SIC Foam Filter for Casting | SEFU CERAMIC

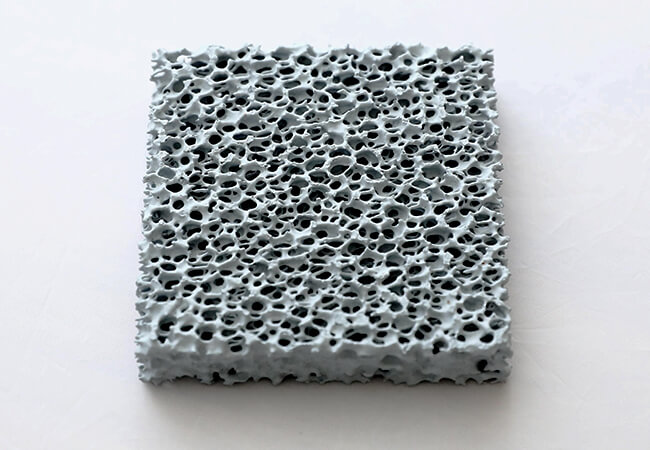

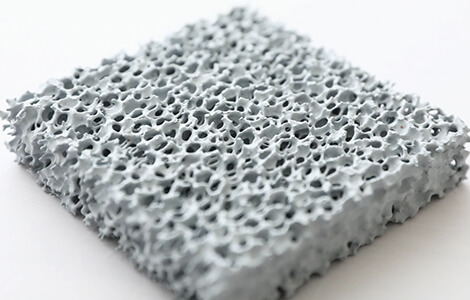

SIC foam filters, the silicon carbide ceramic foam filters, are designed to remove non-metallic inclusions and reduce turbulence in metal melts during casting. Using SIC foam filters from SEFU CERAMIC offers the following benefits:

- Removal of non-metallic inclusions from metal melts

- Reduced turbulence for consistent metal flow and fewer air bubbles

- Enhanced mechanical properties of castings

- Lower rejection rates for castings

- Reduced tool wear during machining, resulting in cost savings

Why Choose SEFU SIC Foam Filter for Casting?

Improving the quality of castings is a critical requirement for the manufacturing industry. Non-metallic inclusions in metal melts can negatively impact the final product’s mechanical properties and reduce the casting’s lifespan. At SEFU CERAMIC, we offer an ideal solution to this problem with our SIC foam filter for casting.

SEFU CERAMIC SIC foam filters are designed to remove non-metallic inclusions and reduce turbulence in metal melts during casting. The silicon carbide filters simplify the pouring system and optimize the casting yield while enhancing the quality of the castings. Our ceramic casting filters are made of high-quality materials with exceptional properties to meet the varied needs of our clients.

- Product Parameters

| Chemical Composition | SIC/ Al2O3/SIO2 |

| Porosity(%) | 80~90% |

| Application Temperature | Max.1500°C |

| Compression Strength(Mpa) | ≥1.0 |

| Thermal Shock Resistance | 1100°C—room temperature 6 times |

| Bulk Density | 0.4-0.5g/cm3 |

| Tolerance of Dimensions | -1.5-0.5mm |

SF-FOUNDRY: MOLTEN METAL FILTRATION FOR YOUR CASTING

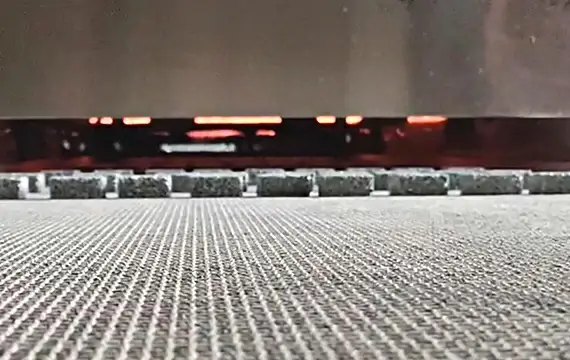

SEFU CERAMIC SIC foam filters are ideal for filtering various steel castings and large cast iron parts, high-temperature superalloys, aerospace castings, magnetic materials, copper-magnesium alloy continuous casting, low-pressure casting of non-ferrous metal alloys, and many more.

Features of SIC Foam Filter for Casting

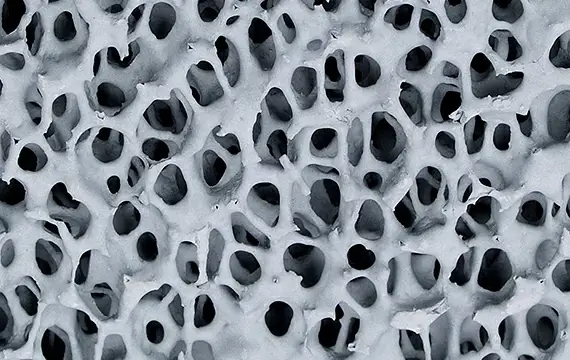

The raw materials of SIC foam filters are mainly silicon carbide and polyurethane organic sponge. SiC filters are widely used material in the casting industry due to their excellent thermal, chemical, and mechanical properties.

- SEFU casting filters have a porosity of 85% to 90%, offering excellent filtering capabilities.

- Available come in different PPI sizes (10, 15, 20, and 30) to suit different applications.

- The SiC filters can withstand temperatures of up to 1550°C, making them a reliable option for high-temperature casting.

Why Choose SEFU CERAMIC?

SEFU CERAMIC is an experienced and reliable ceramic foam filter manufacturer, including SIC foam filters, and supplies them to various industries worldwide.

Our ceramic filters cater to different casting conditions, and we offer customized solutions to meet specific requirements.

SEFU CERAMIC operates on a quality-first approach, and we have passed the ISO 9001: 2015 quality management system certification. Our mission is to assist our clients in producing high-quality castings while reducing costs and maximizing efficiency.

Related Products

SEFU team supplies you with more molten metal filtration products and other foundry materials to help you improve casting quality and save production costs.

Using SEFU CERAMIC’s SIC foam filter for casting provides a cost-effective and efficient solution to improve casting quality while reducing costs. Contact us today and experience the difference that SEFU CERAMIC can make to your casting operation!