Silicon Carbide Foam Filter

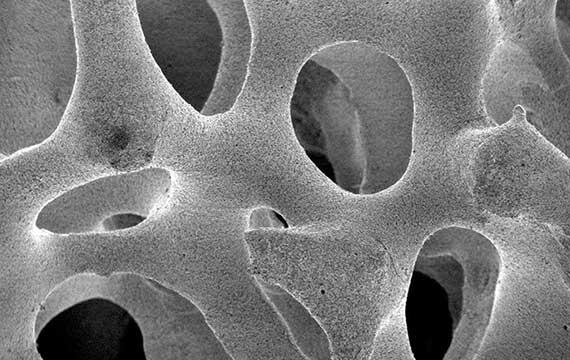

SEFU Silicon Carbide Foam Filter is the most common porous ceramic. It is currently the most promising inorganic high-temperature material. Silicon carbide ceramic foam filters are used to reduce the slag in molten iron. It improves the tensile strength of castings.

- Branded main raw material to ensure stable quality.

- Precise sizes control during filter media sponge cutting to final sinter.

- High strength with enough slurry and free from loose debris, no break and no filter slag.

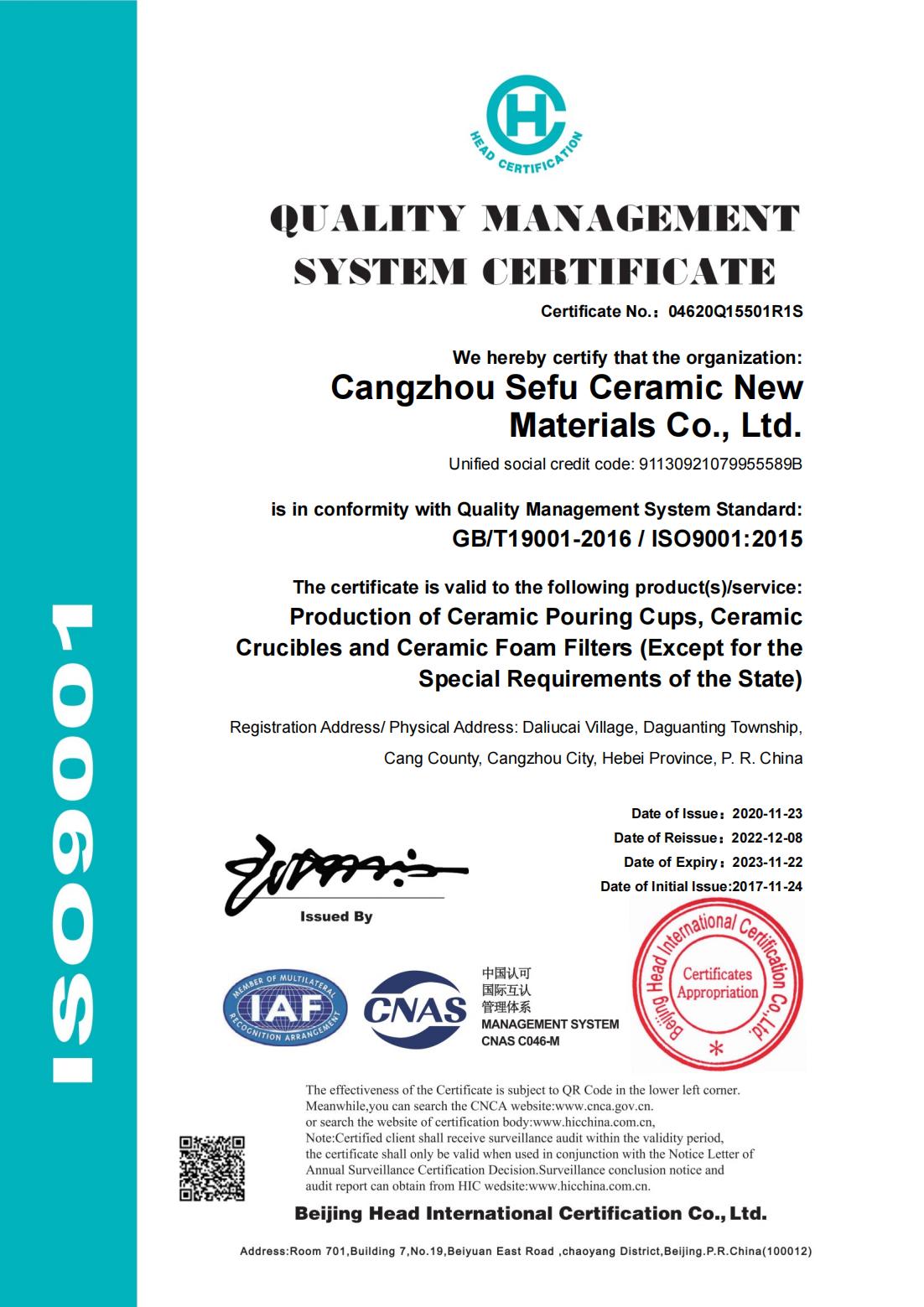

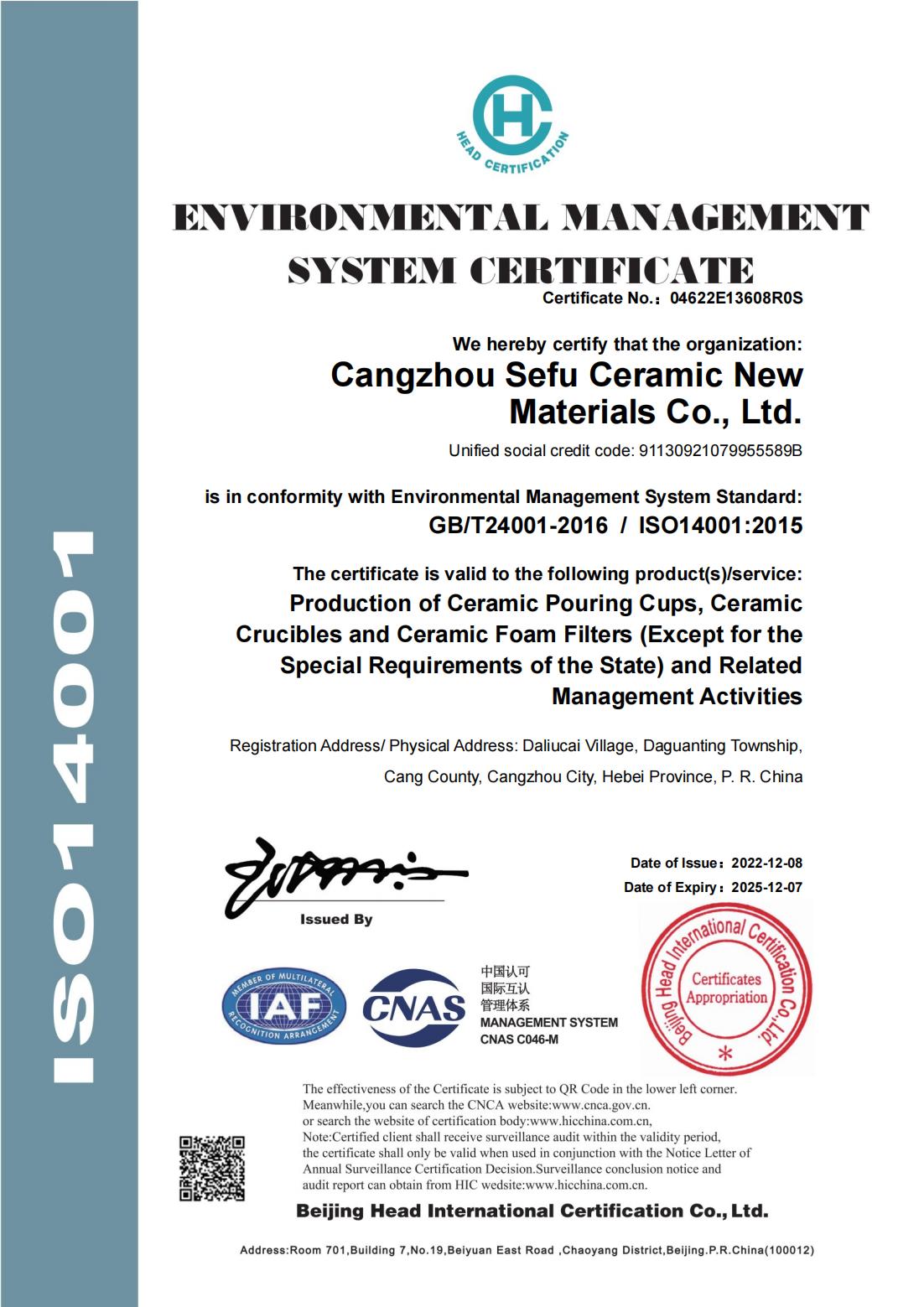

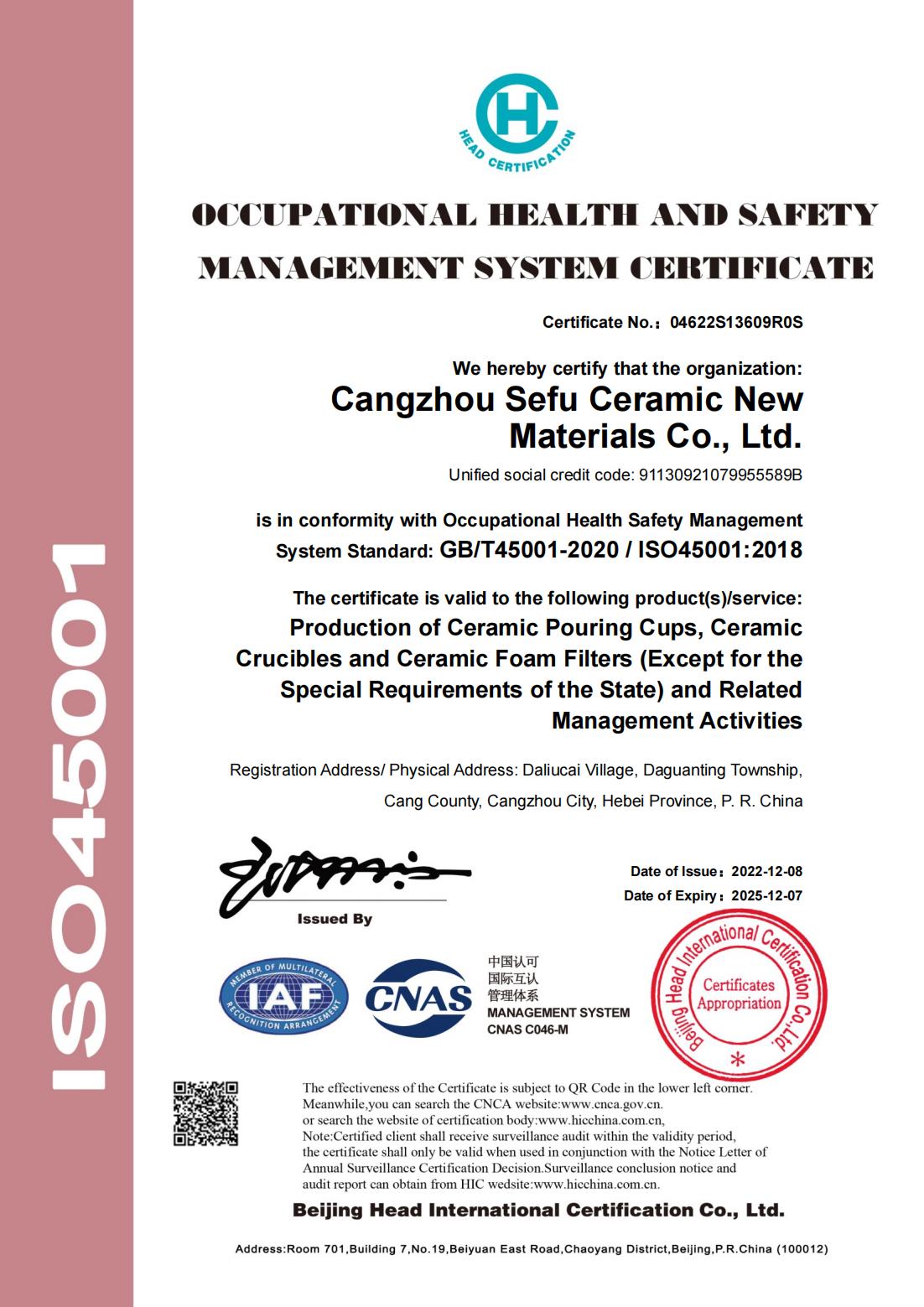

- Regular Sizes and Filtration Capacity

- Our Certification

| Size (mm) |

10ppi | 20ppi | 30ppi | |||||

| Capacity (kg) |

Flow Rate (Kg/s) |

Capacity (kg) |

Flow Rate (kg/s) |

Capacity (kg) |

Flow Rate (kg/s) |

|||

| Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | Grey Iron |

Grey Iron |

Grey Iron | Grey Iron | |

| 40×40×15 | 64 | 32 | 4 | 3 | 50 | 3 | 42 | 2 |

| 40×40×22 | 64 | 32 | 4 | 3 | 50 | 3 | 42 | 2 |

| 50×30×22 | 60 | 30 | 4 | 3 | 47 | 3 | 40 | 2 |

| 50×50×15 | 100 | 50 | 6 | 4 | 78 | 3.5 | 66 | 3 |

| 50×50×22 | 100 | 50 | 6 | 4 | 78 | 3.5 | 66 | 3 |

| 60×60×15 | 144 | 72 | 9 | 6 | 112 | 6 | 95 | 5 |

| 75×50×22 | 150 | 75 | 9 | 6 | 116 | 6 | 99 | 5 |

| 75×75×22 | 220 | 110 | 14 | 9 | 175 | 10 | 149 | 8 |

| 100×50×22 | 200 | 100 | 12 | 8 | 155 | 9 | 133 | 7 |

| 100×75×22 | 300 | 150 | 18 | 12 | 232 | 13 | 199 | 11 |

| 100×100×22 | 400 | 200 | 24 | 16 | 310 | 18 | 265 | 15 |

| 150×150×22 | 900 | 450 | 54 | 36 | 698 | 40 | 596 | 33 |

| 200×200×40 | 1600 | 800 | 95 | 64 | 1240 | 58 | 1060 | 48 |

| Dia 40×22 | 40 | 20 | 3 | 2 | 39 | 2 | 33 | 2 |

| Dia 50×22 | 70 | 35 | 4.5 | 3 | 61 | 4 | 52 | 3 |

| Dia 60×22 | 100 | 50 | 6.5 | 4.2 | 88 | 5 | 75 | 4 |

| Dia 70×22 | 150 | 75 | 8.8 | 5.5 | 119 | 7 | 102 | 6 |

| Dia 75×22 | 170 | 88 | 10 | 6 | 137 | 8 | 117 | 6.5 |

| Dia 80×22 | 200 | 100 | 11 | 7.2 | 156 | 9 | 133 | 7 |

| Dia 90×22 | 240 | 120 | 14 | 9 | 197 | 11 | 169 | 9 |

| Dia 100×22 | 280 | 140 | 17 | 11 | 243 | 14 | 208 | 12 |

| Dia 125×22 | 400 | 220 | 24 | 16 | 380 | 22 | 325 | 18 |

| Dia 150×22 | 700 | 350 | 38 | 25 | 548 | 32 | 468 | 26 |

| Dia 200×40 | 1240 | 620 | 67 | 44 | 973 | 56 | 832 | 46 |

Silicon Carbide Foam Filter Features

SEFU Silicon carbide foam filter has three-dimensional interconnected channels and is a porous ceramic shaped like foam. It has the advantages of high porosity, high thermal conductivity, high mechanical strength, oxidation resistance, and corrosion resistance.

SEFU Silicon Carbide Foam is generally immediately available in most volumes.

Silicon Carbide Foam Filters for Foundry Industry

SEFU Silicon carbide filter can remove inclusions in molten metal at 1560°C. It reduces the surface defects of castings, reduces the re-oxidation defects inside castings, and reduces the rejection rate of castings.

It is suitable for auto parts, diesel engine parts, compressors, wind power castings, high-end machine tool castings, etc.

Silicon Carbide Foam Filters for Environmental Industry

SEFU Silicon carbide ceramic foam filter can be used as catalyst substrate. After coating the catalyst, it has an antibacterial effect and can effectively remove harmful gases in the air, such as formaldehyde, benzene, ammonia, and TVOC.

It is suitable for air purifiers, air conditioners, lamps, and air sterilizers equipped with photo-oxygen catalytic functions.

FAQs About the Silicon Carbide Foam Filter

What else would you like to know about Silicon Carbide Ceramic Foam Filters? Leave your questions and let our experienced engineers help you.

It has the advantages of lightweight, high strength, high-temperature resistance, corrosion resistance, long service life, and good filter adsorption.

Silicon carbide ceramic foam can be sintered and compacted under atmospheric pressure and can be compacted without high pressure and inert atmosphere, which reduces the production cost of enterprises.