CHOOSE YOUR CASTING FILTERS NOW

Foundry filters are used in the casting process to purify liquid casting alloys, reduce or eliminate various non-metallic inclusions and exhaust problems during casting.

SEFU has a variety of materials for foundry filters available to you. Let’s choose the most suitable filter for your foundry.

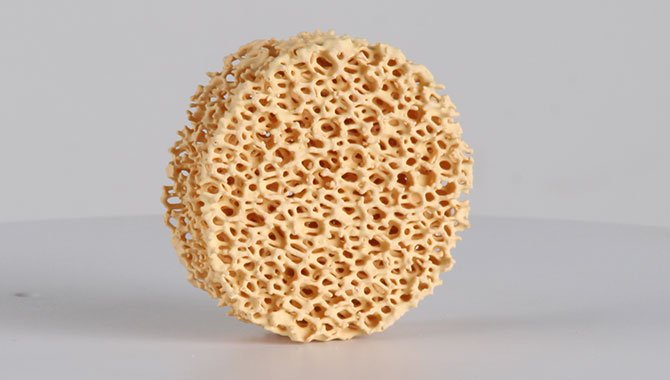

Silicon Carbide Ceramic Foam Filter

Silicon carbide (SiC) ceramic foam filters are primarily used for filtration in casting processes involving iron and non-ferrous alloys. The porous ceramics structure allows for the efficient removal of impurities and contaminants from molten metal, resulting in improved casting quality.

These ceramic filters play a crucial role in enhancing the mechanical properties and overall integrity of cast components in various industries, including automotive, aerospace, and manufacturing.

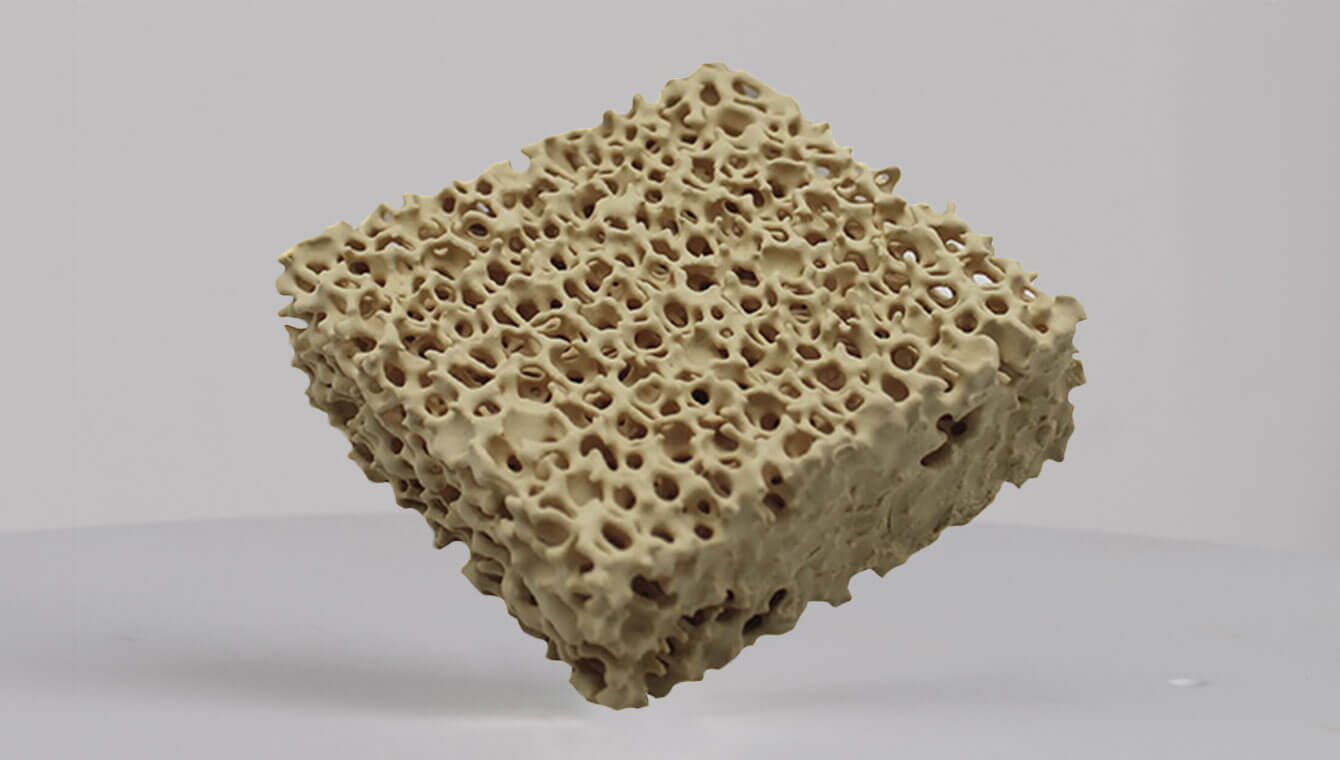

Alumina Ceramic Foam Filter

Alumina ceramic foam filters are primarily utilized for filtration in casting processes involving aluminum and aluminum alloys. They effectively capture solid particles, oxides, and other unwanted substances, resulting in cleaner and higher-quality castings.

These ceramic filters play a crucial role in improving the mechanical properties and overall integrity of cast components in aluminum foundries and smelters.

Zirconia Ceramic Foam Filter

Zirconia ceramic foam filters are specifically designed for filtration in processes involving steel and high-temperature alloys. These ceramic filters allow for effective filtration and purification of molten metal in steelmaking and high-temperature alloy casting withstanding temperatures up to 1700°C.

Aluminum Casting Filter

Aluminum casting filters are specifically developed to filter impurities in aluminum and aluminum alloys during the casting process. These filters are designed to be used when molten metal enters the mold in aluminum casting. The primary purpose of aluminum casting filters is to effectively capture and remove various impurities, such as solid particles, oxides, and dross, from the aluminum and aluminum alloy melt. By removing these impurities, the filters help improve the overall quality of castings, ensuring they meet desired specifications and standards.

Magnesia Ceramic Foam Filters

Magnesia ceramic foam filters are specifically designed for filtration in casting processes involving magnesium and magnesium alloys with excellent thermal stability and chemical resistance. The ceramic filters effectively capture solid particles, oxides, and other undesirable substances, ensuring cleaner and higher-quality castings.

These ceramic filters play a critical role in enhancing the mechanical properties and overall integrity of cast components in the magnesium foundry industry.

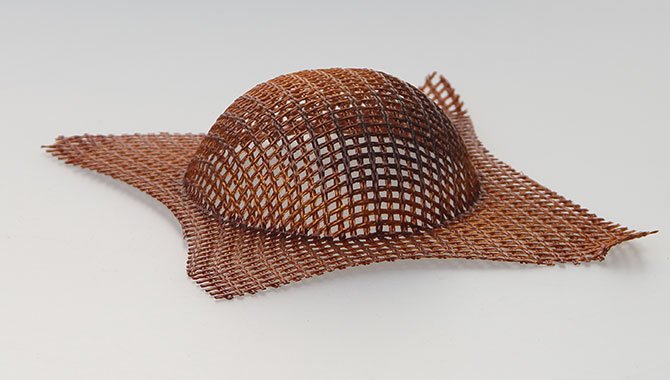

Fiberglass Mesh Filter

Fiberglass mesh filters are high-performance inorganic non-metallic materials used for the effective removal of slag, refractory material particles, and non-metallic inclusions from molten metal. These filters are made from glass fiber.

Fiberglass mesh filters are widely used in various industries, including foundries and metal casting, where they play a crucial role in improving the casting quality by removing unwanted particulates and impurities.

Honeycomb Ceramic Filter

Honeycomb ceramic filters, widely used in the metallurgical and casting industries, are characterized by their large surface area, high mechanical strength, and excellent thermal shock resistance.

The ceramic filters exhibit exceptional resistance to thermal shock. They play a vital role in improving the quality of metallurgical processes and castings by efficiently removing contaminants and ensuring the desired purity of the final product.

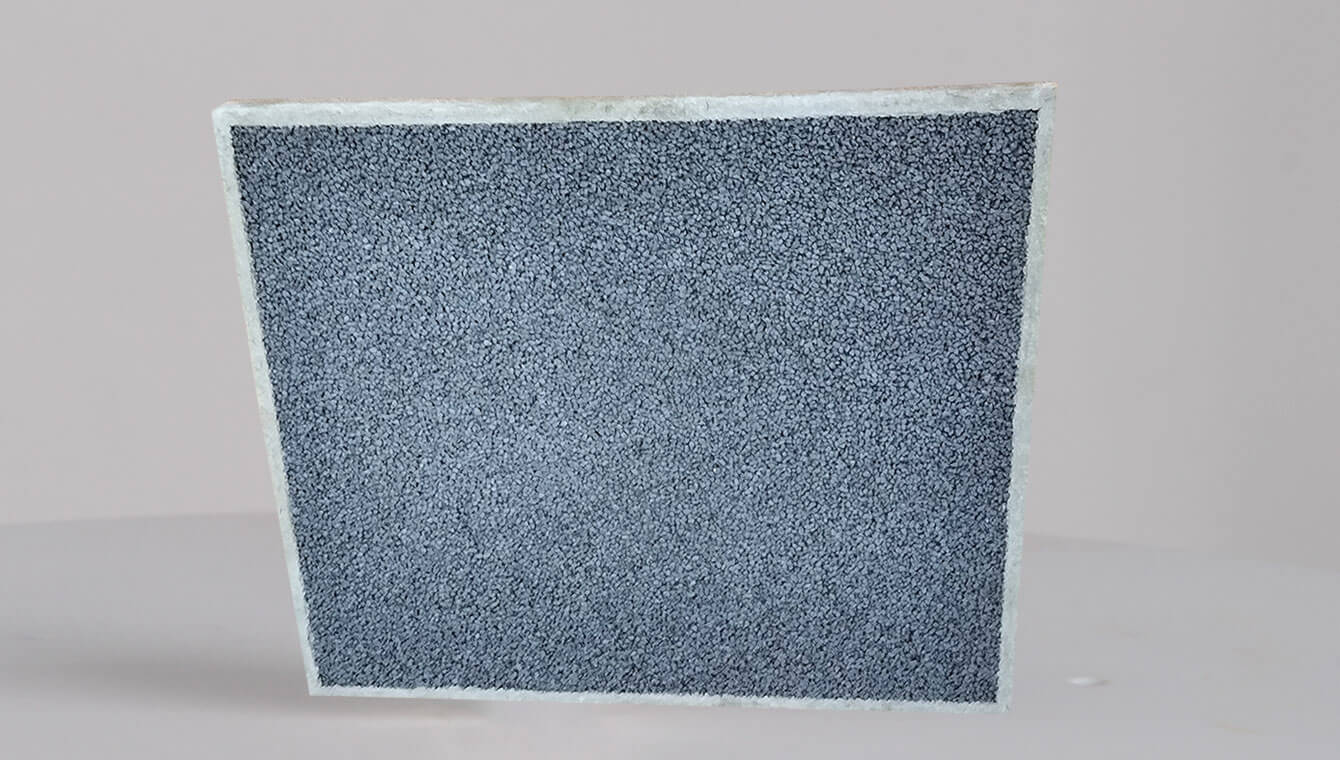

Silicon Carbide (SiC) Bonded Particle Filters

Silicon carbide (SiC) bonded particle filters are used in aluminum refining to filtrate extremely fine impurities in aluminum melt. These filters exhibit high strength and exceptional filtration efficiency. They are designed to remove minute particles and contaminants from molten aluminum, ensuring the production of high-quality aluminum products.