Riser Sleeves Solve Your Casting Problems

- Manufacturer of riser sleeves for the iron, steel, and non-ferrous foundry industry.

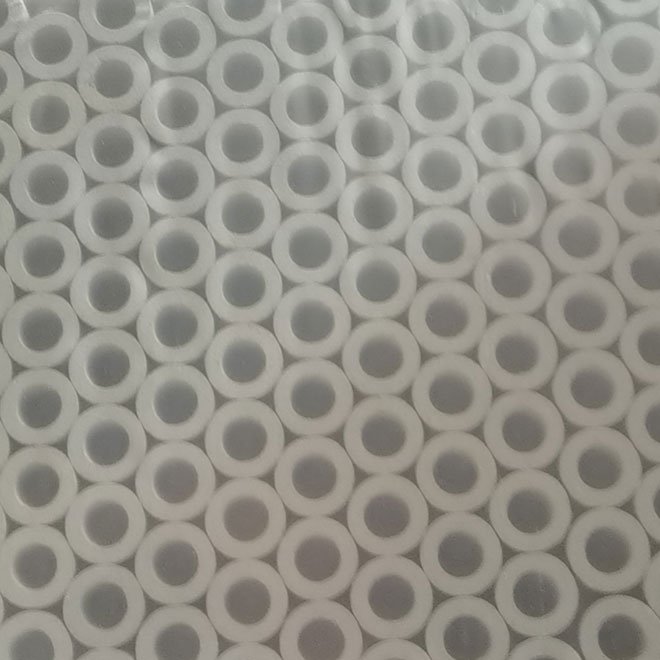

- Available in vacuum formed ceramic fiber construction.

- Types include straight, dome, round neck down, direct pour cup and breaker core insert sleeves

Cangzhou Sefu Ceramic New Materials Co., Ltd. specializes in manufacturing premium riser sleeves designed to reduce shrinkage and improve the quality of iron and steel. Our extensive expertise includes every stage of the process, from design and manufacturing to application support and rigorous quality assurance.

Riser sleeves from SEFU, which come in exothermic and blind varieties, are crucial parts of castings made of steel, alloy steel, and iron. Their method of keeping liquid metal in the riser chamber throughout cooling and solidification reduces shrinkage and guards against defects such as porosity. These sleeves guarantee the creation of premium metal castings by helping with exhaust and slag collection as well.

SEFU Riser Sleeve Types

SEFU’s Exothermic Riser Sleeves Can Help You Get Better Quality Castings

Key Features of Riser Sleeves

- Advanced Thermal Performance: Superior casting quality is ensured by Advanced Thermal Performance, which offers heating, thermal insulation, and fire resistance.

- Defect Mitigation: Provides denser, more dependable castings by successfully removing problems like as shrinkage and cavities.

- Optimized Production Efficiency: Enhanced riser feeding efficiency leads to increased casting yields and better financial results, which is known as optimized production efficiency.

- Cost-Effective Operations: Simplifies the casting process by cutting down on the time and cost needed to clean risers.

Enduring Quality & Personalized Service

Consistent Quality, Trusted Assistance

Our dedication lies in offering premium riser sleeves that satisfy the highest industry requirements. Superior materials with exceptional thermal and mechanical capabilities are used to create our casting riser sleeves, ensuring longevity and effectiveness in a variety of casting applications.

We are delighted to provide outstanding customer service, including professional advice, timely delivery, and ongoing assistance to help our clients attain the best possible outcomes from their casting operations.

Advantages of SEFU’s Riser Sleeve

Superior Density:

- High-density composition improves internal structure and lowers flaws.

- Improved internal quality increases overall casting durability.

Explosion Hardening:

- Improves the surface’s hardness, which enhances wear and tear resistance.

- Castings excel in extreme conditions with enhanced durability.

Heat Retention:

- Retains heat effectively for uniform temperature during solidification.

- Superior heat management improves mechanical properties.

Breaker Core

SEFU can supply you with the breaker core matched with the exothermic riser sleeve. It is more convenient for you to remove the feeding riser sleeve, helping you save labor and production costs.

Application

Riser Sleeves – The Key to Defect-Free and Dense Castings

Riser sleeves are essential in sand and investment casting, ensuring outstanding density and structural integrity by preventing shrinkage faults. These sleeves also aid in exhaust and slag collection, enhancing casting quality. Compatible with multiple molding techniques, including resin sand, coated sand, and lost foam, the heating riser generates and retains significant heat, making it ideal for casting a wide range of objects.

SEFU Riser Sleeves work by removing gas from the cavity, gathering inclusion-mixed molten metal, and making up for shrinkage in liquid metal. They improve overall casting performance by preserving the quality of the liquid metal, lowering flaws, and extending the solidification period.

Embedding: After molding, insert the riser sleeve into the sand mold, or construct it with the sand core first.

Activation: At about 680°C, the sleeve ignites and burns, generating heat that raises the temperature of the molten iron, increasing feeding time and streamlining operations.

Thermal insulating materials, oxidants, flux, and thermite are combined to create SEFU riser sleeves. Longevity and ideal exothermic performance are guaranteed by this combination.

Utilizing the products within two years is advised. Store the product somewhere dry and in an airtight container to maintain its integrity.

Upgrade Your Casting With SEFU’s Premium Riser Sleeves

Exothermic-insulating riser sleeve is one of the chart topping riser sleeves. It is suitable for manufacturing of medium and large iron castings and steel castings.

Insulating sleeves are used for feeding all grades of iron casting. The riser linings are made of low-density and refractory materials so as to provide insulation to the riser metal in moulds.

High Exothermic sleeve can be fixed directly on an area to target shrinkage. The product can be used as riser foremost for iron and steel castings, extending the solidification time and extending the feeding capacity of the riser.

More About Exothermic Sleeves

- Our Packaging

- SEFU RISER SLEEVE

SEFU Ceramic New Materials Co., Ltd. – pioneers in riser sleeves manufacturers provides a wide range of foundry products that are specifically made for the metal casting sector. You can rely on SEFU to provide you with unique and superior foundry solutions for a wide range of metals and alloys, molding materials, casting solutions, and environmental compliance products.

Connect with us to know us better.

- Call/WhatsApp: 8613785803358

- Email: info@sf-foundry.com

More Related Products to Help You Improve Casting Quality

FAQ About Exothermic Sleeves

High-quality refractory materials, such as ceramic fibers or exothermic compounds, are usually used to make riser sleeves, including exothermic riser sleeves and blind risers, which offer superior thermal insulation and durability.

Riser sleeves compensate for shrinkage that happens during solidification by trapping liquid metal inside the riser chamber.

They could be used with various casting procedures, such as sand casting and investment casting.

The metal remains in the liquid riser cavity for a longer period as exothermic riser sleeves generate more heat.

To make sure they fulfill industry standards, our riser sleeves go through a thorough quality control inspection process during production. Only premium materials and cutting-edge production processes are used by us to ensure reliable performance.