Paper Casting Runner

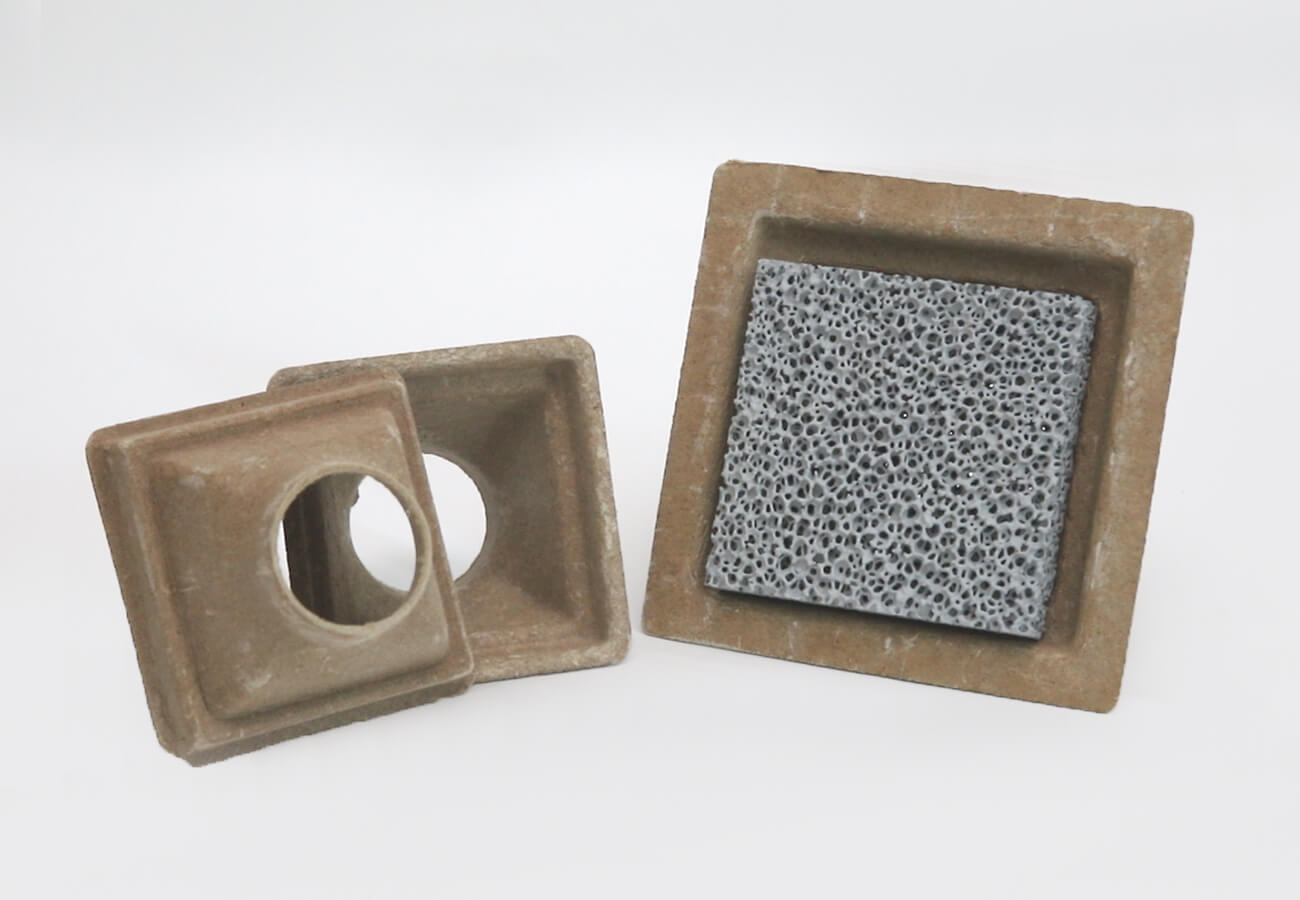

The Paper Casting Runner is an advanced molding technology that replaces traditional refractory ceramic runners in the casting process.

It is an essential part of the gating system components used in accurate casting, and it serves many applications, including iron filtration. It improves flow distribution, minimizes non-metallic impurities in molten metal, and improves casting efficiency.

- High-Temperature Resistance

- Lightweight and Easy to Handle

- Customizable to Iron & Steel Casting Application

- Environmentally Friendly Materials

- Resistant to Corrosion and Thermal Shock Resistance

Sustainability in Iron Casting Applications

A featherweight yet powerful solution for running and gating system components, the Paper Casting Runner from Cangzhou Sefu Ceramic New Materials Co., Ltd. is designed especially for heavy iron castings manufacture. Heavy casting procedures can benefit greatly from the runner’s simple assembly that is ensured by its push-fit connectors.

Its unique breakdown qualities help to fully incorporate this product into the current sand recycling system. Due to its ability to reduce or eliminate issues with sand recycling, the Paper Casting Runner is an economical and environmentally friendly option for modern foundries looking to increase productivity and cut waste.

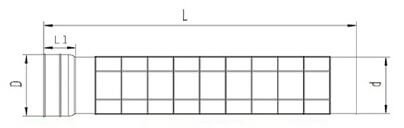

- Pouring Straight Pipe

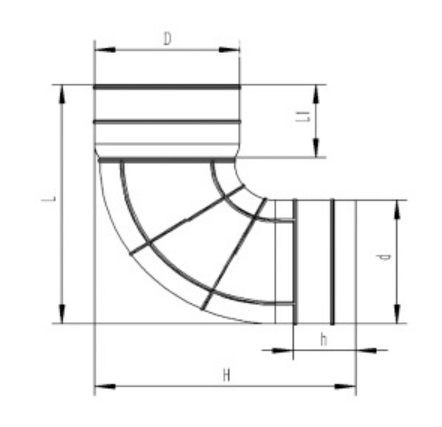

- Pouring Elbow

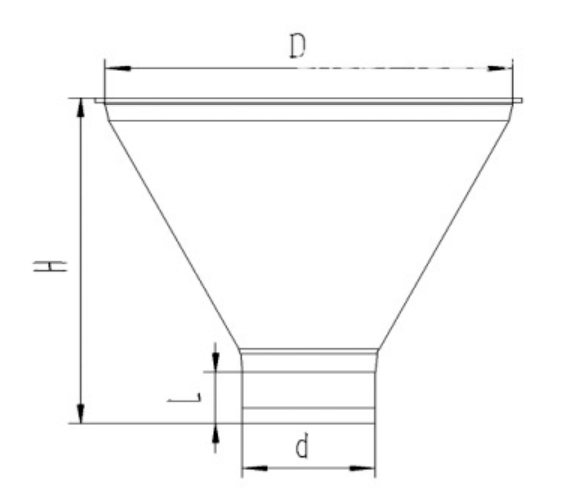

- Casting Pouring Cup

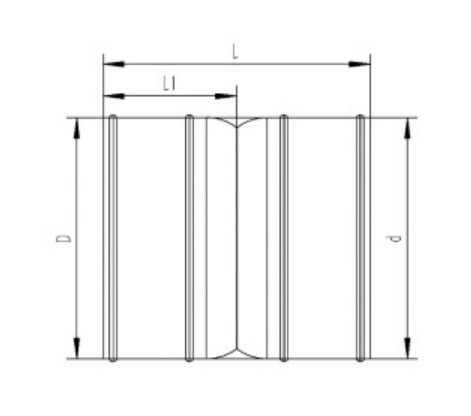

- Pouring Sprue Connector

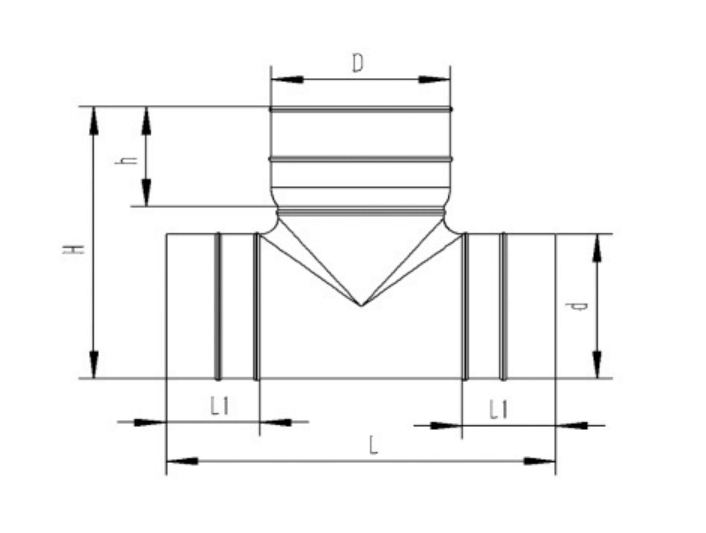

- Pouring Runner Tee

| Item | Size | Diameter | L | L1 | D | d |

| JDZ-25 | Φ25*300 | Φ25 | 300 | 30 | 30.2 | 27.3 |

| JDZ-30 | Φ30*300 | Φ30 | 300 | 30 | 35.2 | 32.4 |

| JDZ-35 | Φ35*300 | Φ35 | 300 | 30 | 40.8 | 38 |

| JDZ-40-32 | Φ40-32*300 | Φ40 | 300 | 30 | 46.6 | 35.4 |

| JDZ-40 | Φ40*300 | Φ40 | 300 | 30 | 46.6 | 43.4 |

| JDZ-50 | Φ50*300 | Φ50 | 300 | 30 | 57.7 | 54 |

| JDZ-60 | Φ60*300 | Φ60 | 300 | 30 | 67.7 | 64 |

| JDZ-70 | Φ70*300 | Φ70 | 300 | 30 | 79.5 | 75 |

| JDZ-80 | Φ80*300 | Φ80 | 300 | 30 | 90.6 | 85.5 |

| JDZ-90 | Φ90*300 | Φ90 | 300 | 30 | 103.2 | 97 |

| JDZ-100 | Φ100*300 | Φ100 | 300 | 30 | 113.3 | 107 |

| Item | Specification | L | L1 | H | h | D | d |

| JDW-25 | 90° | 68 | 30 | 68 | 30 | 30.3 | 30.3 |

| JDW-30 | 90° | 73 | 30 | 73 | 30 | 35.8 | 35.8 |

| JDW-35 | 90° | 80 | 30 | 80 | 41.2 | 38 | |

| JDW-40-30 | Variable Diameter Tube | 72.5 | 30 | 90 | 46 | 32.5 | |

| JDW-40 | 90° | 90 | 30 | 90 | 46.9 | 43.4 | |

| JDW-50 | 90° | 104 | 30 | 104 | 58 | 54 | |

| JDW-50-30 | Variable Diameter Tube | 70 | 30 | 87 | 58.1 | 32.4 | |

| JDW-60 | 90° | 116 | 30 | 116 | 68.7 | 64 | |

| JDW-70 | 90° | 130 | 30 | 130 | 80 | 75 | |

| JDW-80 | 90° | 140 | 30 | 140 | 91.2 | 85.5 |

| Item | Specification | H | D | d | Remark |

| JBP-130-40 | Φ130 x Φ40 | 130 | 130 | 40 | Eccentric |

| JB-130-40 | Φ130 x Φ40 | 130 | 130 | 40 | Cone |

| JB-140-50 | Φ140 x Φ50 | 115 | 140 | 50 | Cone |

| JB-160-50 | Φ160 x Φ50 | 150 | 160 | 50 | Cone |

| JB-160-60 | Φ160 x Φ60 | 120 | 160 | 60 | Cone |

| JBP-200-40 | Φ200 x Φ40 | 135 | 200 | 40 | Eccentric |

| JBP-200-50 | Φ200 x Φ50 | 135 | 200 | 50 | Eccentric |

| JBP-200-60 | Φ200 x Φ60 | 135 | 200 | 60 | Eccentric |

| JBP-200-60 | Φ200 x Φ60 | 220 | 200 | 20 | Eccentric Thickening |

| JBP-200-70 | Φ200 x Φ70 | 160 | 200 | 70 | Eccentric Thickening |

| JB-260-70 | Φ260 x Φ70 | 280 | 260 | 70 | Round |

| JB-260-90 | Φ260 x Φ90 | 280 | 260 | 90 | Round |

| Item | Size | L | L1 | D | d |

| JDJ-30/30 | Φ30-30 | 50 | 25 | 35.2 | 35.2 |

| JDJ-40/40 | Φ40-40 | 50 | 25 | 46.6 | 46.6 |

| JDJ-40-40 | Φ40-40 | 50 | 25 | 46.5 | 43.4 |

| JDJ-40-35 | Φ40-35 | 75 | 30 | 46.9 | 38 |

| JDJ-40-40*20 | Φ40-40×20 | 60 | 22 | 47.3 | 40×20 |

| JDJ-50/50 | Φ50-50 | 50 | 25 | 58 | 58 |

| JDJ-50-50 | Φ50-50 | 50 | 25 | 58 | 54 |

| JDJ-50/40/30 | Φ50-40-30 | 81 | 25 | 58.1 | 32.4 |

| JDJ-50/30 | Φ50-30 | 80 | 30 | 58.1 | 32.4 |

| JDJ-60/60 | Φ60-60 | 50 | 25 | 68 | 68 |

| JDJ-70/70 | Φ70-70 | 60 | 30 | 80 | 80 |

| Product name | Item | Size | L | L1 | H | h | D | d |

| Reducing Tee | JDS-50/30 | Φ50-30-30 | 125 | 32 | 80 | 30 | 58.5 | 32.4 |

| JDS-50/35 | Φ50-35-35 | 148 | 40 | 80 | 30 | 58.1 | 38 | |

| JDS-60/50 | Φ60-50-50 | 155 | 18 | 103 | 30 | 68.1 | 54 | |

| JDS-70/50 | Φ70-50-50 | 140 | 24 | 92 | 30 | 80 | 54 | |

| JDS-90/70 | Φ90-70-70 | 180 | 34 | 122 | 30 | 105 | 75 | |

| JDS-30/70/70 | Φ40(30)-70-70 | 100 | 26 | 130 | 50 | 40.6 | 80 | |

| JDS-50/70/70 | Φ50-70-70 | 140 | 38 | 110 | 28 | 54 | 79.5 | |

| JDS-40/60/60 | Φ40-60-60 | 125 | 35 | 117 | 48 | 43.7 | 68 | |

| JDS-30/40/40 | Φ40-40-30 | 100 | 28 | 90 | 43 | 32.5 | 46 | |

| JDS-30/50/50 | Φ30-50-50 | 105 | 35 | 83 | 33 | 32.4 | 54 | |

| Equal Tee | JDS-30/30/30 | Φ30-30-30 | 98 | 30 | 70 | 30 | 35.5 | 35.5 |

| JDS-35/35/35 | Φ35-35-35 | 100 | 30 | 73 | 30 | 41.7 | 41.7 | |

| JDS-40/40/40 | Φ40-40-40 | 102 | 25 | 82 | 30 | 47 | 43.4 | |

| JDS-50/50/50 | Φ50-50-50 | 124 | 32 | 96 | 30 | 58.7 | 54 | |

| JDS-60/60/60 | Φ60-60-60 | 106 | 17 | 103 | 30 | 68.1 | 64 | |

| JDS-70/70/70 | Φ70-70-70 | 140 | 28 | 112 | 30 | 80.5 | 75 | |

| Reducing Cross | JD4T-50/30 | Φ50-50-30-30 | 120 | 30 | 104 | 30 | 57.5 | 36 |

Advantages of the Paper Casting Runner

- Lightweight, Durable: Simple handling and installation, reducing labor costs and improving overall operational productivity

- Sustainable and Eco-Friendly: Crafted from recycled pulp, our Paper Casting Runner reduces waste, minimises heat loss, and increases energy conservation.

- Improved Casting Quality: Enhances flow distribution, decreases non-metallic inclusions, and lowers post-production treatments for cleaner, more precise castings.

- Waste Reduction & Easy Cleanup: Produces minimal residue, simplifies post-casting cleanup, and minimises disposal costs for cleaner, more efficient operations.

- Optimal Thermal Insulation: Exceptional heat retention enhances casting quality and longevity while reducing material waste.

Applications

The Paper Casting Runner is tailored for use in demanding casting processes, including lost foam casting and other complex molding technologies. It is highly adaptable across industries that require precision and consistency in casting operations. From aviation to automotive manufacturing, this product delivers superior performance and efficiency.

The Paper Casting Runner is created to be used in lost foam casting and other intricate molding techniques. It can be used in many industries where casting operations need to be consistent and accurate. This product offers exceptional performance and efficiency in many industries.

Key businesses benefiting from the Paper Casting Runner:

-

- Aviation: High-Quality, Lightweight Casting For Aircraft Components Such As Brackets, Frames, And Engine Parts

- Automobiles: Advanced Metal Casting Techniques For Automotive Engines

- Railways: Durable Components For Railway Machineries Such As Axles, Wheels, And Frames.

- Wind Power: Accurate Casting For Rotating Turbine Parts Like Blades And Hubs

Ships, mining machinery, and casting engines are examples of industrial machinery that works well. With the Paper Casting Runner, casting operations are enhanced for both big and small projects, whether the goal is to improve sand quality or mold strength throughout the molding process.

Building Trust Through Quality and Service Excellence

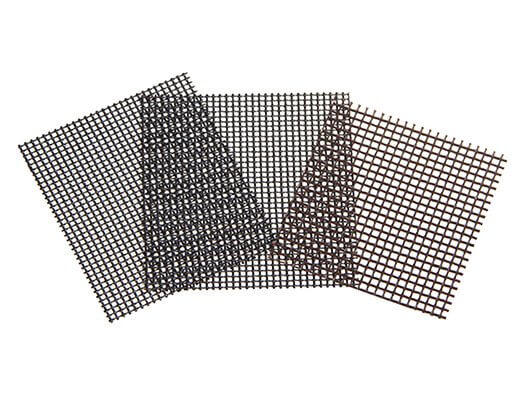

Cangzhou Sefu Ceramic New Materials Co., Ltd., is committed to delivering products of excellent quality. The Paper Casting Runner undergoes a rigorous testing process to ensure it meets the highest standards of durability and environmental responsibility. Crafted to work smoothly with direct pouring systems and high-capacity ceramic foam filters, this runner improves the filtration and casting process for our clients.

We offer customized solutions designed to meet the specific requirements of our clients, from molding technology to iron filtration and more. Our client service team is always available to assist with any inquiries, ensuring that our clients receive the support they need to optimize their casting processes.

Related Products

If you are interested in purchasing paper sprue runners or other casting materials for your Iron or Steel Casting process, contact us – our helpful team is always available to guide you through the sizing and selection process, ensuring you have the perfect refractory casting materials for your casting needs. Make SEFU your reliable supplier.

The Paper Casting Runner improves casting quality by providing better flow distribution, minimizing non-metallic inclusions, and offering superior thermal insulation, which leads to fewer casting defects and enhanced mold strength.

Absolutely. The Paper Casting Runner can be used alongside high-capacity ceramic foam filters and other gating system components to improve overall casting efficiency and filtration quality.

The Paper Casting Runner is available in a variety of sizes to meet specific casting requirements, and custom sizes can be manufactured upon request.

With its low-residue performance and minimal waste generation, the Paper Casting Runner significantly reduces the need for extensive cleanup and disposal, leading to cost savings for foundries.

The runner’s thermal insulation properties ensure a controlled cooling rate, reducing the risk of defects and improving the overall structural integrity of the cast.

Yes, the Paper Casting Runner is lightweight and portable, making it easy to integrate into existing casting processes without requiring extensive modifications.

Yes, its thermal insulation properties help to accelerate casting processes by ensuring a more consistent heat distribution, which can lead to reduced cycle times.

It should be stored in a dry, cool place away from moisture to maintain its quality and performance for extended periods.

While it is designed for single-use, the Paper Casting Runner’s durability during the casting process ensures optimal performance throughout its application.

You can contact our sales team or visit our website to request a quote or place an order for the Paper Casting Runner tailored to your specific casting needs.