Ceramic Casting Filters

As a manufacturer of ceramic casting filters, SF-Foundry is designed to enhance the quality and performance of your metal castings. Our advanced casting filters efficiently remove impurities and solid particles, ensuring exceptional casting results. With our commitment to advanced technology and exceptional customer service, we are your ultimate solution for casting filtration needs.

SF-Foundry: Your Trusted Manufacturer of High-Quality Ceramic Casting Filters

- Product Parameters

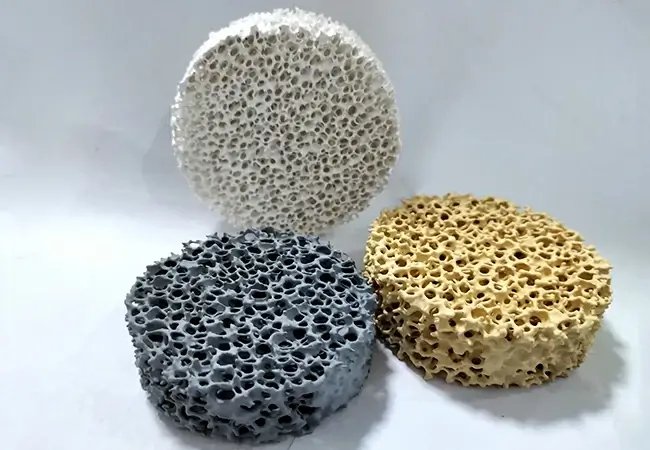

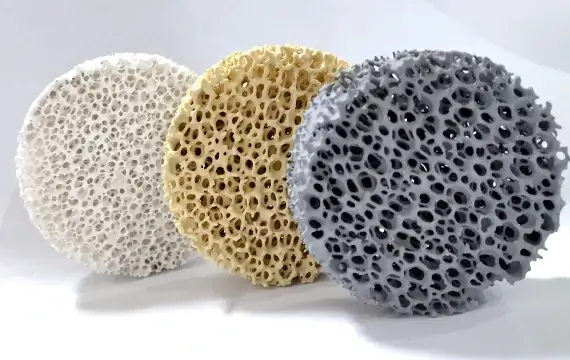

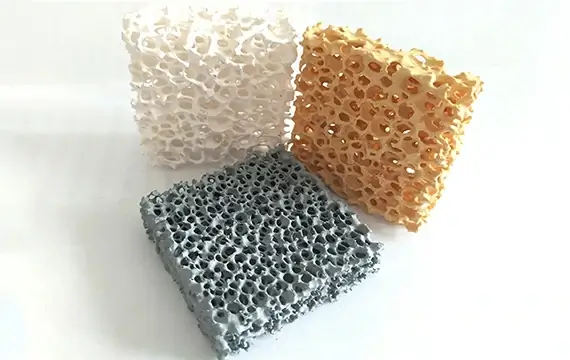

| Item | SiC Ceramic Foam Filter | Alumina Ceramic Foam Filter | Zirconia Ceramic Foam Filter |

| Color | Grey/Black | White | Yellow |

| Pore Density | 10-40 PPI | 10-40 PPI | 10-40 PPI |

| Porosity | 80%-90% | 80%-90% | 80%-90% |

| Operating Temperature | ≤1500 ℃ | ≤1100 ℃ | ≤1700 ℃ |

| Bending Strength | ≥0.8 MPa | ≥0.6 MPa | ≥1.0 MPa |

| Thermal Shock Resistance | 6 Times/1100℃ | 6 Times/1100℃ | 6 Times/1100℃ |

| Application | Ductile Iron, Gray Iron, Other Cast Iron, and Non-ferrous Alloy | Aluminum, Aluminum Alloys, and Other Non-ferrous Alloys | Stainless Steel, Carbon Steel, and Large Cast Iron |

Superior Quality and Performance

Our ceramic casting filters are meticulously crafted using premium-grade silicon carbide, alumina, and zirconia materials renowned for their exceptional heat resistance and chemical stability. This ensures the casting filters can withstand the extreme temperatures and harsh conditions encountered during metal casting operations.

By incorporating SF-Foundry’s filters into your casting process, you can expect:

- Enhanced Casting Quality: Effectively eliminate solid impurities, including inclusions, oxides, and particulate matter, resulting in castings with significantly fewer defects and superior quality.

- Superior Surface Finish: Prevent solid particles from entering the castings, minimizing surface defects and impurities, and achieving smoother and more precise surface finishes.

- Extended Mold Life: Protect molds from solid particle contamination, reducing wear and damage, and significantly extending their lifespan.

- Improved Mechanical Properties: Eliminate solid particle contamination to reduce stress concentrations and defects within castings, resulting in improved mechanical properties and consistent performance.

Key Features

- High Filtration Efficiency: Our ceramic filters feature a highly porous structure that efficiently captures and retains solid particles throughout the casting process, ensuring exceptional filtration results.

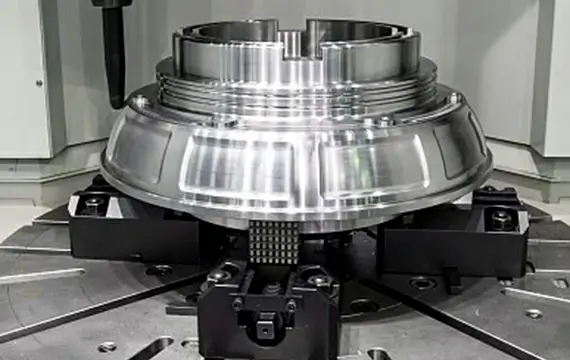

- Optimized Design: Unique filter design promotes uniform flow and distribution of molten metal, minimizing turbulence and maintaining consistent filtration performance.

- Wide Range of Sizes: Choose from our extensive selection of ceramic casting filters, available in various sizes to meet diverse casting requirements and applications.

- Easy Integration: Seamlessly integrate our filters into your existing gating systems with hassle-free installation and compatibility.

Industries We Serve

Our ceramic casting filters find applications in various industries, including:

-

- Automotive

- Aerospace

- Foundries

Related Products

Contact Us

If you’re interested in optimizing your metal casting processes with our ceramic casting filters, or if you have any inquiries, our dedicated team is ready to assist you. Contact SF-Foundry today to discuss your specific requirements and discover how our filters can elevate your casting quality and efficiency.

- Email: info@sf-foundry.com

- Call/WhatsApp: 86 137 8580 3358