Blind Riser

SEFU manufacturer of blind risers and organized a new blind riser system that was able to improve casting yield. It reduces labour, energy costs for large carbon and low alloy steel castings.

- Blind riser may not increase with the height of the flask.

- Heat dissipation of the blind riser is slower than the open riser.

- It increases casting output.

- It can reduce labour.

- No debris will enter the cavity after the process of the blind riser is closed.

- B Type Straight Tube Blind Exothermic Riser Sleeve

- Our Certification

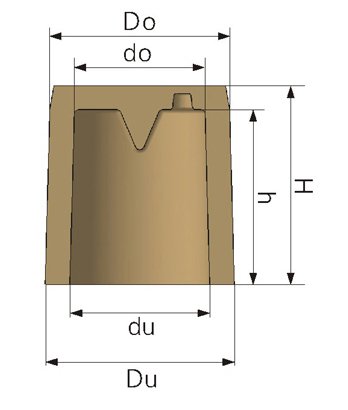

| Specification/Model (du*H) |

Effective modulus (cm) |

Size (mm) | Volume (CC) | |||||

| du | Du | do | Do | h | H | |||

| B4/7 | 1.20 | 41.5 | 62.5 | 35.5 | 59 | 63 | 71.5 | 70 |

| B5/8 | 1.50 | 52 | 73.5 | 48 | 70 | 70 | 80 | 130 |

| B6/9 | 1.70 | 57.5 | 80 | 52.5 | 76 | 78.5 | 91 | 180 |

| B7/10 | 2.00 | 69.5 | 94 | 65 | 89 | 87 | 99 | 300 |

| B8/11 | 2.25 | 79 | 102 | 71.5 | 99 | 96.5 | 108 | 420 |

| B9/12 | 2.50 | 89 | 119 | 81 | 110 | 104.5 | 120 | 580 |

| B9/18 | 2.68 | 89 | 119 | 81 | 110 | 164.5 | 180 | 890 |

| B10/13 | 2.80 | 97 | 127.5 | 91 | 119.5 | 118 | 133 | 800 |

| B11/14 | 2.91 | 108 | 138 | 101 | 130 | 123 | 140 | 1000 |

| B12/15 | 3.20 | 118 | 154.5 | 112 | 148 | 130 | 150 | 1350 |

| B14/17 | 3.73 | 140 | 182 | 131 | 173 | 149 | 170 | 2140 |

What are Blind Risers?

The blind riser is a type of riser sleeve. The feeder is based on the variation of casting structure and some castings are used as the best way. It improves the process yield of castings. A blind riser for use in the casting of metals. It normally has a round or oval cross-section and has a domed or flat cover on the inner surface of the cover to improve and stabilize the riser effect.

How to use the blind riser?

Blind risers are high metal fronts that are not exposed to the atmosphere. Blind risers are situated in the beneath section of castings, or just concealed at a level below the upper most risers as well as the open risers. They portray as reservoirs that supply liquid metal into casting as it deals with solidifying.

Basic Performance of Enhancing Blind Risers

Distributing blind risers with tolerable passage to the meteorological air and heating with the top metal front will increase the casting yield. It can be reducing the cost of energy. Blind risers, or closed risers, are used to feed various casting sections. Although they can be indispensable when feeding certain complex configurations, presented with escalating raw material and energy costs, ferrous metal caster Blind risers, or closed risers, are mainly used for sustaining the various casting divisions.

FAQs About the BLIND RISERS

Read this section to understand why we need Blind Risers. If you need to know other information about riser sleeves, please leave your questions and let our experienced service team serve you.

It is used to feed different castings to increase production. Even if they can be indispensable when engorgement is certain sophisticated configurations, they are less efficient than open blind risers and must have free passage to the outside atmosphere. The heat dissipation of the blind riser is slower than that of the open riser, and the feeding efficiency is higher, which can save the riser molten metal.

The blind riser in casting can be used in the production of large, medium, and small cast steel, ductile iron, gray iron, and non-ferrous alloys.

- It improves the yield of casting.

- It does not enhance to the outer surface of a mold.

- It curtails labour efficiency.

- It has increased the casting output.

- It does not increase with the height of the flask.