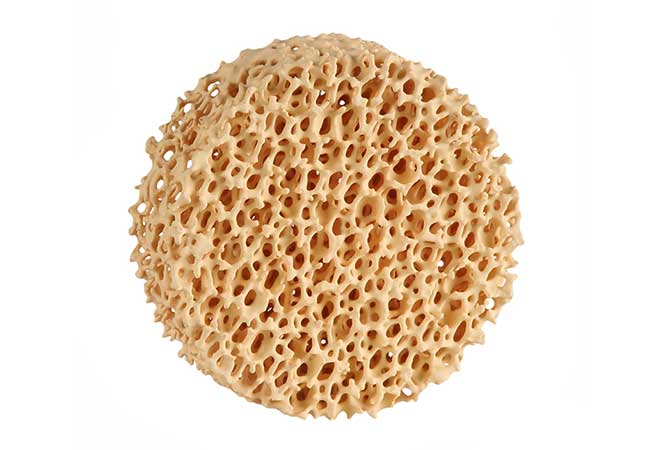

Zirconia Filter

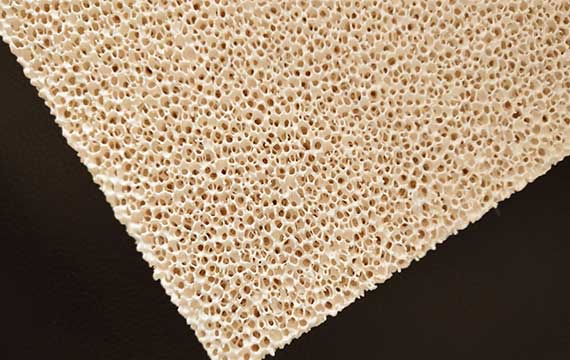

SEFU zirconia filters filter solid slag such as metal oxides contained in molten metal during the casting process. It improves the quality and yield of steel castings. It promotes technological progress in the foundry industry.

- Adjust the metal flow velocity through rectification to reduce secondary inclusions and pores.

- Reduce inclusions casting, and reduce casting scrap rate.

- Improve the surface quality and the mechanical properties of castings.

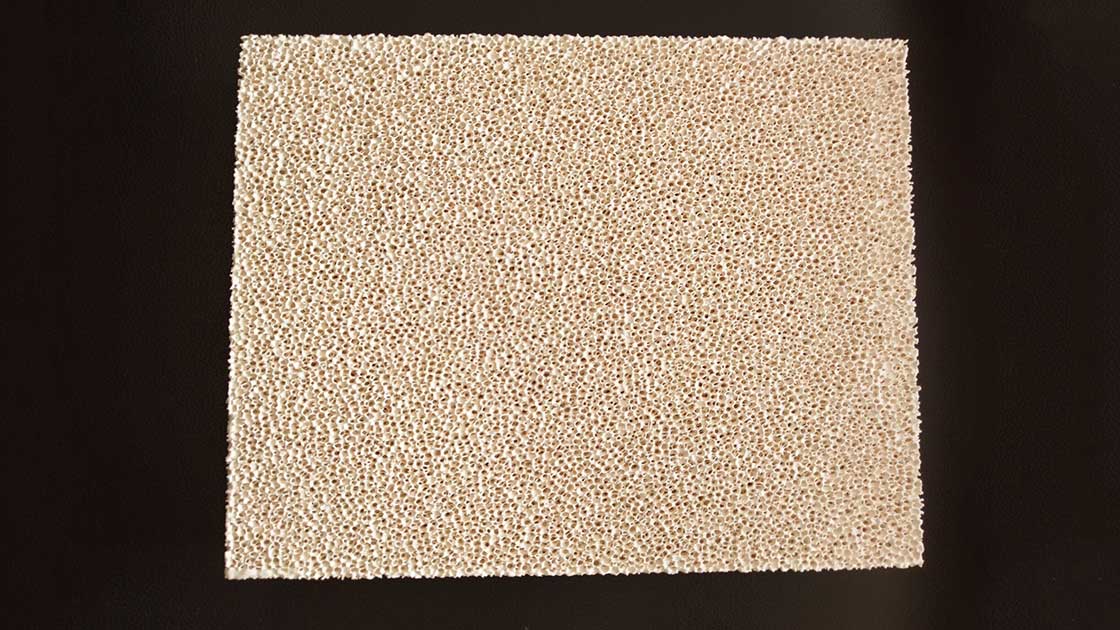

- Regular Sizes and Filtration Capacity

- Technical Parameters

| Size (mm) |

Flow Rate (kg/s) |

Capacity (kg) |

|

| Carbon Steel | Alloyed Steel | ||

| 40×40×20 | 2 | 2.5 | 32 |

| 50×50×22 | 3 | 4 | 50 |

| 55×55×22 | 4 | 5 | 55 |

| 60×60×22 | 3 | 4 | 70 |

| 60×60×25 | 3 | 4 | 70 |

| 75×75×25 | 5 | 6.5 | 105 |

| 100×100×25 | 7 | 10 | 190 |

| 150×150×30 | 17 | 22 | 420 |

| Dia 50×22 | 2 | 3 | 40 |

| Dia 50×25 | 1.5 | 2.5 | 40 |

| Dia 60×25 | 2 | 3.5 | 50 |

| Dia 70×25 | 3 | 4.2 | 70 |

| Dia 75×25 | 4 | 5.5 | 85 |

| Dia 90×25 | 6 | 8 | 115 |

| Dia 100×25 | 7 | 9 | 145 |

| Dia 120×25 | 11 | 14 | 210 |

| Dia 150×30 | 12.5 | 15 | 330 |

| Chemical Composition | ZrO2/SIO2 |

| Porosity (%) | 80~90% |

| Color | Yellow |

| Application Temperature | ≥ 1700°C |

| Compression Strength (Mpa) | ≥1.2 |

| Thermal Shock Resistance | 1100°C—room temperature 6 times |

| Bulk Density | 0.8-0.9g/cm3 |

Functions of Zirconia Ceramic Foam Filters

- Zirconia ceramic foam filters are designed for the molten metal filtration of stainless steel, carbon steel, and large.

- Zirconia filters can filter non-metal slag inclusions and slags as small as micrometers, making the surface of steel casting smoother and reducing machining losses.

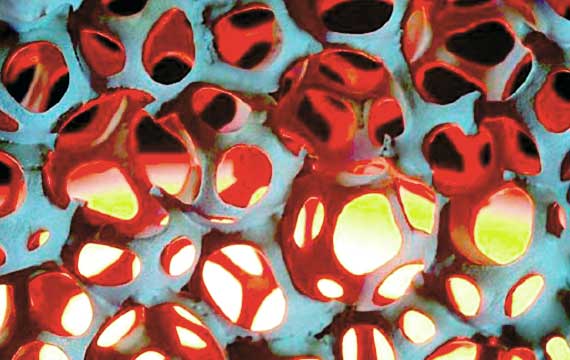

- The pore structure is finally converted into the laminar flow. It fills the cavity better, which may reduce the impact of corrosion of the metal solution on the cavity.

Zirconia Filter Features

The filter body has a typical robust ceramic construction & excellent thermo mechanical properties providing the filter with outstanding stability in operation.

It has good chemical stability & does not react with the alloy liquid, thereby effectively removing the inclusions in the metal liquid & improving the purity of the molten metal.

Application Case of Zirconia Filter in Steel Castings

Take the large-volume piston and cylinder steel castings for large-capacity sluice mechanisms as an example.

Effects of using zirconia filters:

Castings are scrapped during machining before filtration is used.

After using the filter, the casting surface is smooth, the structure is uniform, the strength is improved, and the reject rate is reduced.

FAQs About the Zirconia Filter

As a zirconia filter manufacturer, SEFU has a professional understanding of the use and selection of ceramic foam filters. If you need more information about sic filters, please contact us. Let our professional casting experts customize the foundry solution for you.

Zirconia ceramics are mainly used in piezoelectric ceramic products, daily-use ceramics, refractory materials and zirconium bricks, zirconium tubes, crucibles, etc. for smelting precious metals. It is also used in the production of steel and non-ferrous metals, optical glass and zirconia fibers. It acts as an efficient high-temperature insulation material.

Zirconia filter foam filters help improve the quality of castings and effectively reduce the scrap rate, effectively removing the defects that lead to product quality—slag holes, sand holes, air holes, and other quality problems. It is widely used in iron casting, steel casting, copper casting, aluminum casting, and other casting processes.

The PPI in the filter refers to Pores Per Inch, which is the pore density and pore uniformity of the filter. For example, 10ppi means that the uniformity of pores in any one inch length is 7~13 pores.

Zirconia ceramics are a new type of high-tech ceramics. It has high strength, hardness, high temperature resistance and acid and alkali corrosion resistance. It also has the characteristics of scratch resistance, chemical stability and so on.