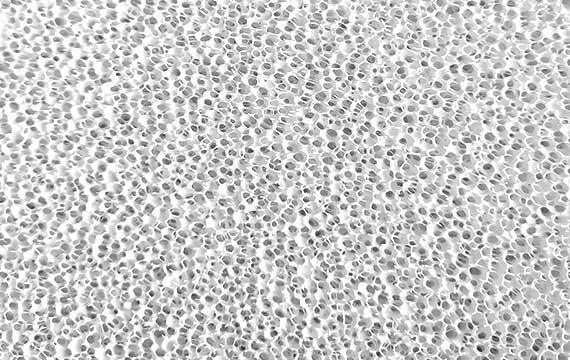

Aluminum Ceramic Foam Filter

SEFU Aluminum Ceramic Foam Filter removes the solid inclusions in the molten metal, the aluminum alloy can be smoothly forged and processed to obtain superior aluminum products.

- Superior dimensional tolerances.

- Stable chemical property.

- Excellent filtration efficiency.

- Excellent mechanical strength.

- Resistant to corrosion and thermal shock resistance.

- Beveled edges and compressible gasket.

Liquid Aluminum Filtration

Molten aluminum in a melting furnace before further processing – casting into ingots or castings – almost always requires filtration. Filtration methods depend on the casting technology used or the method of processing aluminum melt. Generally considered, it is possible and beneficial only when working with large enough volumes of metal.

Filters can be used for large industries and in small foundries, including for filtering metal during the casting of each individual cast.

- Technical Parameters

- Product Specifications

- Filter Capacity

| Porosity (%) | 80~90% |

| Working Temperature | ≤1100°C |

| Bending Strength (Mpa) | 0.6 |

| Compression Strength (Mpa) | 0.8 |

| Thermal Shock Resistance | 1100°C—room temperature 6 times |

| Volume Density | 0.35-0.45 g/cm3 |

| Dimension (inch) | Dimension (mm) | Pore Size (PPI) |

| 23*23*2 | 584*584*50 | 20/30/40/50 |

| 20*20*2 | 508*508*50 | 20/30/40/50 |

| 17*17*2 | 432*432*50 | 20/30/40/50 |

| 15*15*2 | 381*381*50 | 20/30/40/50 |

| 12*12*2 | 305*305*50 | 20/30/40/50 |

| 9*9*2 | 228*228*50 | 20/30/40/50 |

| Specification (mm) | Filter Flow Range (kg/min) | Total Filtration (T) |

| 7 inches (178*178*50) | 25-50 | 3 |

| 10 inches (254*254*50) | 45-100 | 7 |

| 12 inches (305*305*50) | 90-170 | 15 |

| 15 inches (381*381*50) | 147-280 | 20 |

| 17 inches (432*432*50) | 193-367 | 25 |

| 20 inches (508*508*50) | 274-521 | 30 |

| 23 inches (584*584*50) | 369-700 | 35 |

Multiple Options

Available from 10ppi coarse pore to 70ppi very fine pore. There will always be a product standard that suits your requirements. Ordinary sizes and special sizes required by customers can meet the requirements.

SEFU Aluminum Ceramic Foam Filter Function

It has good high-temperature stability in the molten aluminum alloy, does not contaminate alloy, and possesses good filtering and adsorption efficiency for removing oxide impurity and flux impurities from molten metal, so that it can obtain obvious filtering and purification effect.

SEFU Aluminum Ceramic Foam Filter Features

- Available in all common sizes.

- High porosity and good compressive strength.

- Ensure high-efficiency filtration.

- Low bulk density

- Good thermal shock resistance

- Corrosion resistance to molten metal

Related Products

SEFU manufactures and supplies more products for foundry and metallurgy. Make SEFU your reliable supplier.

FAQ About the Aluminum Ceramic Foam Filter

Are you still confused about aluminum ceramic foam filters? Find out more about aluminum filtration in the FAQ part.

If you are choosing a reliable manufacturer, let SEFU CERAMIC be your first choice.

Alumina ceramic foam filters can authorize great to have the suitable components for topmost efficiency in the foundry and metallurgical industry. It can be increasing casting flexibility with easy alloy changes and reduce scrap related to inclusions.

Alumina ceramic foam filter is mainly applied to the aluminum and aluminum alloy fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting, also applied to other non-ferrous metal precision casting.

The use of the filtration process is mainly based on the following considerations. On the one hand, the filtration makes the flow of molten aluminum orderly and relatively calm, and on the other hand, the solid slag in the molten metal is effectively removed, and the quality of castings is rapidly improved.

Aluminum liquid often contains impurities and inclusions. Whether the aluminum liquid is handled well or not will directly affect the quality of the cast rod. In order to effectively remove the impurities in the molten aluminum, a ceramic foam filter is used as the medium for filtering the molten aluminum.

The process of impregnating the polyurethane sponge carrier with slurry, extruding to obtain blank material, drying and sintering so as to obtain the alumina ceramic foam filter.