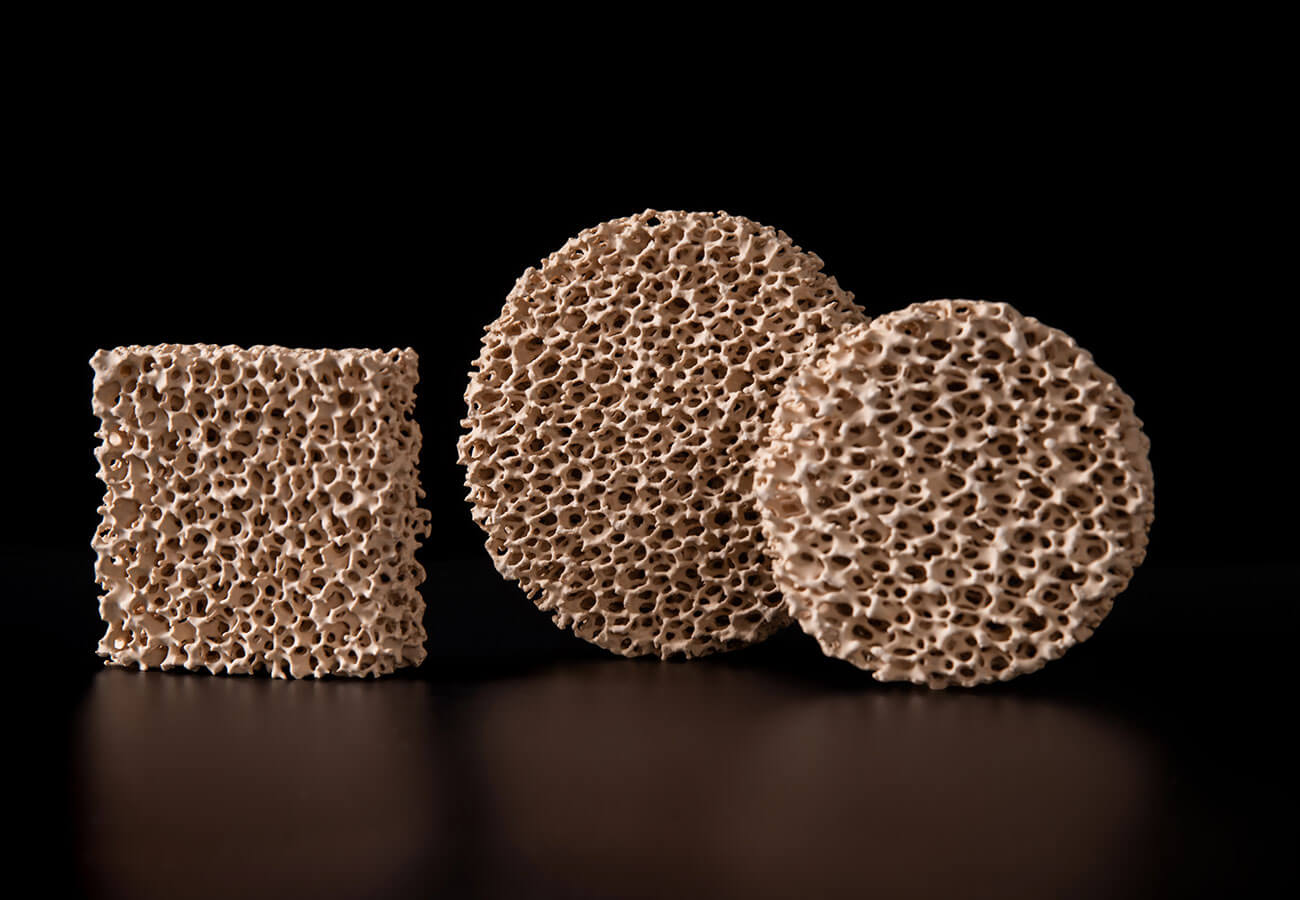

Magnesia Ceramic Foam Filter

Magnesia ceramic foam filter is a good filtration device for magnesium alloy solution. It is a cost-effective and reliable molten metal filtration solution for removing impurities and manufacturing high-quality magnesium castings.

- Improved Casting Quality

- Reduced Machining Costs

- Reduced Scrap and Rework

- Improved Magnesium Alloy Yield

Magnesia ceramic foam filters are designed to remove impurities such as slag, oxides, and other non-metallic particles from the molten magnesium alloy. These particles can cause defects in the casting, which in turn can lead to scrap, rework, and increased production costs.

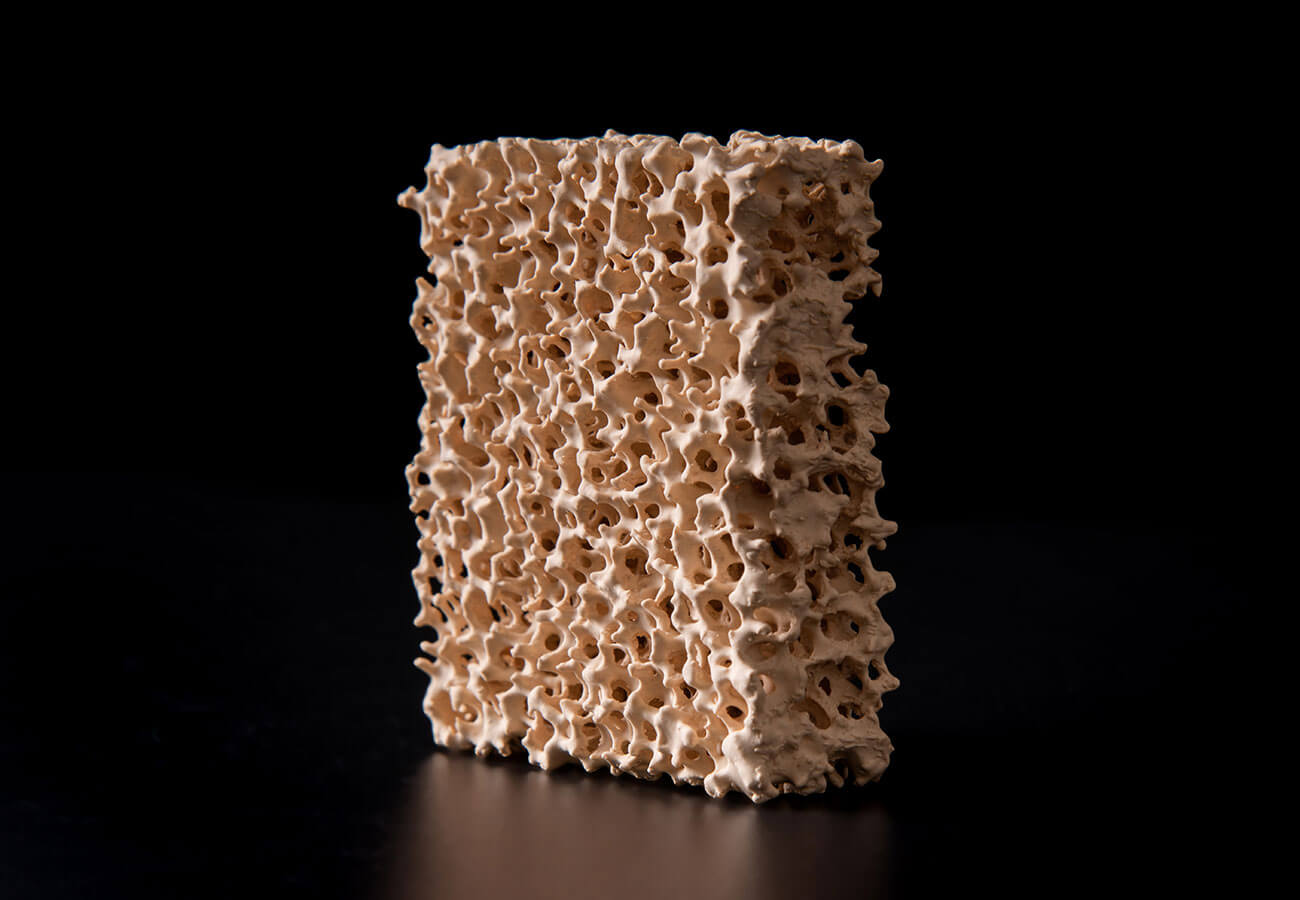

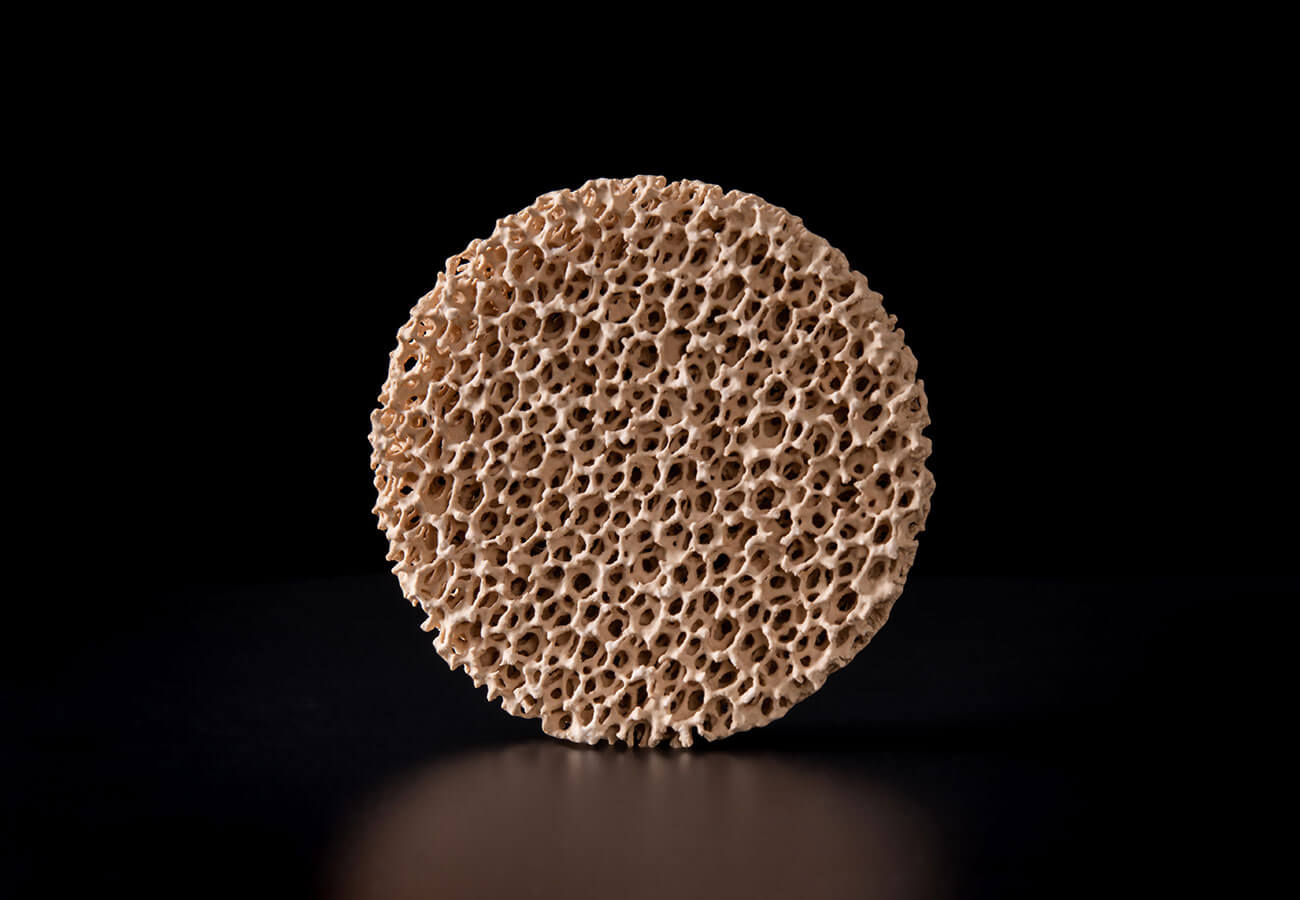

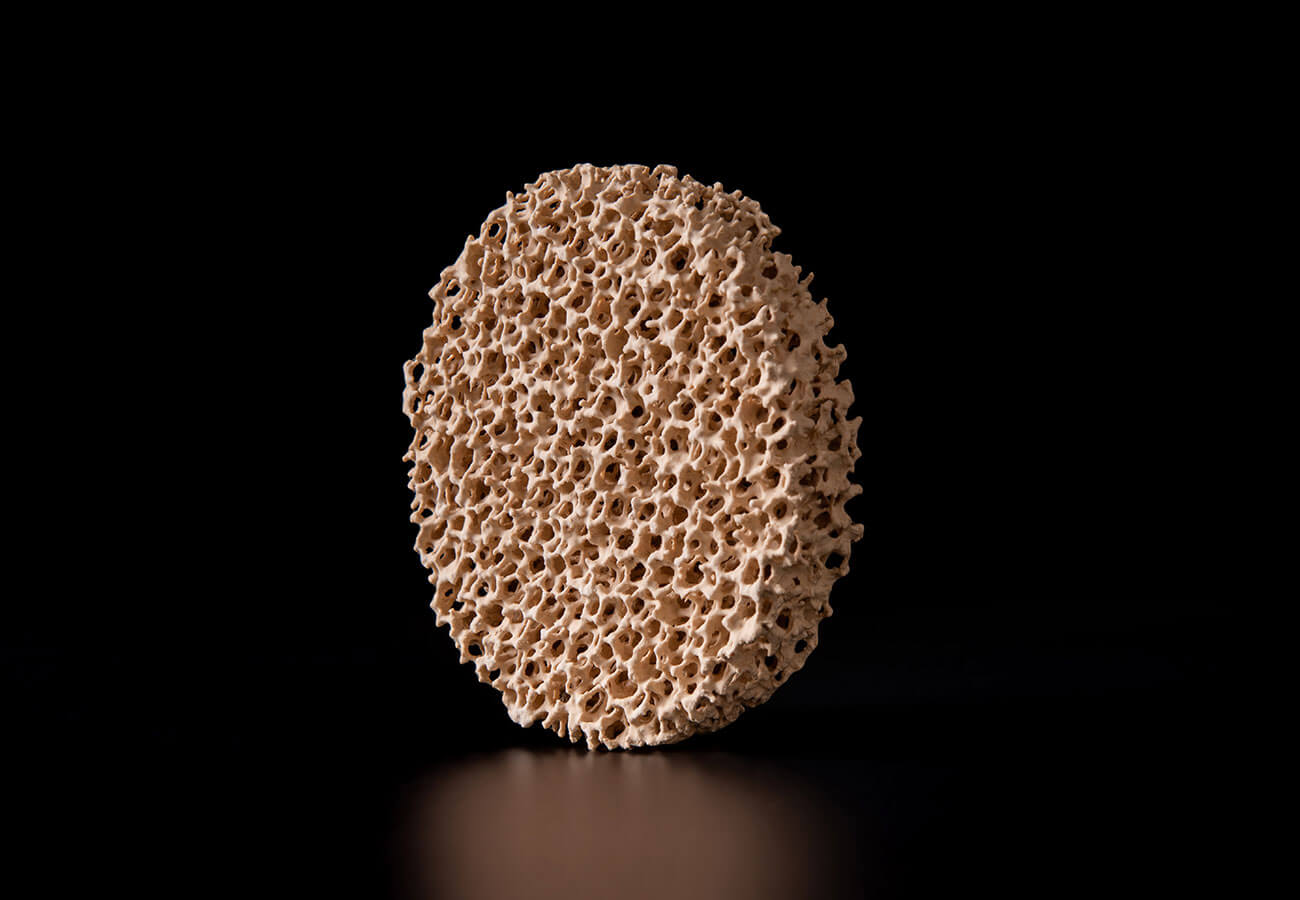

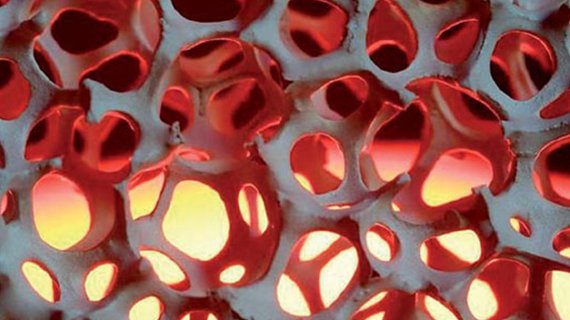

Magnesia ceramic foam filter is a refractory material with high melting points. Its ability to withstand high temperatures makes it ideal for use in the casting process. The ceramic foam filter is characterized by its high porosity, high thermal shock resistance, and high mechanical strength.

- Product Parameters

| Main Composition | Magnesium Oxide |

| Hole Density | 10-60 |

| Porosity | 80-90% |

| Operating Temperature | ≤1200℃ |

| Compressive Strength | 0.6MPa |

How does Magnesia Ceramic Foam Filter work?

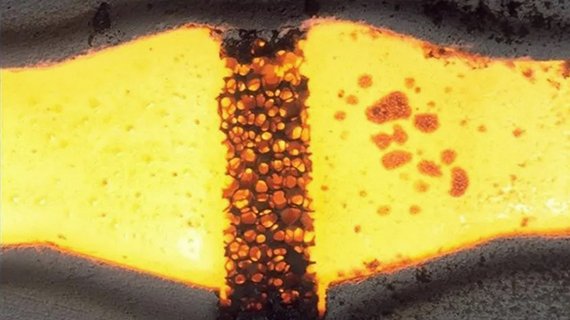

The magnesia ceramic foam filter works by acting as a physical barrier to trap impurities in the molten metal as it passes through. As the molten metal flows through the interconnected pores of the filter, the impurities are retained by the filter, while the clean metal flows out of the filter and into the casting.

Magnesia ceramic foam filter is a very effective molten metal filtration product. Its three-dimensionally connected curved pore network skeleton structure and extremely high porosity make it have a large surface area for slag collection and filtration. It has the advantages of large inner surface area, small flow resistance, and good filtering effect.

Customizable

SEFU magnesia ceramic foam filter has complete specifications, the pore density is from 10 ppi to 60 ppi, and the shapes and sizes can be customized. Send us your detailed drawings to customize the magnesia foam ceramic filter for you.

Related Products

Looking for other molten metal filtration products to improve your casting quality and yield?

Here are our molten metal filtration products of other materials to purify molten aluminum, molten iron, molten steel, molten copper, etc.

FAQ About Magnesia Ceramic Foam Filter

This FAQ part can help you to know more about magnesia ceramic foam filters.

Magnesia Ceramic Foam Filters should be stored in a dry and cool place to prevent any potential damage or contamination. It is also recommended to store them in their original packaging until ready to use.

The longevity of Magnesia Ceramic Foam Filters depends on various factors such as the type of metal or alloy being cast, the casting process conditions, and the size and shape of the filter. However, typically these filters can last anywhere from a few hours to several days.

The benefits of using Magnesia Ceramic Foam Filters include improved casting quality, reduced defects, improved mechanical properties, increased yield, and reduced cost. These filters also improve overall productivity in the casting process.

The Magnesia Ceramic Foam Filter works by allowing the molten metal or alloy to pass through its porous surface, which traps impurities and gases. The filtered metal or alloy then flows out of the filter and into the casting mold.

PPI is the unit pore density, used to represent the average number of pores per inch of length. The larger the PPI value, the smaller the pore, and the smaller the value, the larger the pore. For example, 10 ppi means that there are 10 pores per inch on the magnesia ceramic foam filter.