Alumina Filters

Alumina filters are suitable for aluminum and aluminum alloy casting. SEFU can be manufactured in all standard sizes and different thicknesses.

- Superior dimensional tolerances.

- Reduce scrap related to inclusions

- Reduce costs related to inclusion defects.

- Increase productivity with higher extrusion or rolling speeds.

- Increase casting flexibility with easy alloy changes.

- Regular Sizes and Filtration Capacity

- Our Certification

| Size (mm) |

Flow Rate (kg/s) |

Capacity (kg) |

| 30*50*22 | 5 | 90 |

| 40*40*22 | 5 | 96 |

| 50*50*22 | 7 | 150 |

| 75*50*22 | 10 | 225 |

| 100*50*22 | 13 | 300 |

| 75*75*22 | 15 | 338 |

| 100*75*22 | 20 | 450 |

| 100*100*22 | 26 | 600 |

| 150*100*22 | 40 | 900 |

| 150*150*22 | 60 | 1350 |

| 200*200*40 | 100 | 2400 |

| Φ40*11 | 5 | 75 |

| Φ50*22 | 6 | 118 |

| Φ60*22 | 8 | 170 |

| Φ70*22 | 10 | 231 |

| Φ80*22 | 12 | 301 |

| Φ90*22 | 16 | 382 |

| Φ100*22 | 18 | 471 |

| Φ150*22 | 40 | 1060 |

| Φ200*30 | 70 | 1884 |

Selected Raw Materials

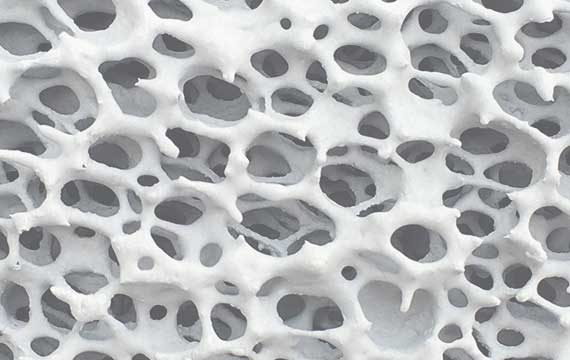

SEFU Alumina Filters use high grade sponges and slurries to produce reliable quality ceramic filters. The porosity of SEFU ceramic filter can reach 90%, high temperature resistance 1200℃, high strength and strong thermal shock resistance.

Precise Cutting Instrument

SEFU alumina ceramic filters use precise cutting instruments to cut polyurethane sponges. It guarantees precise dimensions and tolerances for ceramic foam filters. It can be used with confidence in the production of precision castings.

Strict Quality Control

SEFU is an ISO9001: 2015 certified company. SEFU alumina filter strictly controls product quality through various processes, so that it has extremely high strength and thermal shock resistance in the process of filtering molten aluminum or gas.

FAQs About the Alumina Filter

SEFU Alumina Filters are refractory porous ceramic filters. It’s versatile. Let’s know more about the alumina ceramic filter.

Alumina filters are porous ceramic foam filters made of polyurethane sponge. It can be used to filter molten metal or gas.

It has a three-dimensional structure. Through its special structure, it can block the capture and adsorption to effectively remove oxide inclusions and other non-metallic inclusions. Whether it is a complex large piece or a precision part after filtering, the product quality will get a satisfactory result.

It has the characteristics of light weight. It has high mechanical strength, large specific surface area and high porosity. It has excellent thermal shock resistance, chemical resistance and high temperature stability in molten metals.

Alumina alloys and non-ferrous, high temperature gas filters, catalyst substrate, etc. Such as TiO2 photocatalytic filters for air purifiers.