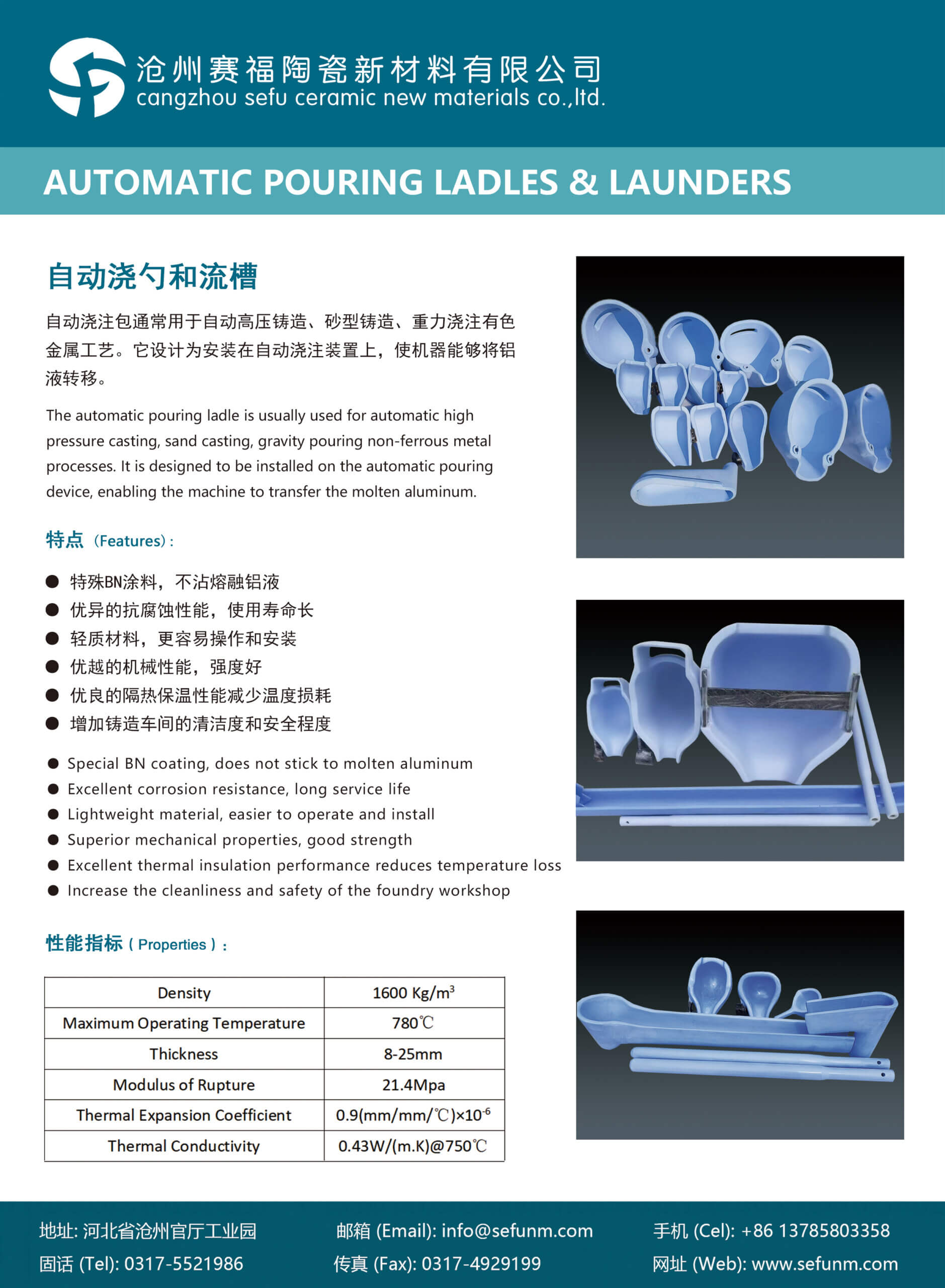

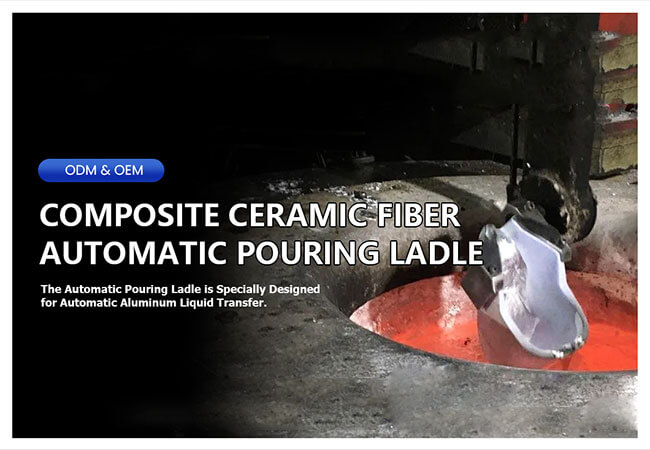

Auto Pour Ladle

SF-FOUNDRY Auto Pour Ladle for Aluminum is an automated pouring tool designed for the aluminum and aluminum alloy casting industry. It uses advanced composite materials to ensure accurate and efficient pouring during the transfer of high-temperature aluminum liquid. This product is suitable for a variety of processes such as high-pressure casting, gravity casting and sand casting.

Automatic pour ladle is a substitute for iron pouring spoon. Compared with traditional iron pouring spoon, ceramic pouring spoon made of ceramic fiber composite material is thinner and lighter than that made of ordinary refractory materials, but it is more stable, stronger, has good heat preservation and is durable.

- Technical Parameters

- SEFU Certification

| Main Ingredients

(ceramic part) |

SIO2 | 56-60% |

| CaO | 39-44% | |

| Others | 1-2% | |

| Density | 1600 Kg/m3 | |

| Maximum Operating Temperature | 780℃ | |

| Thickness | 8-25 mm | |

| Rupture Modulus | 21.4 Mpa | |

| Thermal Expansion Coefficient | 0.9 (mm/mm/℃)X10-6 | |

| Thermal Conductivity | 0.43 W/(m.K)@750℃ | |

Performance Advantages

Reinforced Composite Ceramic Substrate

The reinforced composite ceramic fiber substrate we use has excellent heat resistance and corrosion resistance. This material is not only lightweight, but also can withstand slight mechanical shocks and extend its service life.

Special Coating Design

Boron nitride (BN) coating is used on the surface of the ladle to form a dense thermal barrier layer, which effectively blocks the penetration of aluminum liquid, so that the ladle can still maintain a smooth inner wall during long-term use.

Customized Design

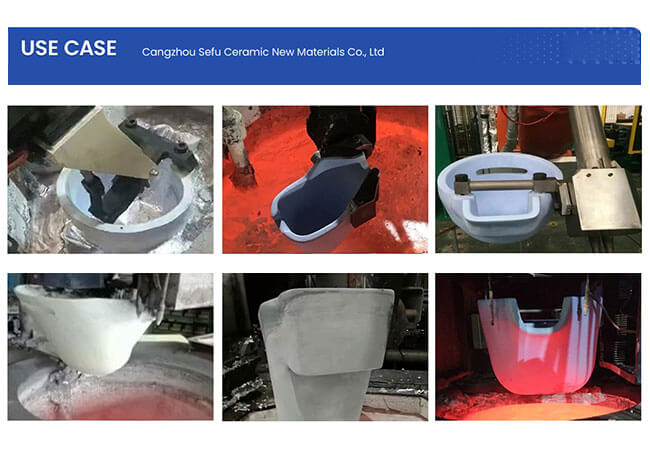

SF-FOUNDRY provides comprehensive customized services, including ladle capacity, bracket type, etc. We are committed to providing customers with solutions that meet actual needs. Whether it is robot automatic pouring or manual operation, we can provide the most suitable product design.

Customer Value

- Improve casting quality: Reduce metal inclusions, reduce porosity, and improve the overall performance of castings.

- Extend service life: Compared with traditional cast iron spoons, the service life is significantly improved and the replacement frequency is reduced.

- Optimize production efficiency: Accurate pouring, reduce waste, and improve the efficiency and stability of the overall production line.

- Cost savings: Reduce maintenance costs and reduce production losses caused by downtime for spoon replacement.

Application

SF-FOUNDRY auto pour ladles are widely used in the production of high-end castings such as aluminum alloy wheels and automotive parts. In the field of casting that pursues high precision and high efficiency, it has become a trusted choice for many companies.

- Auto parts: engine block/cylinder head, wheel hub/brake system parts, etc.

- Aerospace parts: turbine blades/brackets, cabin structure parts, etc.

- Industrial equipment parts: pump valve housing/hydraulic parts, etc.

Contact us

If you are interested in SF-FOUNDRY auto pouring ladles for aluminum, or want to know more about our products, please feel free to contact us. Our professional team will wholeheartedly provide you with technical support and customized solutions.

- Technical consultation: +86 13785803358

- Email: info@sf-foundry.com

About SF-FOUNDRY

As a professional casting material supplier, SF-FOUNDRY is always committed to providing customers with high-quality, high-performance casting solutions. With years of industry experience and technical accumulation, we have become a trusted partner of many foundry companies. Choose SF-FOUNDRY and create a brilliant future for the foundry industry!