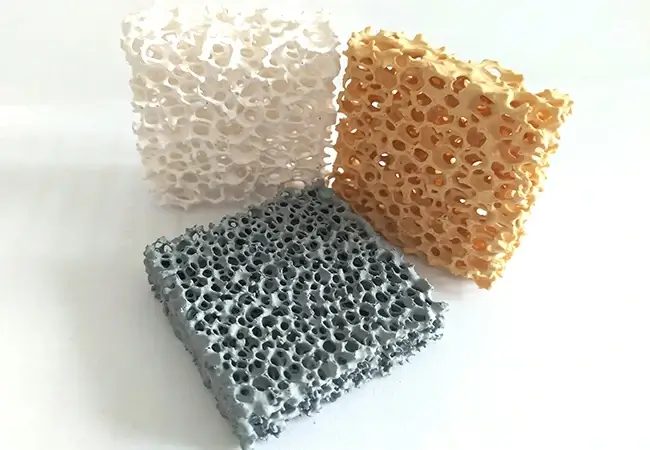

Ceramic Filter for Foundry

SEFU ceramic filters for foundry applications are meticulously engineered to enhance the quality of molten metal casting processes. Crafted from high-grade materials and designed with precision, these filters play a pivotal role in ensuring the production of superior quality castings by effectively removing impurities and contaminants from the molten metal stream.

Key Features

High Thermal Stability: Our ceramic filters exhibit exceptional thermal stability, enabling them to withstand the extreme temperatures encountered in foundry operations without compromising performance.

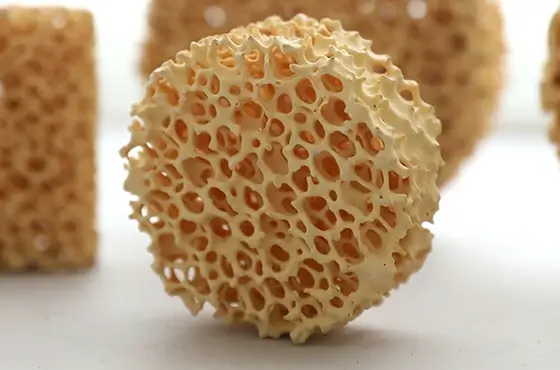

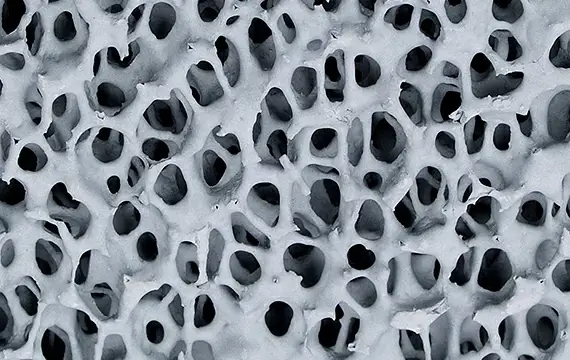

Uniform Pore Structure: Engineered with a uniform pore structure, these filters facilitate consistent metal flow while efficiently capturing impurities, ensuring uniform casting quality.

Chemical Inertness: Resistant to chemical reactions with molten metals, our ceramic filters maintain their integrity, prolonging their service life and contributing to cost-effectiveness.

Optimized Filtration Efficiency: The precisely engineered filtration media ensures high efficiency in removing inclusions, oxides, and other unwanted impurities, resulting in cleaner metal melts and superior castings.

Customizable Designs: Available in various shapes, sizes, and configurations, our ceramic filters can be tailored to meet the specific requirements of different foundry processes and casting applications.

Benefits

Improved Casting Quality: By effectively removing impurities, our ceramic filters contribute to the production of high-quality castings with enhanced mechanical properties and surface finish.

Increased Productivity: Reduced rework and scrap rates due to improved casting quality lead to higher productivity and cost savings for foundries.

Enhanced Process Control: Consistent filtration performance ensures greater control over casting processes, resulting in fewer defects and better overall process reliability.

Applications

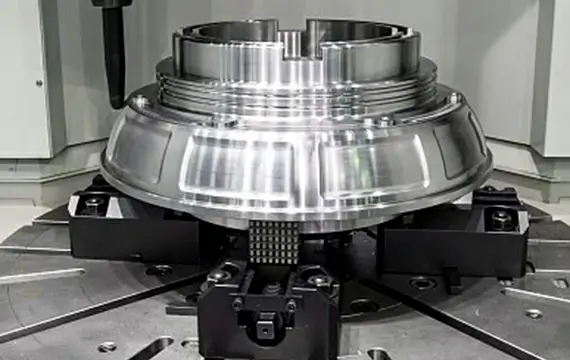

Gray Iron Casting

Ductile Iron Casting

Steel Casting

Aluminum Casting

Other Non-Ferrous Metal Casting Processes

Why Choose Our Ceramic Filters?

Quality Assurance: Manufactured to the highest standards, our ceramic filters undergo rigorous quality control measures to ensure reliability and consistency.

Technical Expertise: Backed by a team of experienced engineers and metallurgists, we provide comprehensive technical support and assistance to optimize filter selection and usage.

Customer Satisfaction: We are committed to delivering value to our customers through superior products, technical expertise, and responsive customer service.

Related Products

Contact Us

For inquiries, technical assistance, or to request a quote, please contact our sales team at info@sf-foundry.com or call +86 13785803358. We look forward to serving your foundry filtration needs.