Porous Ceramic Filters for Casting

As a reliable manufacturer and supplier of top-quality porous ceramic filters for the casting industry, SF-Foundry specializes in providing advanced ceramic filtration solutions to enhance the integrity and quality of your castings. Our extensive product range includes:

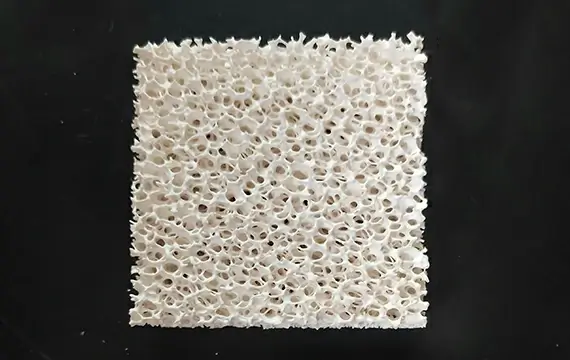

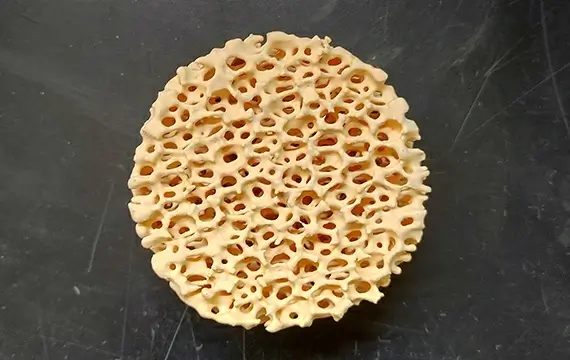

- SiC Silicon Carbide Ceramic Foam Filters

- Alumina Ceramic Foam Filters

- Zirconia Ceramic Foam Filters

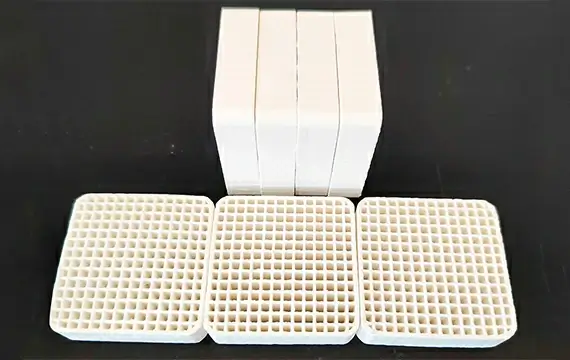

- Ceramic Honeycomb Filters

Material: Made from high-quality silicon carbide, ensuring exceptional thermal and chemical resistance.

Application: Ideal for iron, ductile iron, and non-ferrous alloy casting processes.

Features: Reticulated foam structure with open-cell porosity, allowing efficient removal of impurities like slag, sand, and dross.

Benefits: Provides excellent filtration efficiency, high-temperature stability, and improved surface finish to your castings.

Material: Crafted from premium alumina, known for its superior thermal shock resistance and chemical stability.

Application: Designed for aluminum and aluminum alloy casting processes.

Features: Three-dimensional network structure with interconnected pores for effective particle removal.

Benefits: Enhances casting integrity, reduces defects, and ensures smoother surface finish in aluminum castings.

Material: Constructed using high-strength zirconia, offering exceptional resistance to thermal shock.

Ideal for: Steel, stainless steel, and superalloy casting processes.

Features: Three-dimensional network structure with interconnected pores, facilitating efficient impurity capture.

Benefits: Elevate casting quality, minimize inclusions, and achieve superior surface finish in steel and alloy castings.

Material: Crafted with advanced ceramic materials, featuring controlled porosity.

Ideal for: Various casting processes, including ferrous and non-ferrous alloys.

Features: Honeycomb structure with uniform channels, enabling precise metal flow control and particle removal.

Benefits: Attain precise filtration, reduce turbulence, and enhance casting yield and quality.

- Product Parameters

| Item | SiC Ceramic Foam Filter | Alumina Ceramic Foam Filter | Zirconia Ceramic Foam Filter |

| Color | Grey/Black | White | Yellow |

| Pore Density | 10-40 PPI | 10-40 PPI | 10-40 PPI |

| Porosity | 80%-90% | 80%-90% | 80%-90% |

| Operating Temperature | ≤1500 ℃ | ≤1100 ℃ | ≤1700 ℃ |

| Bending Strength | ≥0.8 MPa | ≥0.6 MPa | ≥1.0 MPa |

| Thermal Shock Resistance | 6 Times/1100℃ | 6 Times/1100℃ | 6 Times/1100℃ |

| Application | Ductile Iron, Gray Iron, Other Cast Iron, and Non-ferrous Alloy | Aluminum, Aluminum Alloys, and Other Non-ferrous Alloys | Stainless Steel, Carbon Steel, and Large Cast Iron |

Related Products

Why Choose SF-Foundry?

At SF-Foundry, we prioritize product excellence and customer satisfaction. Our porous ceramic filters are meticulously manufactured using cutting-edge techniques, guaranteeing consistent performance and unwavering reliability. We offer a comprehensive range of sizes and configurations tailored to meet your specific casting requirements.

Experience the transformative impact of our porous ceramic filters on your casting process. Contact us today to discuss your filtration needs and leverage our expertise in delivering superior ceramic filtration solutions.