Ceramic Filter for Molten Metal Filtration

SF-Foundry advanced ceramic filters for molten metal filtration are designed to meet the demanding requirements of modern foundries and metal casting operations.

- Superior Filtration Efficiency

- High Heat Resistance

- Consistent Performance

- Minimal Metal Loss

- Customizable Sizes and Shapes

- Product Parameters

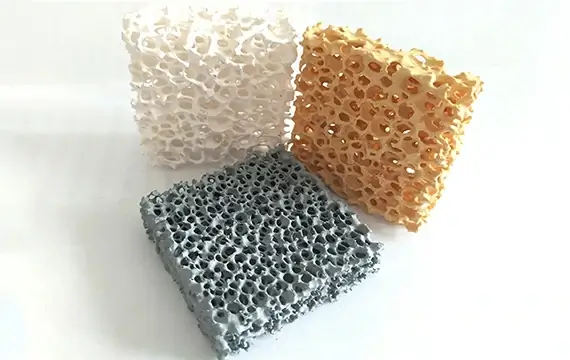

| Item | SiC Ceramic Foam Filter | Alumina Ceramic Foam Filter | Zirconia Ceramic Foam Filter |

| Color | Grey/Black | White | Yellow |

| Pore Density | 10-40 PPI | 10-40 PPI | 10-40 PPI |

| Porosity | 80%-90% | 80%-90% | 80%-90% |

| Operating Temperature | ≤1500 ℃ | ≤1100 ℃ | ≤1700 ℃ |

| Bending Strength | ≥0.8 MPa | ≥0.6 MPa | ≥1.0 MPa |

| Thermal Shock Resistance | 6 Times/1100℃ | 6 Times/1100℃ | 6 Times/1100℃ |

| Application | Ductile Iron, Gray Iron, Other Cast Iron, and Non-ferrous Alloy | Aluminum, Aluminum Alloys, and Other Non-ferrous Alloys | Stainless Steel, Carbon Steel, and Large Cast Iron |

Applications of Ceramic Filter for Molten Metal

- Aluminum casting

- Steel casting

- Iron casting

- Copper casting

- Other metal casting processes

Benefits

- Improved casting quality

- Reduced scrap and rework

- Increased productivity

- Lower production costs

- Enhanced operational efficiency

- Consistent and reliable performance

Key Features of Ceramic Filter for Molten Metal

Superior Filtration Efficiency: Our ceramic filters effectively remove impurities such as oxides, inclusions, and non-metallic particles from molten metal, resulting in cleaner and higher-quality castings.

High Heat Resistance: Engineered from specially formulated ceramic materials, these filters maintain their structural integrity even at extremely high temperatures, ensuring reliable performance in demanding foundry environments.

Consistent Performance: Each ceramic filter is manufactured to precise specifications, guaranteeing consistent and reliable filtration performance batch after batch.

Minimal Metal Loss: The porous structure of our filters allows for efficient filtration while minimizing metal loss, maximizing yield, and reducing production costs.

Customizable Sizes and Shapes: Available in various sizes and shapes, including round, square, and custom configurations, to suit the specific requirements of different casting processes.

Related Products

Customize Your Ceramic Filter for Molten Metal Now

Whether you’re casting intricate automotive components or large casting parts, our advanced ceramic filters provide the foundry filtration solutions you need for optimal metal casting results. Trust in our expertise and innovation to elevate your foundry operations to new heights of efficiency and quality.

Leave your needs and contact information in the form on the right, and our experienced experts will contact you.

You can also contact us directly via the contact details below:

- Email: info@sf-foundry.com

- WhatsApp: +8613785803358