Ceramic Foundry Filters for Metal Casting

At SF-Foundry, we specialize in providing high-quality ceramic foundry filters that are meticulously crafted to enhance your metal casting operations. Our ceramic filters are designed to optimize the casting process, delivering cleaner castings with improved quality and reduced defects. With our expertise and dedication to quality, you can trust our ceramic foundry filters for exceptional performance and reliability.

- Product Parameters

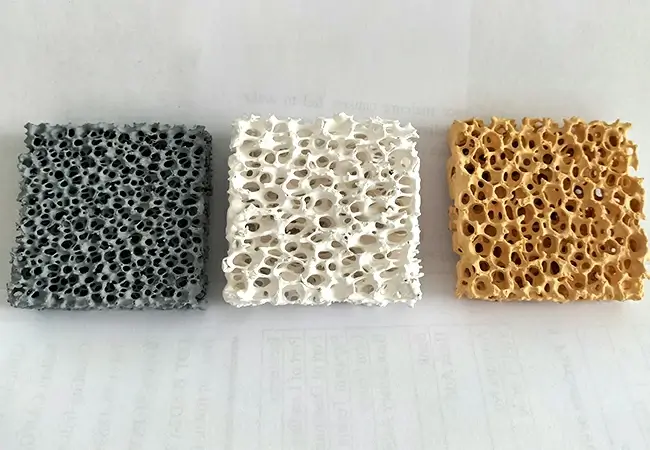

| Item | SiC Ceramic Foam Filter | Alumina Ceramic Foam Filter | Zirconia Ceramic Foam Filter |

| Color | Grey/Black | White | Yellow |

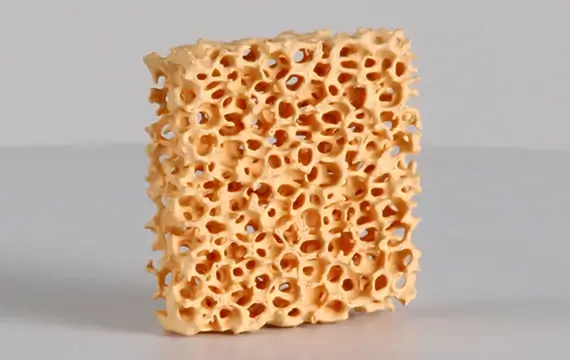

| Pore Density | 10-40 PPI | 10-40 PPI | 10-40 PPI |

| Porosity | 80%-90% | 80%-90% | 80%-90% |

| Operating Temperature | ≤1500 ℃ | ≤1100 ℃ | ≤1700 ℃ |

| Bending Strength | ≥0.8 MPa | ≥0.6 MPa | ≥1.0 MPa |

| Thermal Shock Resistance | 6 Times/1100℃ | 6 Times/1100℃ | 6 Times/1100℃ |

| Application | Ductile Iron, Gray Iron, Other Cast Iron, and Non-ferrous Alloy | Aluminum, Aluminum Alloys, and Other Non-ferrous Alloys | Stainless Steel, Carbon Steel, and Large Cast Iron |

Features of Ceramic Foundry Filters

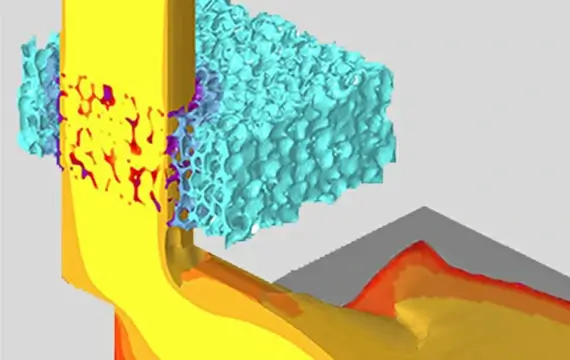

Superior Filtration: Our ceramic foundry filters are engineered to effectively remove impurities, such as slag, sand, and inclusions, from the molten metal, ensuring cleaner and higher-quality castings.

Enhanced Casting Quality: By reducing impurities, our filters help minimize defects in castings, resulting in improved surface finish, dimensional accuracy, and mechanical properties of the final products.

Ceramic Foundry Filters Uses

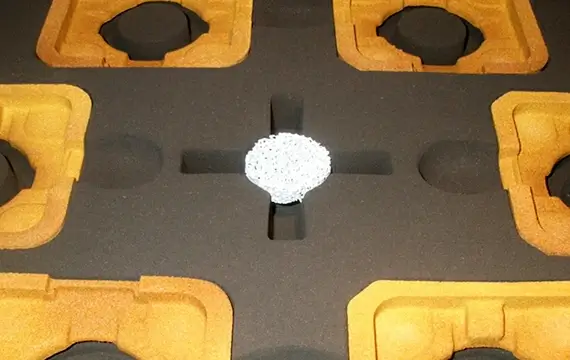

Ceramic foundry filters are compatible with a wide range of casting processes, including investment casting, sand casting, and continuous casting, making them suitable for various metal alloys and applications.

Why Choose Our Ceramic Foundry Filters?

- Advanced Ceramic Material: Crafted from high-quality ceramic materials, our filters are highly durable and can withstand the demanding conditions of the casting process, providing long-lasting performance.

- Precise Pore Sizes: With a range of pore sizes available, our filters allow for precise control over the filtration process, ensuring optimal flow rates and efficient removal of specific impurities.

- Quality Certification: Our ceramic foundry filters meet ISO 9001: 2015 standards and are manufactured under strict quality control processes, giving you peace of mind and confidence in their performance.

- Customization Options: We understand that different casting applications have unique requirements. That’s why we offer customization options, including various shapes, sizes, and configurations, to tailor our filters to your specific needs.

Related Products

How to Order

To experience the benefits of our high-quality ceramic foundry filters, simply request a quote via the content on the right or get in touch with our sales team. We’ll be happy to assist you in selecting the right filters for your casting processes and provide any additional information or support you may need.

Invest in our ceramic foundry filters and elevate your metal casting operations to new heights of quality and efficiency. Request a quote today and discover the difference our filters can make in achieving cleaner, higher-quality castings.

Email: info@sf-foundry.com

Tel/WhatsApp: +86 13785803358