Ceramic Filter Foundry - Molten Metal Filtration

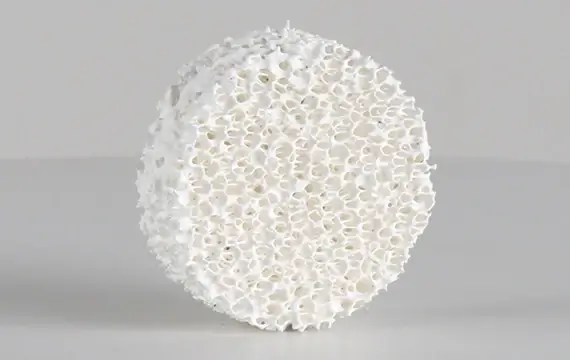

At SF-Foundry, we specialize in advanced ceramic filters designed specifically for the foundry industry. Our meticulously crafted ceramic filter foundry products deliver superior molten metal filtration capabilities, ensuring exceptional casting quality.

Materials and Working Temperatures

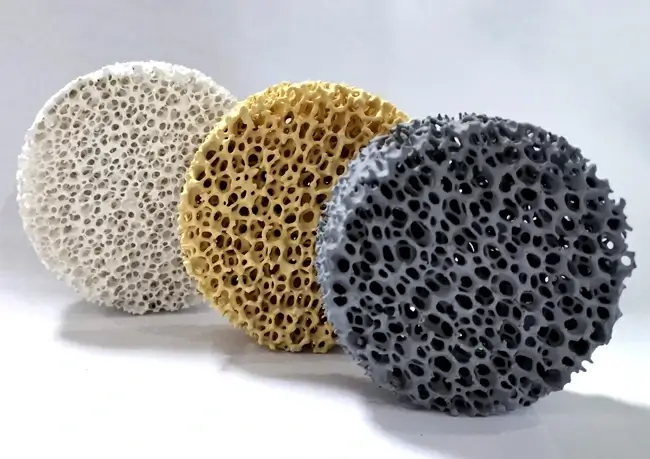

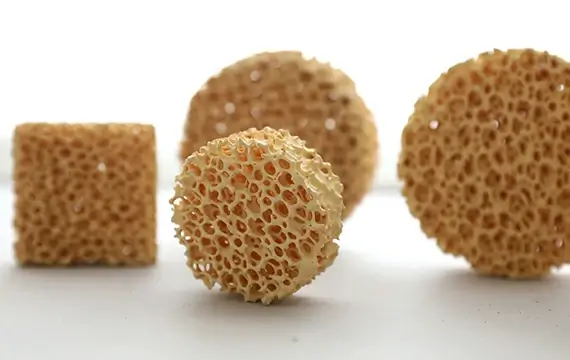

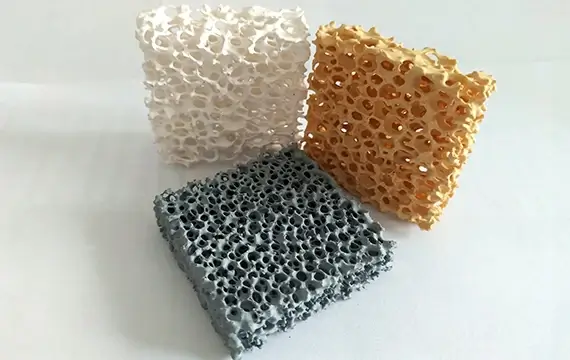

Our ceramic filter foundry products are manufactured using high-quality ceramic materials, including alumina, zirconia, and silicon carbide. These materials offer exceptional thermal stability, chemical resistance, and durability.

Ideal for filtering aluminum and aluminum alloys in industries such as aerospace and automotive, our alumina-based filters can withstand temperatures up to 1200°C (2192°F).

With superior resistance to chemical reactions, zirconia-based filters are well-suited for filtering molten steel. They can operate at temperatures up to 1700°C (3092°F) or higher.

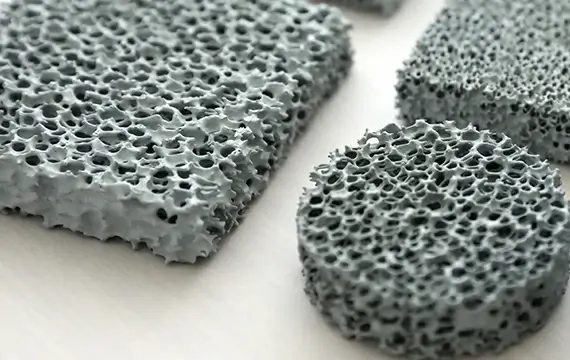

With high-temperature strength and excellent thermal conductivity, silicon carbide filters are commonly used for filtering molten iron, aluminum, and copper. They can withstand temperatures up to 1500°C (2732°F).

- Product Parameters

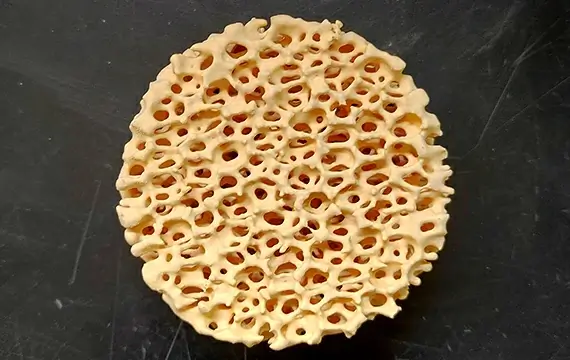

| Pore Density (PPI) | 10–40 |

| Porosity (%) | 80-90 |

| Max Working Temperature (ºC) | 1000-1700 |

| Bending Strength (Mpa) | 0.8-1.0 |

| Compressive Strength (Mpa) | 1.0-1.2 |

| Thermal Shock Resistance (times/1100-0ºC) | 6 |

Key Features of Ceramic Filter Foundry

Experience the following key features with our ceramic filters:

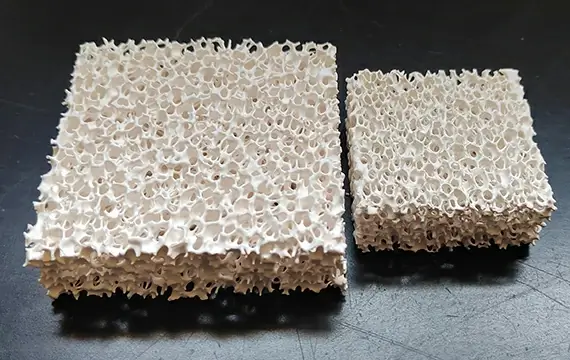

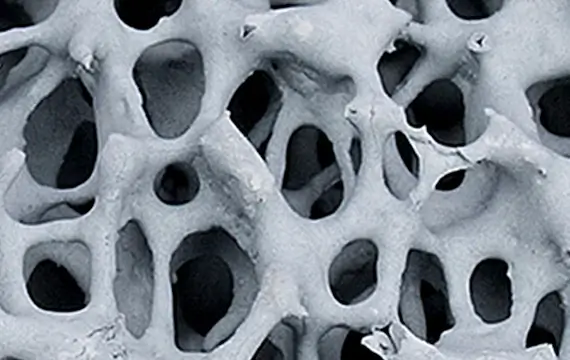

High Filtration Efficiency: Our ceramic filters are engineered with carefully designed pore structures and precise pore sizes, effectively capturing and removing impurities from molten metals during the casting process. This results in cleaner, high-quality castings with improved mechanical properties and surface finish.

Temperature Stability: Engineered to withstand high working temperatures in foundry operations, our ceramic filters utilize materials such as alumina, zirconia, and silicon carbide known for their exceptional thermal stability. This ensures reliable performance even in demanding foundry environments.

Customizable Options: We understand the unique requirements of different casting applications. Hence, our ceramic filters are available in various shapes, sizes, and pore configurations. This flexibility allows you to choose the optimal filter design matching your specific casting needs.

Applications of Ceramic Filter Foundry:

Our ceramic filters find applications in various foundry processes, including:

Aluminum Casting: Achieve cleaner and defect-free aluminum castings for industries like automotive, aerospace, and consumer goods.

Iron and Steel Casting: Improve the quality of iron and steel castings in construction, machinery, and infrastructure applications.

Non-Ferrous Metal Casting: Enhance the casting quality of non-ferrous metals such as copper, brass, and bronze across diverse industries.

Related Products

Available in a wide range of refractory ceramic casting materials for your casting production.

By choosing our ceramic filter foundry products, you can ensure efficient and reliable filtration, leading to higher-quality castings, reduced scrap rates, and overall cost savings.

Contact SF-Foundry today to explore our extensive range of ceramic filter foundry solutions tailored to your specific needs. Elevate your casting quality with our superior molten metal filtration technology.