Riser Sleeves Solve Your Casting Problems

- Manufacturer of riser sleeves for the iron, steel, and non-ferrous foundry industry.

- Available in vacuum formed ceramic fiber construction.

- Types include straight, dome, round neck down, direct pour cup and breaker core insert sleeves

Riser Sleeves

In iron and steel castings where they mainly use riser sleeves. These are widely used in the foundry industry. Riser sleeves are resin-bonded with exothermic or insulating material etc.

A Type exothermic riser sleeve is mainly used for the production of iron castings.

B Type exothermic riser sleeve is mainly used in the production of steel castings.

G Types can be used as iron and steel castings to extend feed capacity.

Multiple Production Lines

SEFU exothermic riser sleeves ensure the exothermic function on the basis of heat preservation. We have multiple production lines to produce riser sleeves to ensure the quality and delivery for you on schedule.

Sufficient Stock

SEFU exothermic riser sleeves are available in a wide variety and are fully stocked. We can ship to you at any time to ensure that you receive your exothermic riser sleeve product within the estimated deadline.

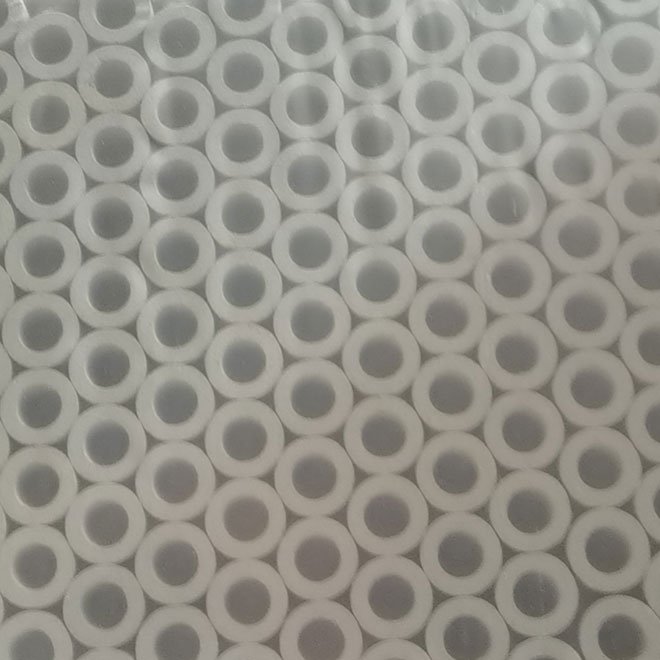

Breaker Core

SEFU can supply you with the breaker core matched with the exothermic riser sleeve. It is more convenient for you to remove the feeding riser sleeve, helping you save labor and production costs.

What can exothermic riser sleeves be used for?

SEFU exothermic riser sleeves can be used for feeding iron castings. It can meet the production of iron castings and solve the problems of shrinkage cavity and shrinkage porosity of iron castings.

SEFU exothermic riser sleeves can also play an important role in the production process of steel castings. Sleeves are used in the steel casting process to compensate for the shrinkage of the steel during solidification.

Insulating sleeves are used for feeding all grades of iron casting. The riser linings are made of low-density and refractory materials so as to provide insulation to the riser metal in moulds.

Exothermic-insulating riser sleeve is one of the chart topping riser sleeves. It is suitable for manufacturing of medium and large iron castings and steel castings.

High Exothermic sleeve can be fixed directly on an area to target shrinkage. The product can be used as riser foremost for iron and steel castings, extending the solidification time and extending the feeding capacity of the riser.

More About Exothermic Sleeves

- Our Packaging

Related Product

FAQ About Exothermic Sleeves

Riser sleeves used in steel casting are generally formulated as purely insulating or exothermically insulating, where a thermite reaction is typically used for heat generation.

It helps to solve the problem of shrinkage cavities and shrinkage porosity in castings. In addition to the function of feeding, it also has the role of exhaust and slag collection.

It has a good exothermic effect and high feeding efficiency. It helps to increase the casting yield and helps to reduce the cost of casting production.