Aluminium Foundry: Enhancing Aluminum Casting & Aluminium Alloy Quality

Explore a wide range of casting materials specifically designed for aluminum and aluminum alloy casting processes. Our offerings include high-quality products such as alumina ceramic foam filters, silicon carbide bonded particle filters, tap out cones, graphite rotors, auto sampling ladles, and thermocouples.

At SF-Foundry, we are committed to providing high-performance casting materials for the aluminum industry. Learn more about our products and how they can optimize your aluminum casting operations. Contact us today to discuss your specific requirements and discover the solutions we have to offer.

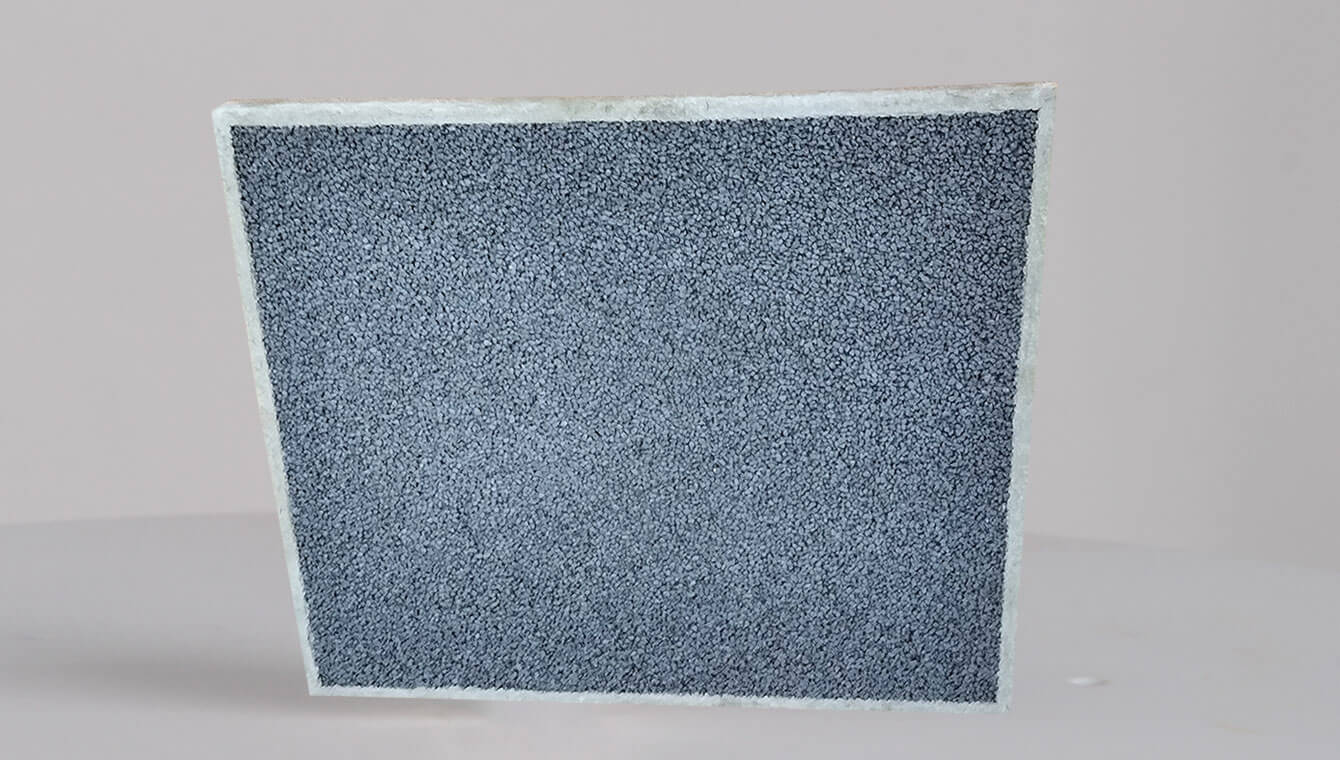

Alumina Ceramic Foam Filters

Alumina ceramic foam filters are essential tools for filtering aluminum and aluminum alloys, effectively removing impurities from the molten metal. Contribute to the production of high-quality aluminum castings.

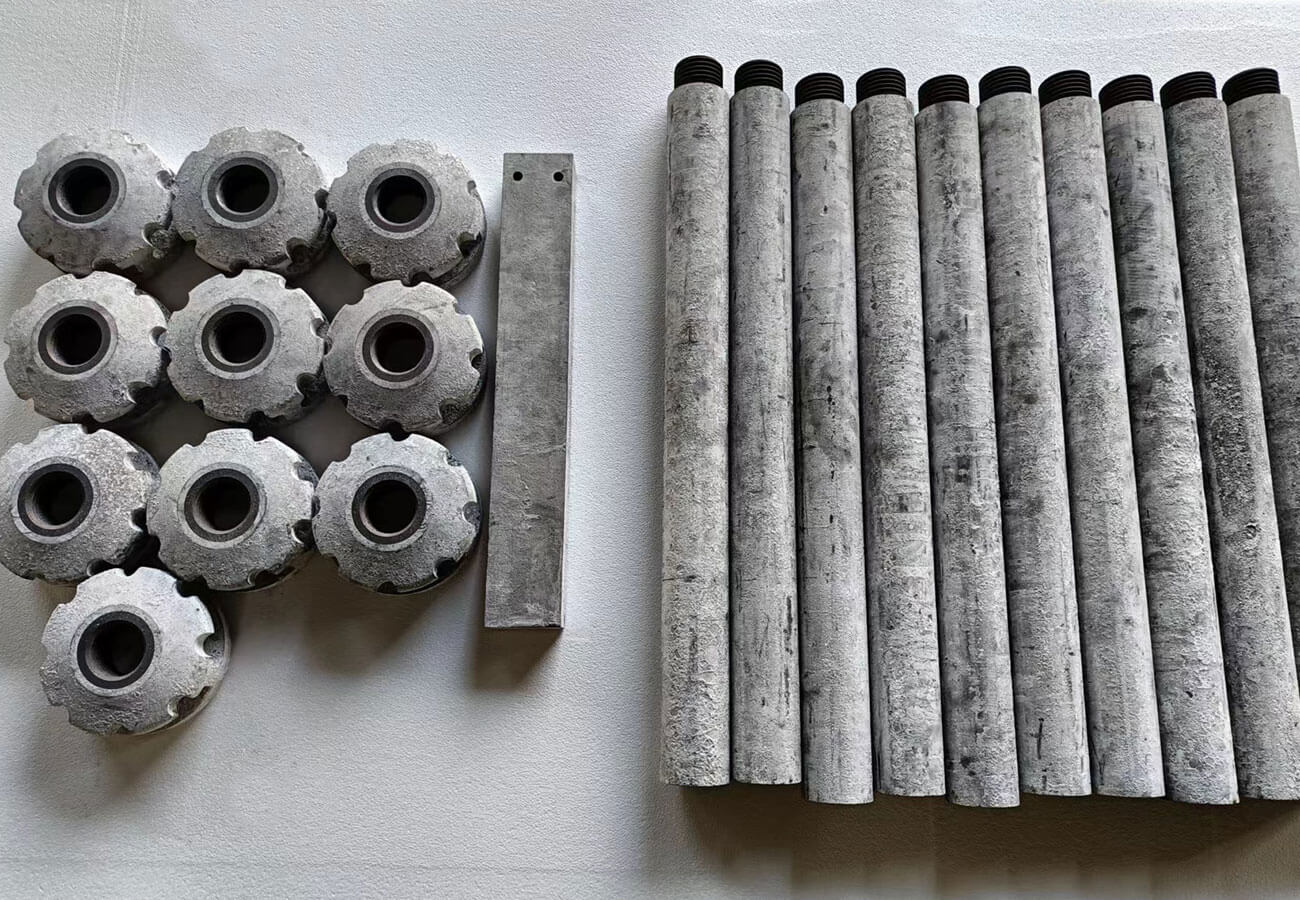

Silicon Carbide Bonded Particulate Filters

Silicon carbide (SiC) bonded particle filters are used in aluminum refining to filtrate extremely fine impurities in aluminum melt. These filters exhibit high strength and exceptional filtration efficiency. They are designed to remove minute particles and contaminants from molten aluminum, ensuring the production of high-quality aluminum products.

Tap Out Cone

The tap out cone is a crucial component used in the aluminum smelting process. It is specifically designed to control the flow of molten aluminum during casting. It features a tapered shape that allows for controlled pouring and tapping of the molten aluminum. It effectively regulates the flow rate and direction, ensuring a smooth and precise casting process.

Graphite Rotor

The antioxidant graphite rotor is a critical component used in the process of aluminum alloy smelting. It plays a crucial role in the removal of impurities from the metal during the purification process. The features high corrosion resistance. It efficiently purifies the metal through a vortex flow, resulting in high-quality output. Experience the benefits of our durable and efficient graphite rotors for aluminum alloy smelting. Contact us today for more information or a quote.

Auto Ladle

Auto Pouring Ladles revolutionize the aluminum casting process by offering automated and precise transfer of molten metal. The ladles improve casting efficiency, minimize defects, and enhance product quality, resulting in higher yields and superior finished products. Upgrade your aluminum casting process with Auto Pouring Ladles and experience enhanced efficiency and quality.