Zirconia Foam - Ceramic Filter for Foundry

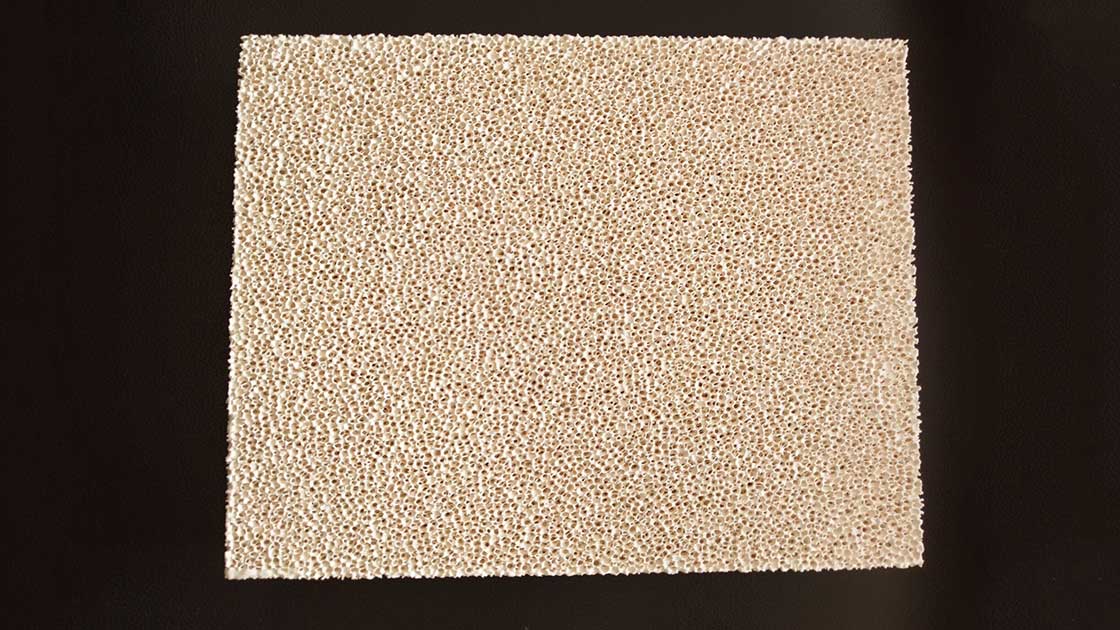

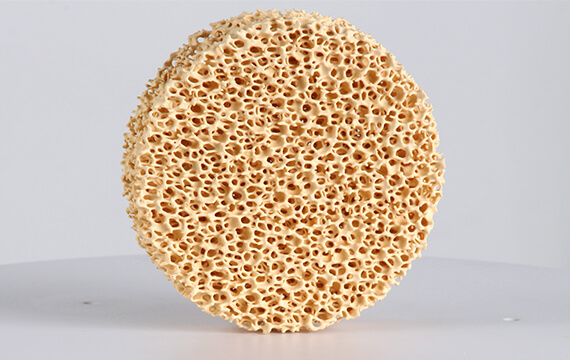

Zirconia foam, the ZrO2 ceramic foam filter, is a type of porous material with interconnected pores, known for its high-temperature resistance and excellent filtration properties. It is commonly used in metallurgical industries for purifying molten metals and alloys, such as cast iron, steel, copper, and other alloys. The porous ceramic filter is characterized by the following:

- High Porosity

- Large Surface Area

- Robust Mechanical Strength

- Thermal Shock Resistance

- Chemical Corrosion Resistance

- Filtration and Adsorption Properties

- Technical Parameters

| Chemical Composition | ZrO2/SiO2 |

| Porosity (%) | 80~90% |

| Color | Yellow |

| Application Temperature | ≥ 1700°C |

| Compression Strength (Mpa) | ≥1.2 |

| Thermal Shock Resistance | 1100°C—room temperature 6 times |

| Bulk Density | 0.8-0.9g/cm3 |

What is Zirconia Foam?

SEFU zirconia foam filter is a highly refractory casting material and can withstand temperatures of up to 1700°C, making it an ideal choice for filtering high-temperature metal alloys, including stainless steel, carbon steel, and large cast iron.

The molten metal filter is widely used in the manufacturing of automotive parts, aerospace components, machinery parts, and other high-temperature precise casting applications.

Features of Zirconia Foam Ceramic Filters

- High Porosity: It allows for the efficient filtration of molten metal and removes impurities, resulting in high-quality metal products.

- Large Surface Area: It provides a vast amount of area for metal to flow through, ensuring that metal is distributed evenly and reducing the risk of turbulence.

- Thermal Shock Resistance: It can withstand extreme thermal shocks, which occur during filtering, reducing breakage and ensuring durability.

- Chemical Resistance: Zirconia foam filters can withstand contact with chemicals and molten metal.

- Excellent Mechanical Strength: Zirconia filters are durable and have excellent mechanical strength.

- Filtration and Adsorption Properties: It removes impurities and enhances the quality of metal products.

What is zirconia foam used for?

Zirconia foam ceramic filters are widely used in the filtration of molten metal and are essential in the production of high-quality metal products. These filters are commonly used in the following applications:

Automobile Industry: Zirconia foam ceramic filters are used in the manufacturing of high-performance automotive parts, aerospace components and are also used to improve the quality of cast iron and steel parts.

Steel and Iron Industry: These filters are used in the manufacturing of steel and iron products to remove impurities and improve the quality of the final product.

Foundry Industry: Zirconia foam ceramic filters are used in the production of cast iron, aluminum, copper, and other metal alloys to remove impurities and improve the quality of the final product.

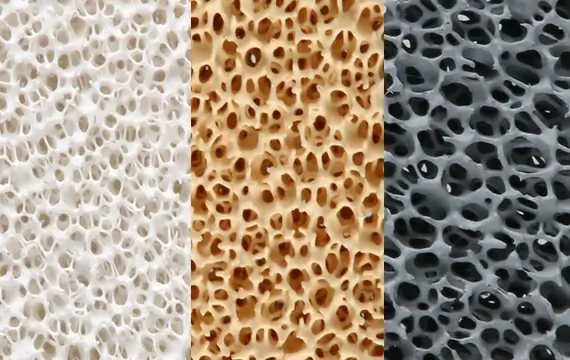

TYPES OF SEFU CERAMIC FOAM FILTERS

SEFU CERAMIC offers a wide range of ceramic filters, including zirconia foam, aluminum oxide, silicon carbide, and magnesium oxide, each designed for specific applications.

Silicon carbide filter has a maximum working temperature of 1500°C and is ideal for filtering molten iron, non-ferrous metals, and alloys.

Aluminum casting filter has a maximum working temperature of 1000°C, making it suitable for filtering aluminum and its alloys.

For more information on zirconia foam ceramic filters and other refractory casting material products, please contact SEFU CERAMIC experts and specify your requirements. SEFU CERAMIC team will be happy to assist you and provide the best product that fits your application.