Fiberglass Mesh Filter Manufacturer

What is Fiberglass Mesh Filter?

Fiberglass mesh filters can effectively remove slags, refractory particles and non-metallic inclusions from molten metals to ensure the production of high-quality castings.

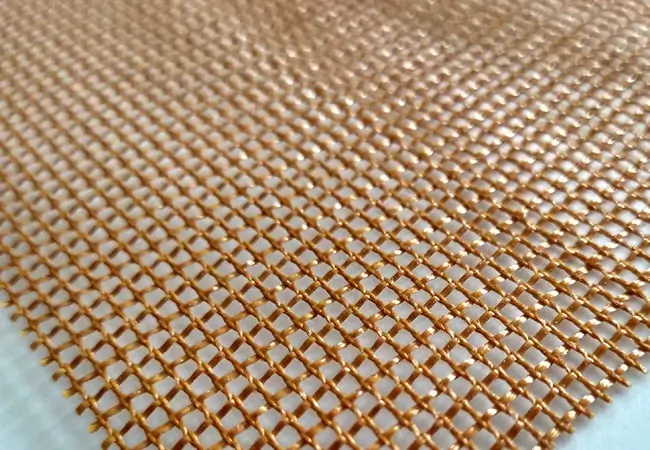

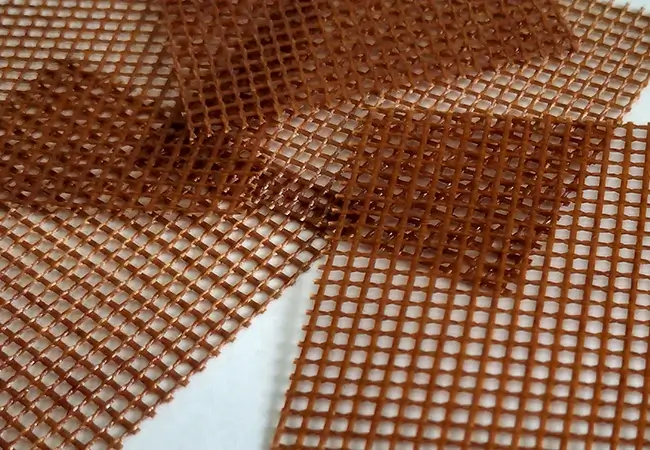

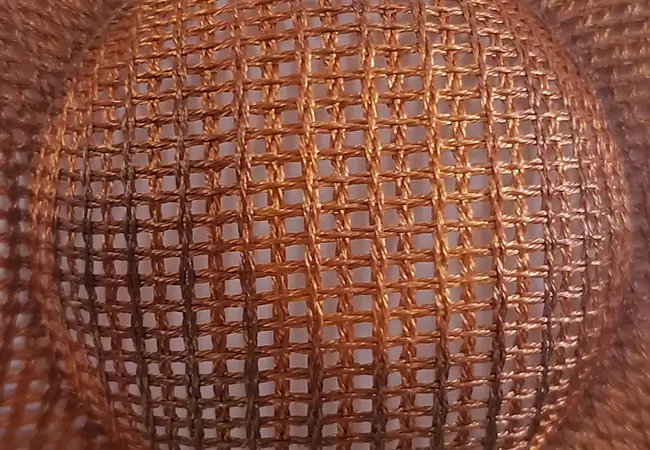

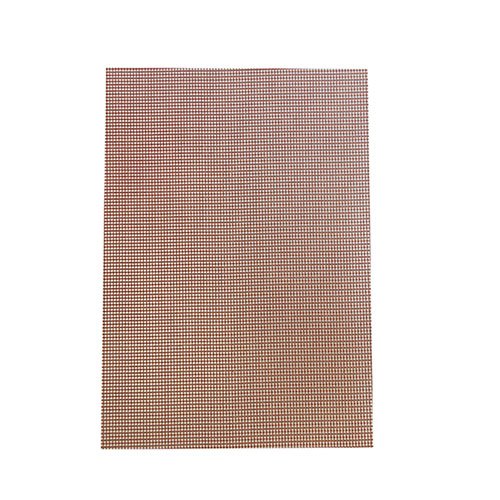

The filters are made of specially treated silica fiberglass yarn and coated with special resin. They are brown with resin coating or black with smokeless carbonized treatment.

The mesh filter acts as a barrier, capturing and trapping unwanted particles, such as slag, sand, or other contaminants, that can compromise the integrity and performance of the final cast products. By effectively filtering the molten metal, the casting filter screen promotes smoother flow, reduces turbulence, and enhances the overall casting quality.

With its durable construction and efficient filtration properties, the casting filter screen is an indispensable tool for achieving consistent and reliable casting results in various industries, including automotive, aerospace, and manufacturing.

SEFU Fiberglass Mesh Filters: Foundry Filter Manufacturers Serving Foundries Worldwide

- Removes micron sized inclusions and impurities.

- Reduce cost, reduce turbulence.

- High-temperature resistance and High filtration efficiency.

- High elastic coefficient and good rigidity.

Types of Molten Metal Filtration

As an integral component, a fiberglass mesh filter is used extensively in foundry casting in the purification of molten iron, steel, and other metals. The foundry filter assists in getting rid of non-metallic impurities, thereby resulting in a cleaner, more high-quality cast.

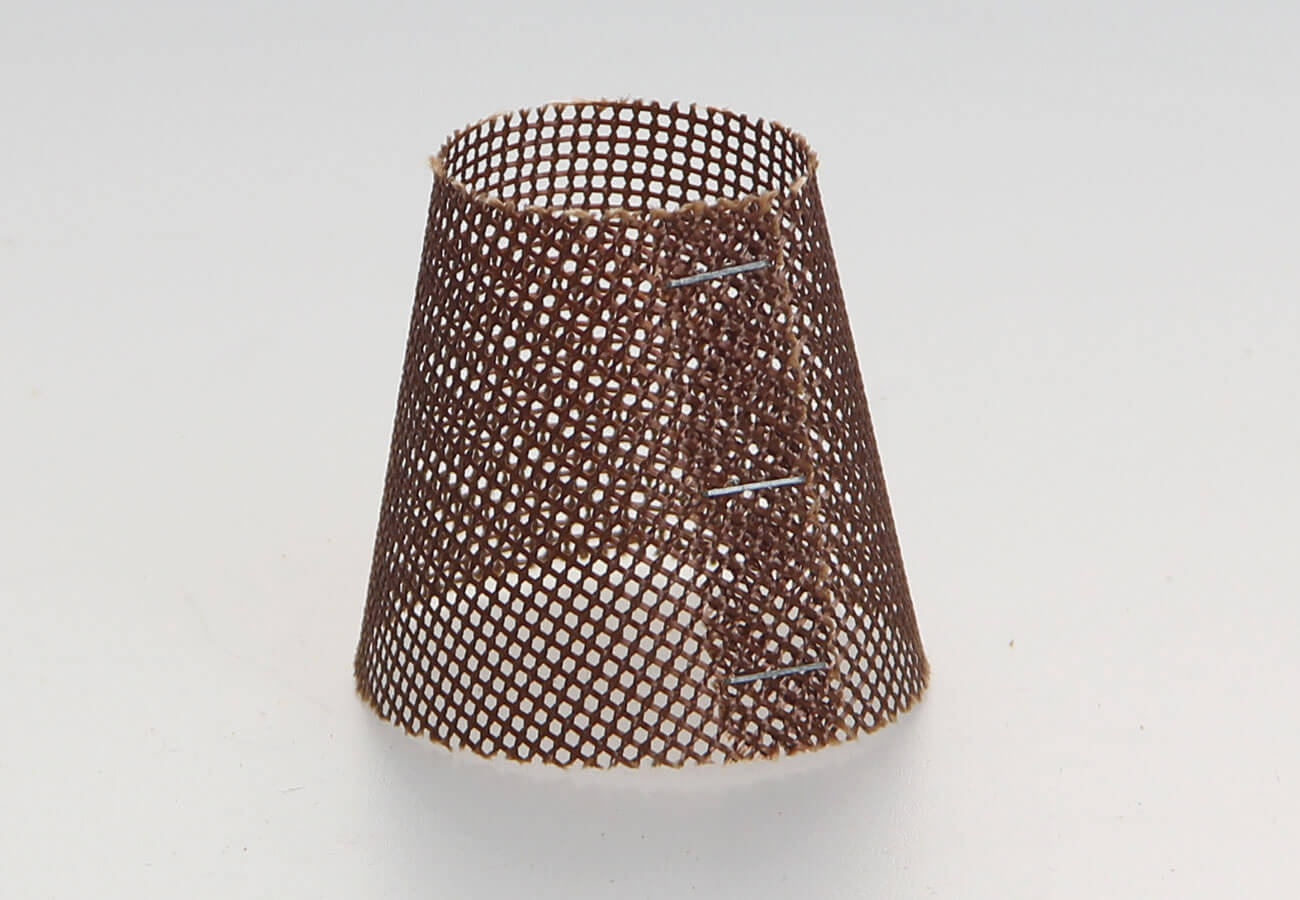

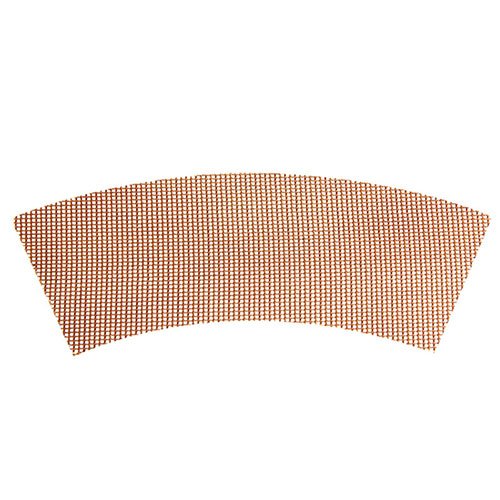

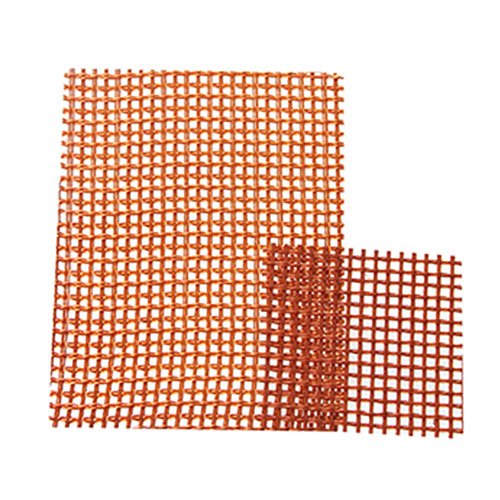

Customizable Sizes & Shapes

A fiberglass mesh filter can be tailor-made according to your specific needs. Whether you need specific hole sizes or shapes, these filters (including silica mesh) can be customized to suit your application requirements.

SEFU filters can be customized according to your request

SEFU filters are suitable for iron, copper, aluminum, and steel alloys, etc.

Casting filters are available for 1700°C.

We supply you ceramic filter samples

Why Choose SEFU Fiberglass Mesh Filter?

SEFE aims to provide quality casting materials to the world and build a high-quality brand of casting filters.

Relying on our technology center, we establish a product network information system, from raw material inspection, weighing control, size control, formula management, process monitoring, and monitoring of the entire product manufacturing network to avoid human errors.

Our service team can provide you with the best quality service efficiently and quickly.

High Silica Fiberglass Mesh Filter

SEFU high silica fiberglass mesh filter is made of high-grade high-temperature resistant fiber through a special process. High silica fiber is a high temperature resistant inorganic fiber with excellent ablation resistance, heat insulation, and thermal insulation properties.

Fiberglass Mesh Filter Video

Molten Metal Filter Applications

Fiberglass filters can be used in aluminum alloy castings to remove inclusions from molten aluminum.

Fiberglass mesh filters can be used to remove impurities in molten iron from gray castings, ductile iron, and other iron castings.

Fiberglass mesh filters are also suitable for steel castings. It can remove inclusions in small and medium-sized steel castings and improve casting quality.

Choose Your Ceramic Foam Filter

- More Applications

- Data Sheet

| Product Name | Working temperature | Melting point | Sustaining working time | Tensile strength | Application |

| Steel fiberglass mesh filter | 1600-1620 | 1700 | 5 minutes | 16 | Carbon steel, stainless steel casting filtering |

| Iron fiberglass mesh filter | 1400-1450 | 1700 | 10 minutes | 8 | Grey iron, nodular iron and small size steel casting filtering |

| Copper fiberglass mesh filter | 1200 | 1700 | 10 minutes | 6 | Copper alloy casting filtering |

| Alumina fiberglass mesh filter | 700-800 | 900 | 10 minutes | 6 | Aluminum alloy casting filtering |

| Cap-style mesh filter | – | – | – | – | Various casting filtering |

Related Product

FAQ About Fiberglass Mesh Filters

Are you still more confused about fiberglass mesh filters?

This section is more about fiberglass mesh filters. Let’s explore more mysteries about this molten metal filter together.

Fiberglass mesh filter is a high temperature resistant inorganic fiber material. It removes impurities from the molten metal. Choosing a high-silica glass fiber filter can fully meet your needs for small castings.

High silica fiberglass mesh filter is an excellent inorganic material with high temperature resistance, heat insulation, and heat preservation. It can work continuously at a temperature of 900°C, and can withstand a short-term temperature of 1700°C.

The fiberglass mesh filter is woven from glass fibers. The surface of the high-silica fiberglass mesh filter is coated with a high temperature resistant coating. Finally, a filter screen with a certain rigidity is produced.

Fiberglass mesh filters can be used to filter and purify impurities in metal smelting and casting. It is suitable for the filtration of small and medium-sized steel castings, gray castings, ductile iron and small steel castings, copper alloy castings, aluminum alloy castings, etc.