Silicon Carbide Filter

Silicon Carbide Filter is not easy to be corroded by acid and alkali when filtering liquid, and will not pollute the filtered metal liquid. It can be easily processed into the required shape by changing the processing conditions.

- Through the reduction of inclusions in metal casting, iron and steel foundries get supper-grade materials.

- Available in all standards, shapes, and custom sizes according to the requirement of the foundries.

- Technical Parameters

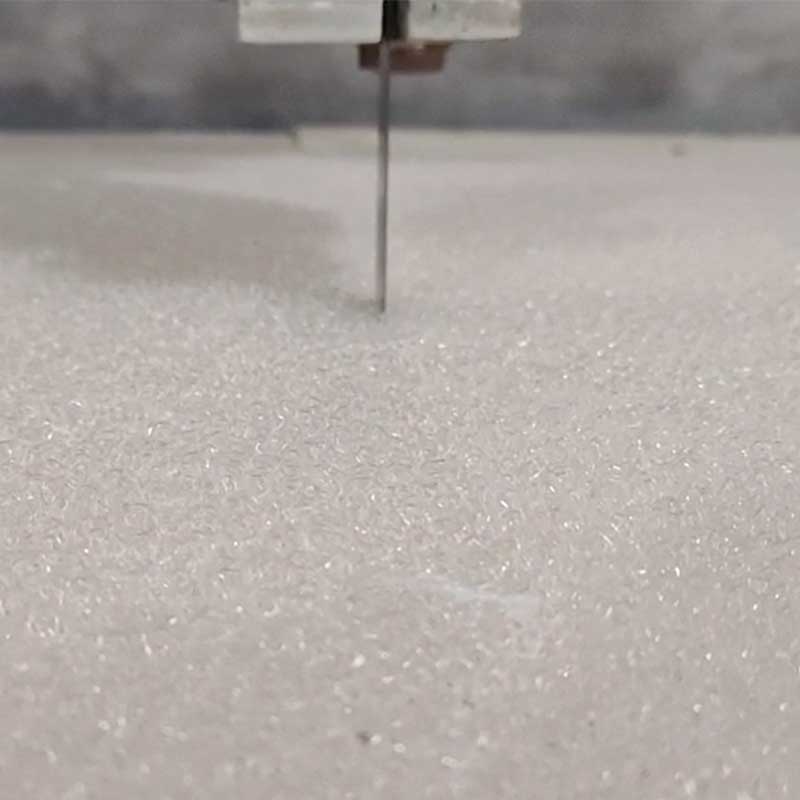

- Production of SiC Filters

| Chemical Composition | SIC/ Al2O3/SIO2 |

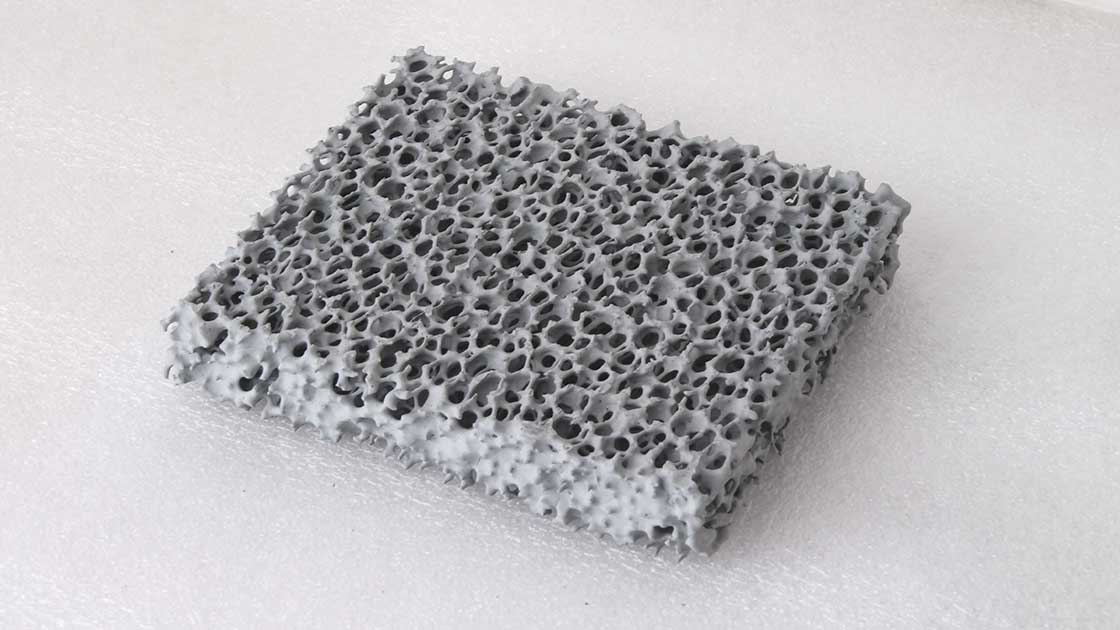

| Porosity(%) | 80~90% |

| Colour | Grey |

| Application Temperature | Max.1500°C |

| Compression Strength(Mpa) | ≥1.0 |

| Thermal Shock Resistance | 1100°C—room temperature 6 times |

| Bulk Density | 0.4-0.5g/cm3 |

| Tolerance of Dimensions | -1.5-0.5mm |

Silicon Carbide Filter Feature

SEFU Silicon Carbide Filters tend to be extremely hard, refractory, and resistant to wear, corrosion and heat, making them excellent candidates for coatings.

They often have other valuable properties in combination with toughness, such as low thermal expansion and abrasiveness.

What is Silicon Carbide Filter used for?

- Molten metal filtration in the metallurgy and foundry industry

- Exhaust gas filter carrier material for diesel and gasoline engines

- Industrial waste gas filtration, etc.

- Photocatalyst filter for air purification

- Gas distribution layer material for infrared burner

Installation Method of Silicon Carbide Filter for Foundry

- Place in the sprue cup or bottom of the sprue.

- Place it horizontally on the runner to avoid direct impact on the filter

- Placed vertically on the runner, it has the good filling ability.

- The size of the filter is determined according to its own characteristics and factors such as shape and melting.

- Try to control the casting pressure head to reduce the impact of molten metal on the filter.

- It is used in molten metal at 1560°C and should not be used over temperature.

- Avoid using filters to control casting speed.

FAQs About the Silicon Carbide Filter

As a Silicon Carbide Filters manufacturer, SEFU has a professional understanding of the use and selection of ceramic foam filters. If you need more information about sic filters, please contact us. Let our professional casting experts customize the foundry solution for you.

Silicon carbide ceramic filter uses silicon carbide ultrafine powder as the main raw material. It is a high-temperature filter with high strength, large effective filtration area and high filtration efficiency obtained after pulping, impregnation, drying, sintering, and other processes.

The PPI in the filter refers to Pores Per Inch, which is the pore density and pore uniformity of the filter. For example, 10ppi means that the uniformity of pores in any one inch length is 7~13 pores.