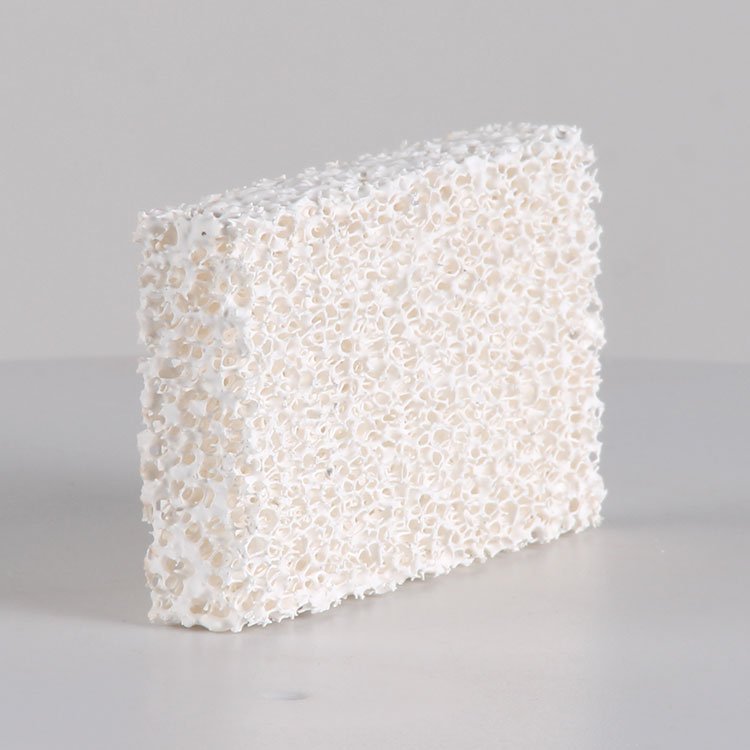

Alumina ceramic foam filters based on Al2O3 are suitable for filtering molten metals up to 1100 °C.

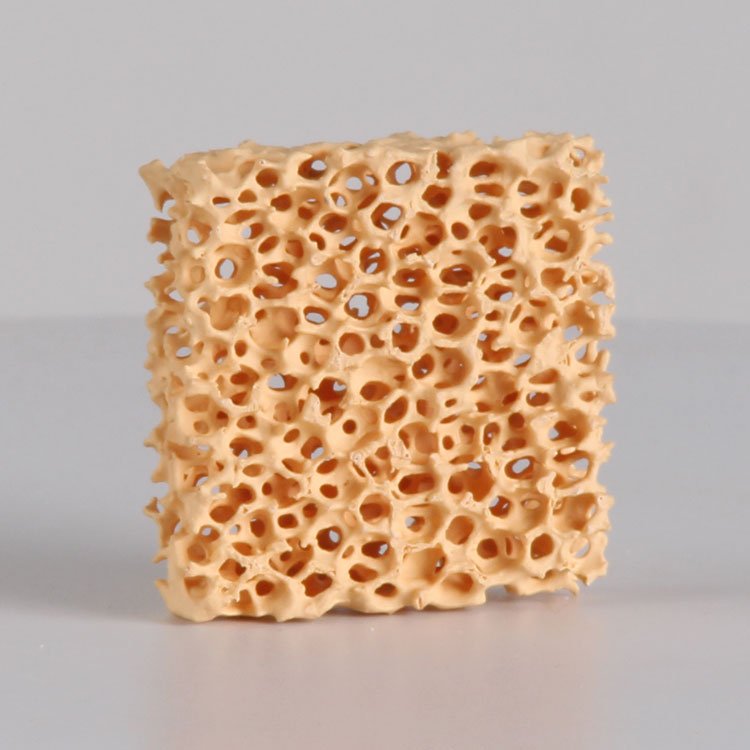

Zirconia Ceramic Foam Filters are made up of ceramics on the basis of partially stabilized ZrO2.

Which Ceramic Foam Filter Should You Choose?

Choosing SEFU Ceramic Foam Filters is the best choice for your foundry and metallurgy. There is always a filter for your castings.

SEFU filters can be customized according to your request

SEFU filters are suitable for iron, copper, aluminum, and steel alloys, etc.

Casting filters are available for 1700°C.

We supply you ceramic filter samples

High-Grade Raw Materials

SEFU ceramic foam filter uses high-quality polyurethane sponge as a raw material to ensure that the premium quality of the filter can meet your production needs.

Precise Cutting Machine

SEFU uses precision cutting machines to cut the polyurethane foam both vertically and horizontally, with great and well-organized controls the filter size to ensure that it is more satisfactory for your needs.

Multiple Production Lines

SEFU uses state of the art production equipment which is useful to meet your output requirements and shipping needs with multiple ceramic filter production lines.

What Can Ceramic Foam Filters Do?

Molten metal filtration uses ceramic foam filters worldwide.

Ceramic foam has been widely used in the global foundry industry due to its characteristics of high porosity, good air permeability, large specific surface area, and high thermal shock resistance.

Ceramic foam filters in air purifiers as photocatalyst filter carriers.

Foamed ceramic carrier has been widely used in the field of air filtration and purification due to their high porosity, high temperature resistance, chemical resistance, and recycling characteristics.

Different Shaped Filters for You

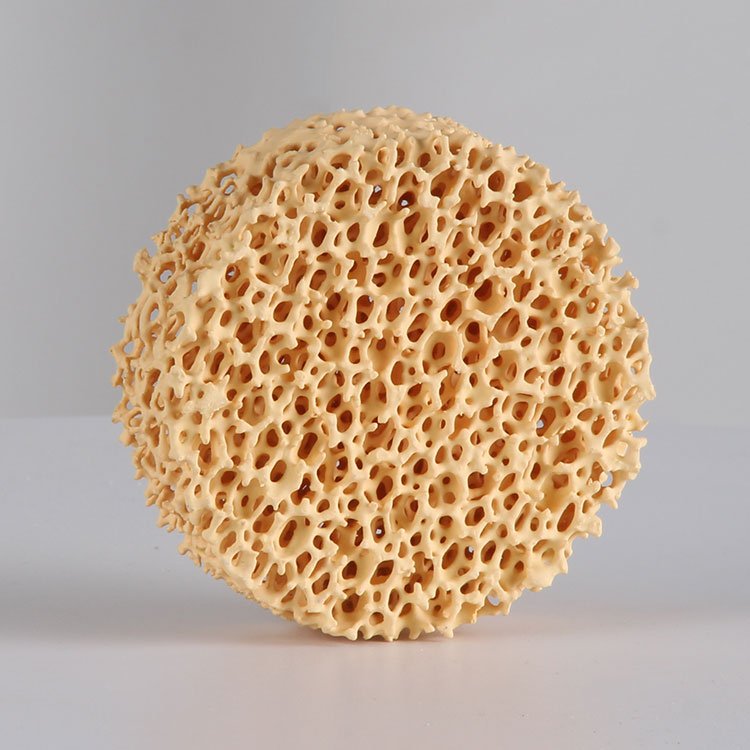

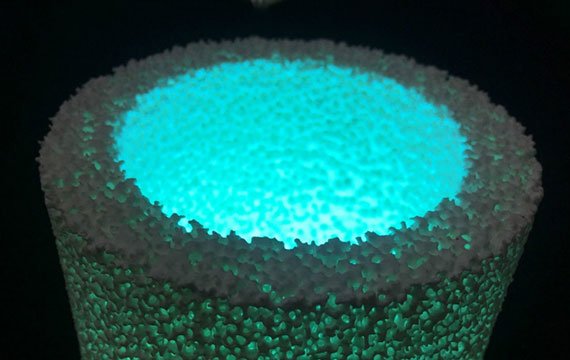

Customized silicon carbide filters in different shapes according to your requirements.

As a ceramic foam filter manufacturer, SEFU produces silicon carbide ceramic foam filters in unconventional shapes and sizes according to your needs.

Customized alumina ceramic filters in different shapes according to your requirements.

As a ceramic foam filter manufacturer, SEFU produces silicon carbide ceramic foam filters in unconventional shapes and sizes according to your needs.

Customized zirconia filters in different shapes according to your requirements.

As a ceramic foam filter manufacturer, SEFU produces silicon carbide ceramic foam filters in unconventional shapes and sizes according to your needs.

Choose Your Ceramic Foam Filter

- Our Packaging

- Data Sheet

| Item | SiC Ceramic Foam Filter | Alumina Ceramic Foam Filter | Zirconia Ceramic Foam Filter |

| Color | Grey/Black | White | Yellow |

| Pore Density | 10-40 PPI | 10-40 PPI | 10-40 PPI |

| Porosity | 80%-90% | 80%-90% | 80%-90% |

| Operating Temperature | ≤1500 ℃ | ≤1100 ℃ | ≤1700 ℃ |

| Bending Strength | ≥0.8 MPa | ≥0.6 MPa | ≥1.0 MPa |

| Thermal Shock Resistance | 6 Times/1100℃ | 6 Times/1100℃ | 6 Times/1100℃ |

| Application | Ductile Iron, Gray Iron, Other Cast Iron, and Non-ferrous Alloy | Aluminum, Aluminum Alloys, and Other Non-ferrous Alloys | Stainless Steel, Carbon Steel, and Large Cast Iron |

Related Product

FAQ about Ceramic Foam Filters

Would you like to learn more about ceramic filters?

Do you have any questions about ceramic foam filters?

Let us know! Let the ceramic foam filter manufacturer answer your questions.

The sponge we choose has uniform pores, good resilience, and small size shrinkage. Use a high-precision automatic die-cutting machine to ensure that the size of the sponge blank is accurate.

In the production process, each process self-checks the size. After the sintering is completed, the quality inspector will check the product size to ensure that it is qualified before leaving the factory.

Ensure the size and consistency of the carrier wells. After the sponge enters the factory, it will be measured with a special testing tool to ensure that the pore is qualified before it can be put into storage.

If you have special requirements for pore size, you can also send samples to us, and we will produce them according to your standard pores.

Now there are many orders for customized production according to customer needs, and take special products instead of general products.

This depends on your casting temperature and the material.

The alumina filter is used in the pouring of aluminum alloy castings, the temperature resistance is between 1100 °C.

Silicon carbide filters are used in gray iron, ductile iron, and copper alloy castings, with a temperature resistance of 1500 °C.

Zirconia filter is used in carbon steel, stainless steel, and alloy steel casting, temperature resistance of 1700 ℃.

As a ceramic foam filter manufacturer, we support customized products. We can customize the size and shape according to your needs. You provide us with drawings, our company’s technical staff will finally confirm whether it can be done.