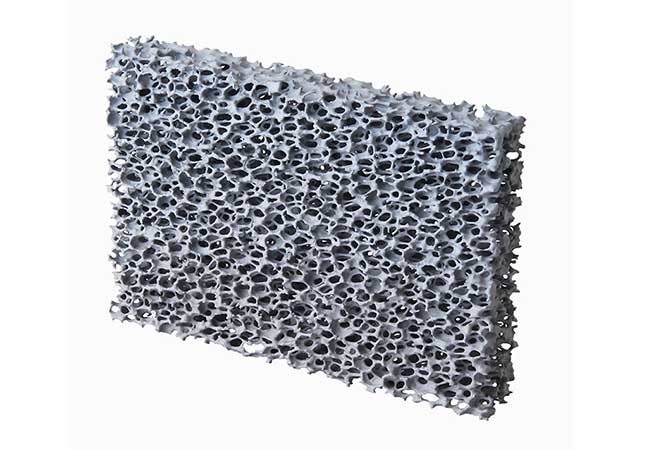

SIC Filter

SIC Filter has good molding performance and high filtering effect, which helps iron and copper foundries greatly reduce production costs. It is suitable for filtering aluminum alloy, copper alloy, gray iron, and ductile iron, especially for large wind power castings.

- High specific surface area

- High porosity

- High temperature resistant

- Chemical corrosion resistance

- Good thermal stability

- Low Density

- Technical Parameters

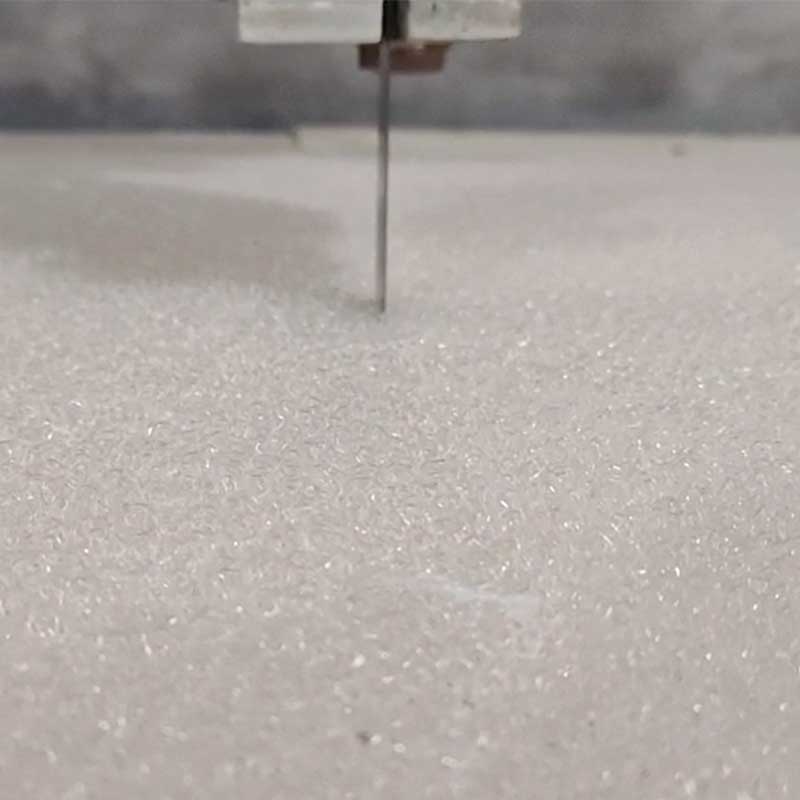

- Production of Silicon Carbide Ceramic Filters

| Chemical Composition | SIC/ Al2O3/SIO2 |

| Porosity(%) | 80~90% |

| Colour | Grey |

| Application Temperature | Max.1500°C |

| Compression Strength(Mpa) | ≥1.0 |

| Thermal Shock Resistance | 1100°C—room temperature 6 times |

| Bulk Density | 0.4-0.5g/cm3 |

| Tolerance of Dimensions | -1.5-0.5mm |

Features of Silicon Carbide Foam Filter

Silicon carbide foam are showing more and more advantages than other materials in many application fields.

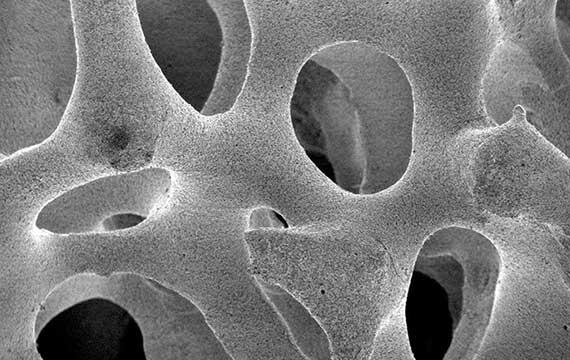

Silicon carbide foam has the advantages of high porosity, thermal conductivity, mechanical strength, oxidation resistance, corrosion resistance, etc., and its surface is uneven and has many micro-pores. This special network structure greatly increases the contact area of the two phases.

Where are silicon carbide filters needed?

It filters molten metal in the foundry industry. It is suitable for castings of iron, copper, aluminum, non-ferrous metal, and large castings.

SiC filters can meet the casting of various castings in machinery manufacturing industries such as automobiles, shipbuilding, locomotives, aviation, aerospace, machine tools, electrical appliances, engineering pipelines, valves, and pipe fittings.

What is the Function of SIC Filter?

SIC ceramic filters can effectively remove or reduce inclusions in molten metal.

It improves the purity of the metal liquid, making the surface of the cast metal casting smooth, uniform in structure, high in strength, and low in reject rate. At the same time, the machining loss is further reduced, the labor productivity is improved.

FAQs About the SiC Filter

Do you want to learn more about SiC Filter? Click below to learn more.

As a Ceramic Foundry Filters manufacturer, SEFU provides you with professional customized services and casting solutions. Leave your questions and let our professional engineers answer them for you.

Silicon carbide ceramic filter uses silicon carbide ultrafine powder as the main raw material. It is a high-temperature filter with high strength, large effective filtration area and high filtration efficiency obtained after pulping, impregnation, drying, sintering, and other processes.

Silicon carbide is mainly used in functional ceramics, advanced refractories, abrasives and metallurgical raw materials.

Due to the excellent performance of silicon carbide ceramics, the filter has the characteristics of high temperature resistance, high pressure resistance and corrosion resistance. Silicon carbide ceramic filters have excellent thermal stability, high mechanical strength and good wear resistance. It can be applied to the filtration of high-temperature and high-pressure fluids.

The PPI in the filter refers to Pores Per Inch, which is the pore density and pore uniformity of the filter. For example, 10ppi means that the uniformity of pores in any one inch length is 7~13 pores.