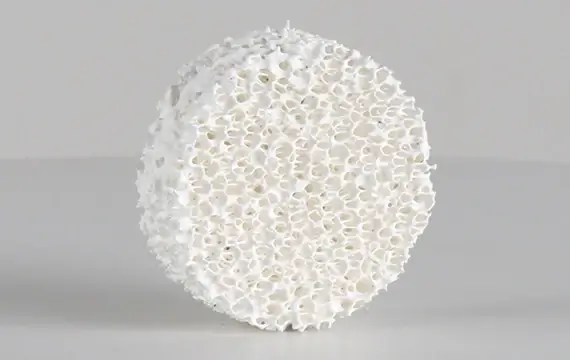

Foam Ceramic Filters: Enhancing Casting Quality with Precision Filtration

As a provider of molten metal filtration solutions, we pride ourselves on offering high-quality foam ceramic filters tailored to meet the specific foundry needs of our customers. Dive into the world of foam ceramic filters and discover how they can revolutionize your casting processes.

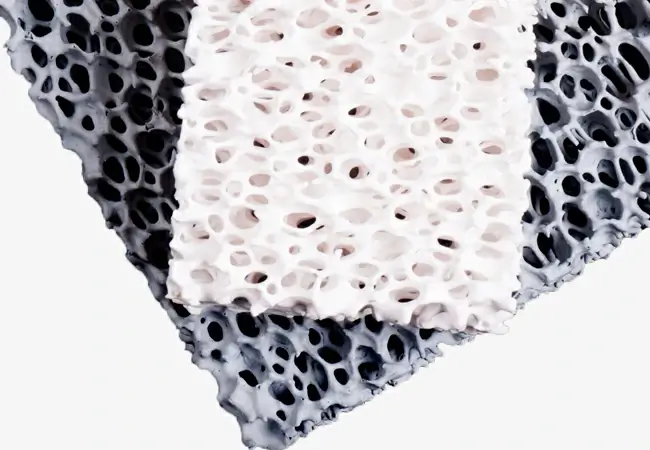

Types of Foam Ceramic Filters

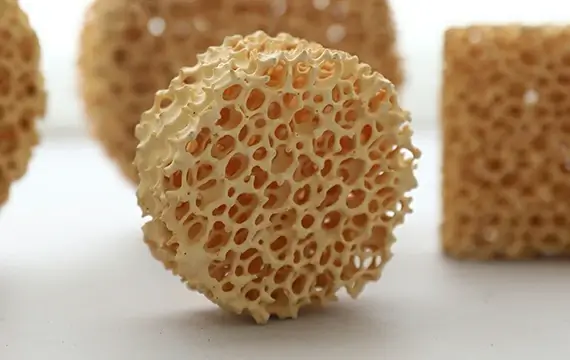

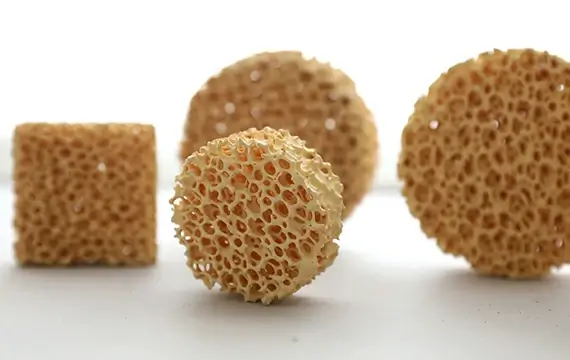

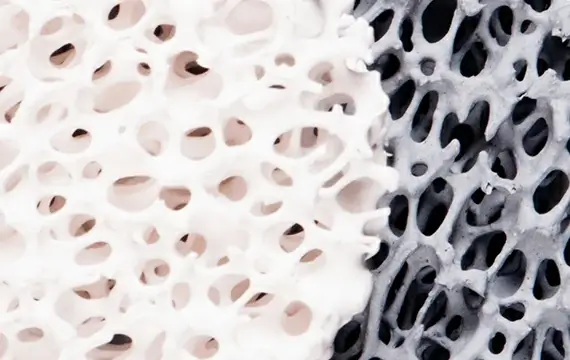

Our foam ceramic filters are crafted from high-quality ceramic materials, such as silicon carbide, alumina, and zirconia. These materials are carefully selected for their exceptional thermal stability, chemical resistance, and mechanical strength, ensuring reliable performance in the most demanding foundry environments.

- Product Parameters

| Pore Density (PPI) | 10–40 |

| Porosity (%) | 80-90 |

| Max Working Temperature (ºC) | 1000-1700 |

| Bending Strength (Mpa) | 0.8-1.0 |

| Compressive Strength (Mpa) | 1.0-1.2 |

| Thermal Shock Resistance (times/1100-0ºC) | 6 |

Applications of Foam Ceramic Filters

Foam ceramic filters are extensively used in the casting industry for filtering molten metal during the casting process.

Whether you’re casting iron, aluminum, steel, or other metals, our foam ceramic filters provide precise and efficient filtration, resulting in high-quality castings with minimal defects.

They are ideal for use in various casting methods, including sand casting, investment casting, and continuous casting.

Key Features

Superior Filtration Efficiency:

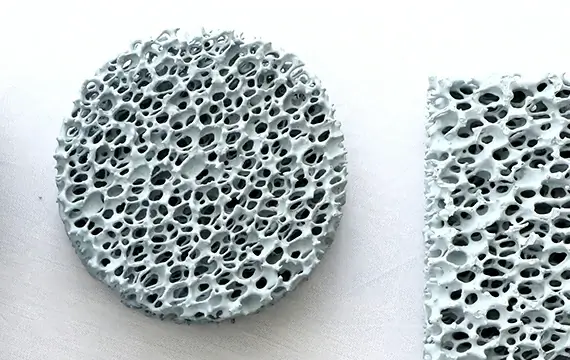

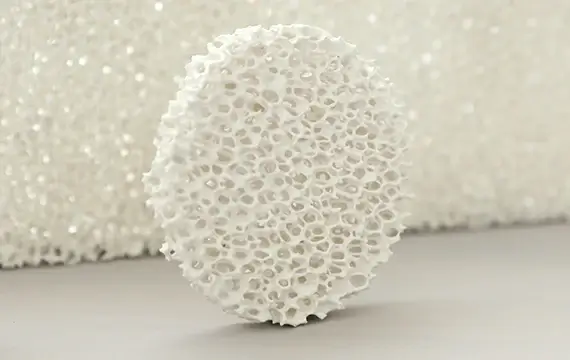

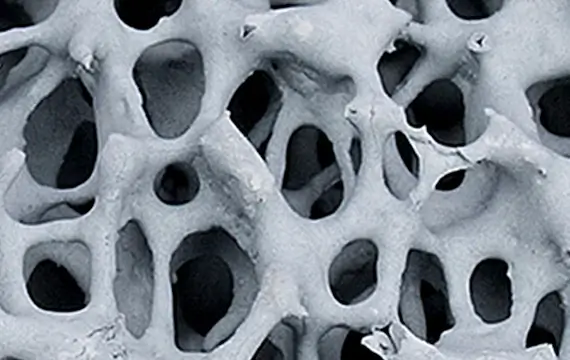

Our foam ceramic filters boast a uniform pore structure that effectively removes impurities and inclusions from molten metal, resulting in cleaner and smoother castings.

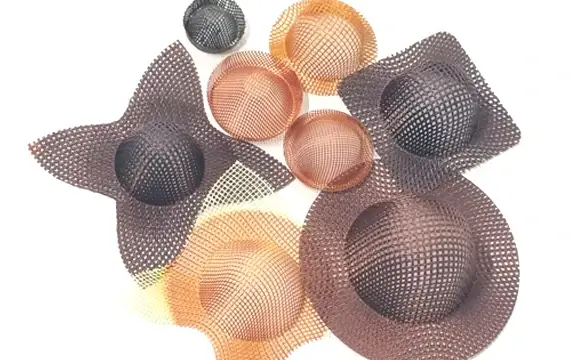

Customizable Design:

We offer foam ceramic filters in a wide range of sizes, shapes, and pore densities to suit different casting applications. Available from 10 PPI to 60 PPI. Our experienced team can also work with you to develop custom filter designs tailored to your specific requirements.

High Thermal Stability:

Withstand temperatures up to 1700°C, our foam ceramic filters maintain their integrity and filtration performance even in high-temperature casting processes.

Chemical Resistance:

Resistant to chemical reactions with molten metals, our filters ensure consistent and reliable filtration without compromising casting quality.

Related Products

Other refractory ceramic casting materials are available for use in your casting production.

Experience the Difference with Our Foam Ceramic Filters

Transform your casting processes with our premium foam ceramic filters. Contact us today to learn more about our products and how they can optimize your casting operations. Let us help you achieve superior casting quality and efficiency with our innovative filtration solutions.