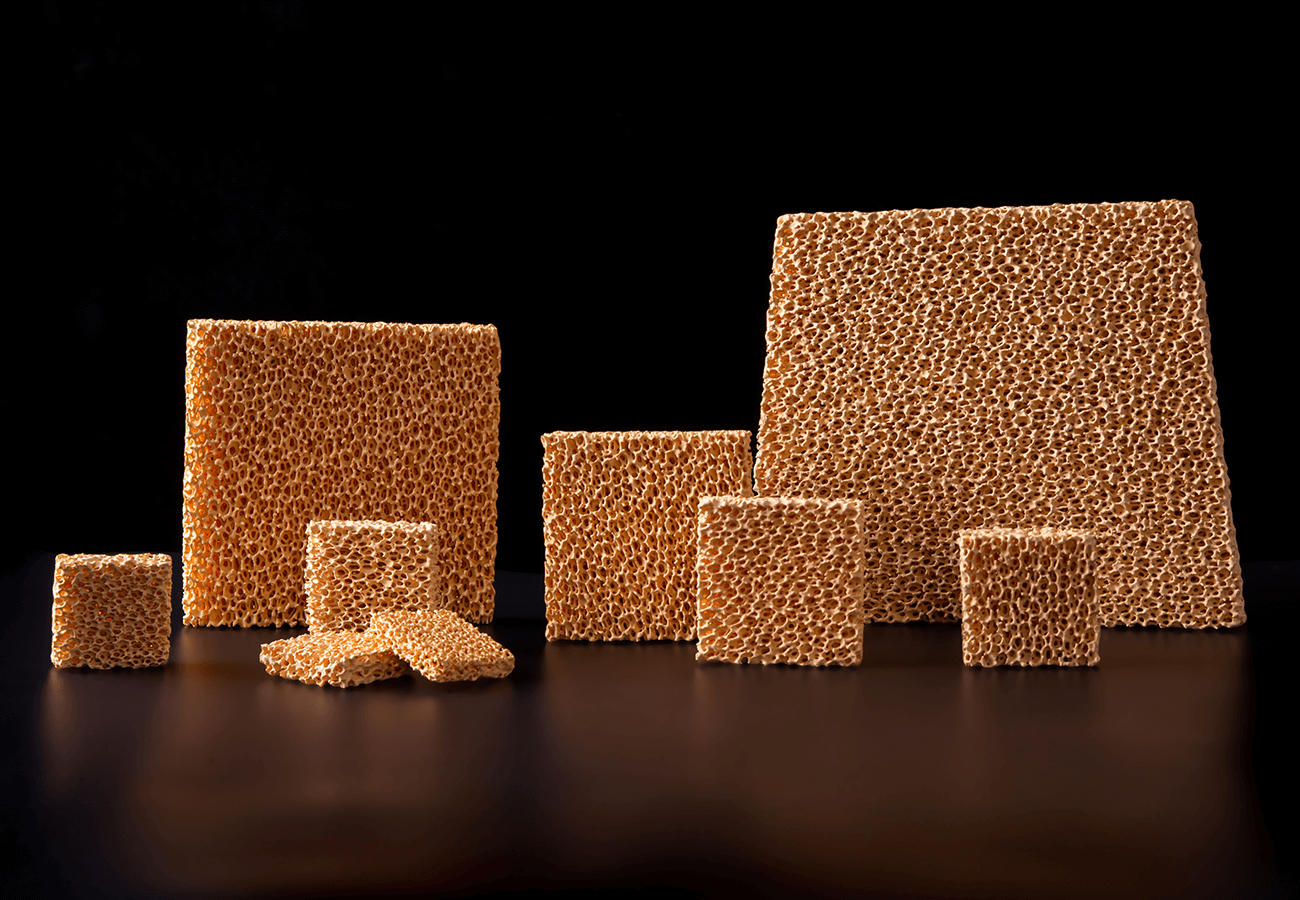

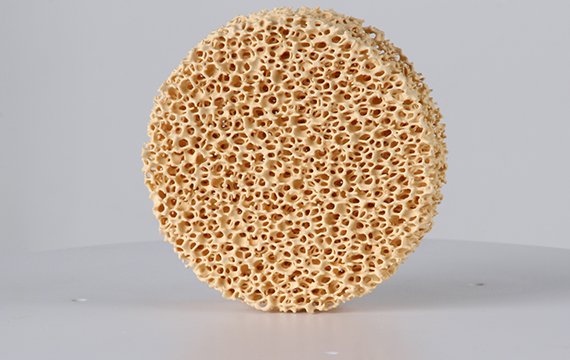

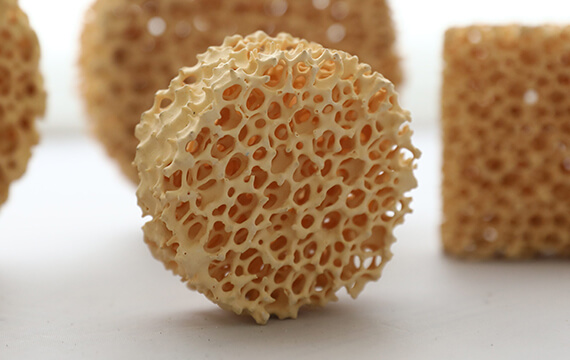

Zirconia Ceramic Foam Filters For Steels And High-Temp Alloys

ZrO₂-based foam filters are designed for high-alloy and carbon steel applications. They provide a smooth pour of molten metal, keeping slag and other inclusions out. Discover a solution for larger to smaller in-gates and cup molding, all in one place – SEFU CERAMIC.

- Remarkable filtering effect on all steel grades.

- Excellent raw materials and advanced production technology.

- Stable dimensional tolerance.

Description

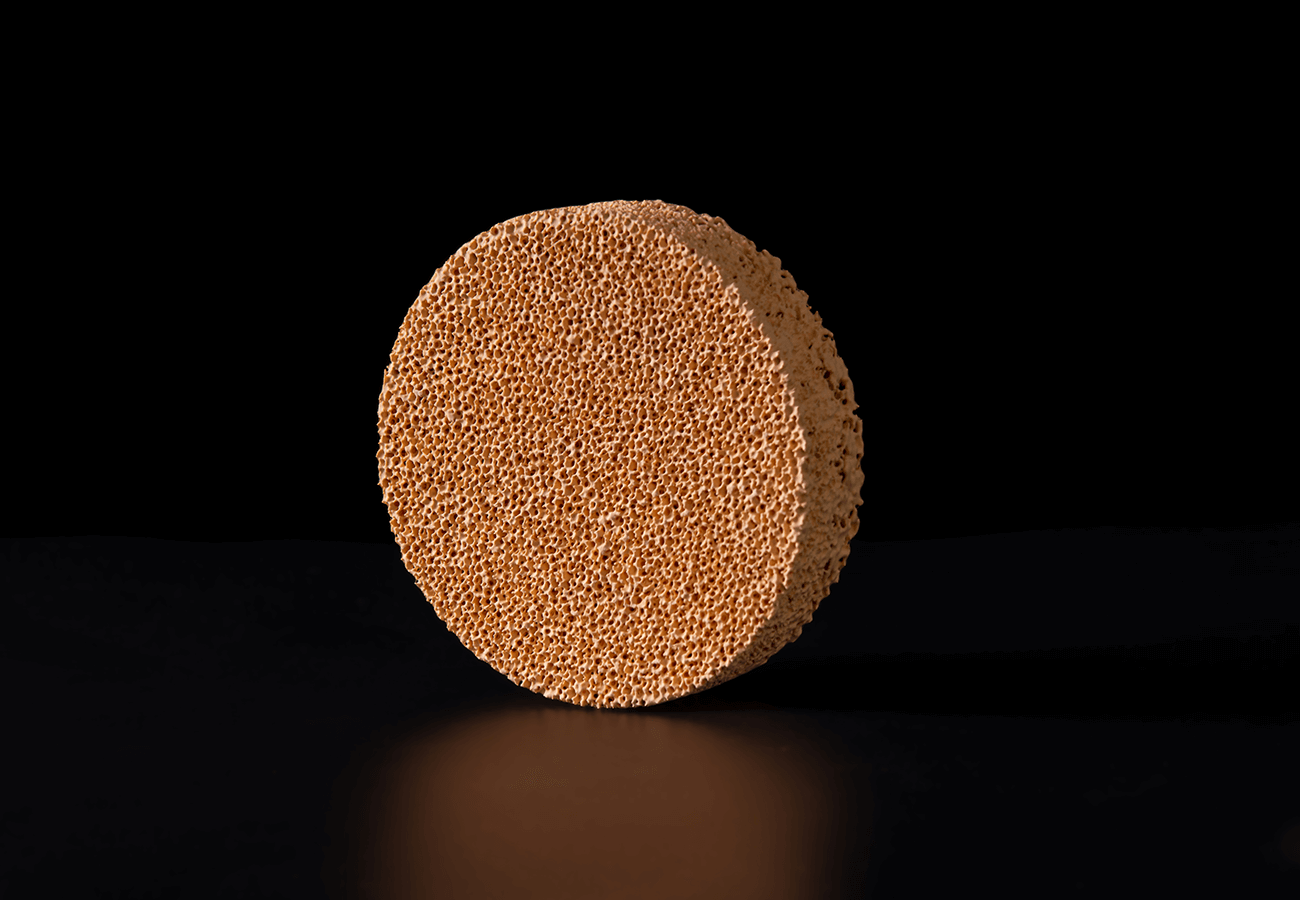

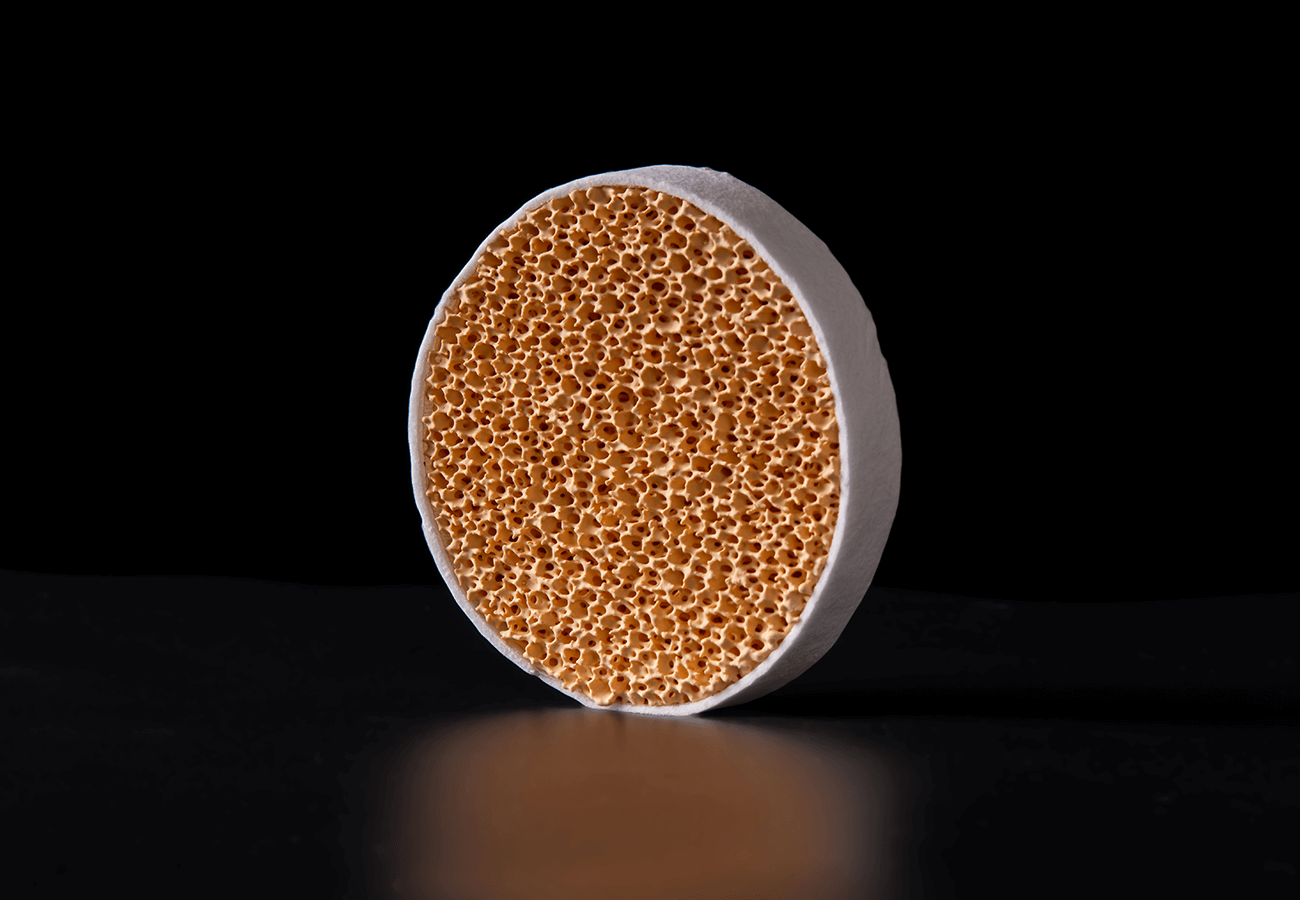

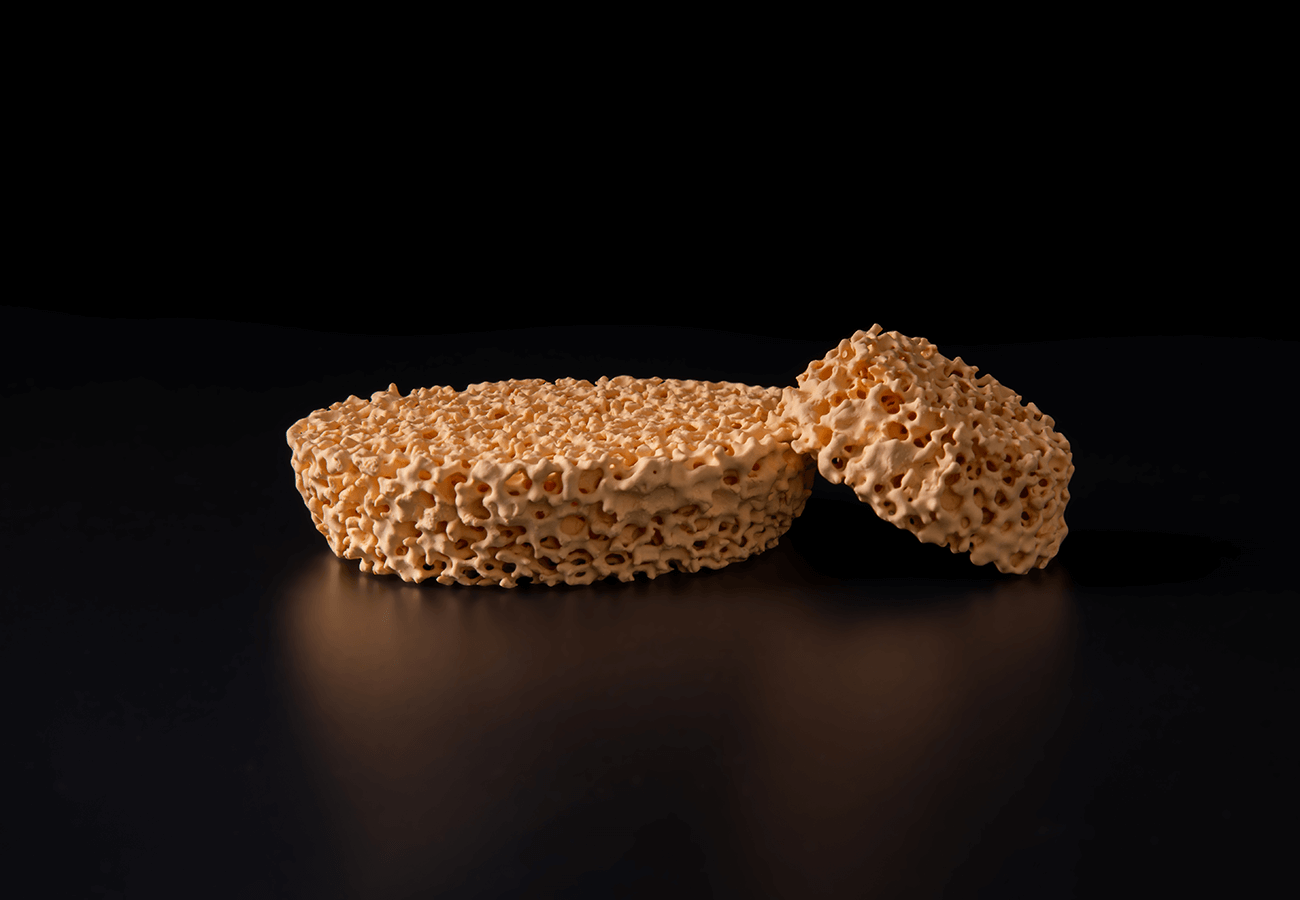

SEFU’s zirconia ceramic foam filters are highly resistant to sudden thermal shock. Their typical tolerance rate ranges up to 1700°C. Featured in yellow, it’s made from a durable composite material called ZrO₂, known for its ability to withstand high pressure without warping or breaking down.

When the molten metal passes through the porous 3D structure, its multiple cross-linked pores slow down its movement and promote even distribution by reducing the chaotic turbulent flow. Typically, it is applied in gating systems for investment casting. It’s worth mentioning that, Zr filters are pivotal in nickel-based alloys, stainless steels, and lost wax processes.

- Product Parameters

- Regular Sizes and Filtration Capacity

| Chemical Composition | ZrO2/SIO2 |

| Porosity (%) | 80~90% |

| Colour | Yellow |

| Application Temperature | Max.1700°C |

| Compression Strength (Mpa) | ≥1.2 |

| Thermal Shock Resistance | 1100°C—room temperature 6 times |

| Bulk Density | 0.8-0.9g/cm3 |

| Size (mm) |

Flow Rate (kg/s) |

Capacity (kg) |

|

| Carbon Steel | Alloyed Steel | ||

| 40×40×20 | 2 | 2.5 | 32 |

| 50×50×22 | 3 | 4 | 50 |

| 55×55×22 | 4 | 5 | 55 |

| 60×60×22 | 3 | 4 | 70 |

| 60×60×25 | 3 | 4 | 70 |

| 75×75×25 | 5 | 6.5 | 105 |

| 100×100×25 | 7 | 10 | 190 |

| 150×150×30 | 17 | 22 | 420 |

| Dia 50×22 | 2 | 3 | 40 |

| Dia 50×25 | 1.5 | 2.5 | 40 |

| Dia 60×25 | 2 | 3.5 | 50 |

| Dia 70×25 | 3 | 4.2 | 70 |

| Dia 75×25 | 4 | 5.5 | 85 |

| Dia 90×25 | 6 | 8 | 115 |

| Dia 100×25 | 7 | 9 | 145 |

| Dia 120×25 | 11 | 14 | 210 |

| Dia 150×30 | 12.5 | 15 | 330 |

Advantages of SEFU's ZrO₂-based Foam Filters

- Dimensionally precise. Easy to fit in with the casting system. It avoids excessive manpower for adjustments during installation.

- Lightweight.

- Placed both vertically and horizontally. Optimized for different metal flows and mold configurations.

- Corrosion-resistant.

Features

- Allows smooth, uniform metal flow that enhances the surface finish of the final cast product.

- Has high hot strength – remains stable at extreme temperatures (up to ≤1700 ºC).

- This 3D structure efficiently supports high-volume, high-precision casting by minimizing the risk of clogging.

- Offers higher mechanical strength, leading to fewer replacements and minimal downtime.

- Prevents exposure to oxygen, significantly reducing reoxidation.

- Simpler design pattern for a hassle-free production cycle.

Applications

- High-strength alloys – engine components and structural parts

- Corrosion-resistant stainless steel – pumps, valves, and fittings

- Precision-molded stainless steel – automotive parts

- Nickel and cobalt-based alloys

Why choose SEFU for ZrO₂- based filters

SEFU Ceramic is an ISO-certified Zirconia (Zr) filter manufacturer and a worldwide distributor. Our filters undergo a series of tests and analyses before they are wrapped and shipped. When you choose SEFU for zirconia ceramic foam filters, you are getting filters that have:

- Optimized ZrO₂-based filters: We ensure that the filters feature a balanced structure, combining both porous and denser characteristics, which allows for effective trapping of even the finest inclusions.

- Exceptional bending strength: They are built with significant bending strength to withstand considerable flexural stress.

- High porosity: Whether you’re filtering steel or high alloys, our filters provide good air permeability and precise filtration accuracy.

- Reduced wear and tear: There is a lower likelihood of causing wear and tear issues.

- Temperature resilience: Our filters are tested to ensure they handle rapid temperature changes without losing filtering capacity.

- 24/7 customer service: We provide round-the-clock support for all your needs.

- OEM service availability: Customized OEM services are also available.

Related Products

Want to buy more casting materials to improve the quality of your castings? Click below for more molten metal filtration products and other foundry materials.

FAQ Guide About Zirconia Ceramic Foam Filters

If you want to know anything else about Zirconia Ceramic Foam Filters, please contact us to leave your questions, professional foundry solutions are waiting for you.

They are particularly useful in gating system applications and can be used inside ceramic cups for investment casting.

Narrow your search based on the viscosity, temperature, type, and size of the molten metal used in the casting process. Or else, you can contact our team for assistance in choosing the best ZFF filter based on your specific application needs.

When choosing a manufacturer for zirconia foam filters (ZFF), make sure to check if the production facility is reputable and certified with quality accreditation. SEFU Ceramic has been manufacturing zirconia ceramic foam filters for over a decade, complying with ISO 9001:2015.

ZFF filters are packaged in sturdy cardboard boxes that provide excellent protection against damage. Each box contains a separate partition lined with soft tissue. Inside each pack, you’ll find the filter along with details about its porosity, production date, order number, filter type, and additional labels.