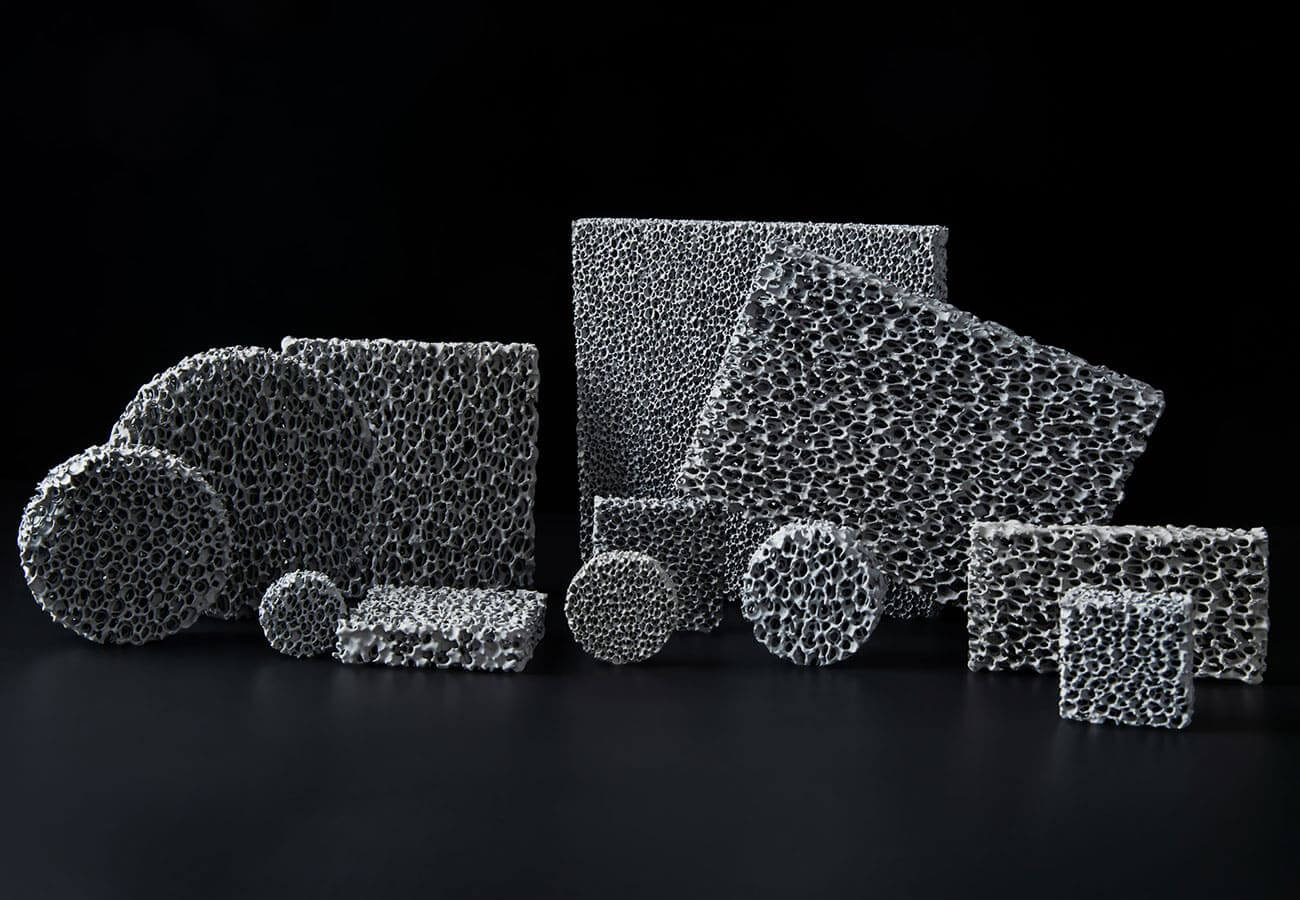

SF-Foundry Ceramic Foam Filters

SF-Foundry is a leading company focusing on the research, development, production and sales of high-performance ceramic foam filters. We are committed to providing high-quality filtration solutions to the global foundry industry, helping customers improve casting quality, reduce production costs and improve production efficiency. With advanced production technology, strict quality control system and professional technical support, SF-Foundry has become a reliable partner for many foundry companies.

Ceramic foam filters, the casting filters, are used to filter solid particulates and slag from molten metal before it is poured into the mold. This helps reduce trapped gases, provides a smoother laminar flow, and results in cleaner metal, ensuring an even surface on the casting and a scrap-free yield.

Our foam filters are suitable for ferrous metals, molten aluminum, and copper-based alloy filtration, with a maximum temperature tolerance of 1700°C. They offer high thermal stability, with a 0% likelihood of cracking or failure. These 3-dimensional open-pore filters excel at producing molds free of oxides and inclusions.

Yield superior casting purity with a reduced scrap rate using SF-Foundry’s ceramic foam filters. Our foam filters are custom-built in all sizes and thicknesses to suit all types of applications.

Can be customized according to your request

Suitable for iron, copper, aluminum, and steel alloys, etc.

Available for temperatures ranging from 900°C to 1700°C.

We supply you ceramic filter samples

SF-Foundry Ceramic Foam Filter Features

- SF-Foundry ceramic foam filter uses high-quality polyurethane sponge as a raw material to ensure that the premium quality of the filter can meet your production needs.

- The open-cell, 3D lattice structure increases the surface area, allowing for more effective trapping of non-metallic inclusions and slag particles.

- The filters can withstand temperatures of up to 1700°C without degrading or melting during the filtration process.

- Optimum porosity ensures that molten metal flows through the porous ceramic filter smoothly, without causing blockages or turbulence.

- The filtration process is consistent across all types, ensuring stability for mass production.

- Thanks to their mechanical strength, the filters can handle high-pressure operations without breaking down or shedding debris.

Advantages of Ceramic Foam Filters

- It can be easily integrated into existing pour basins or gating systems.

- Good porosity and allows the metal to flow through the pores without clogging or forming barriers.

- Adaptable to both horizontal and vertical placements.

- Chemical resistance to molten aluminum and other corrosive alloys.

- Offers superior thermal shock resistance and durability against erosion from the molten metal’s high velocity and abrasiveness.

Application

Ceramic foam filters can be used in casting processes including but not limited to:

- Non-ferrous casting

- Grey and ductile iron casting

- Sand casting

- Permanent mould casting

- Investment casting

Why choose SF-Foundry?

As a professional manufacturer of ceramic foam filters, SF-Foundry not only provides high-performance ceramic filters for casting, but also provides customers with comprehensive technical support and customized solutions. Our team has rich industry experience, can quickly respond to customer needs, and provide full technical guidance from selection to use.

Whether it is a small or medium-sized foundry or a large high-end manufacturing company, SF-Foundry can provide you with reliable and efficient filtration solutions. Choosing SF-Foundry means choosing a trustworthy partner for you!

- Professional technical support: provide full technical support from selection to use.

- Fast delivery: efficient production and logistics system to ensure timely delivery.

- Customized solutions: provide personalized products and services according to customer needs.

Application Examples

More Details About Ceramic Foam Filters

- Customized Cases: Specialized Filter

- Our Packaging

- Data Sheet

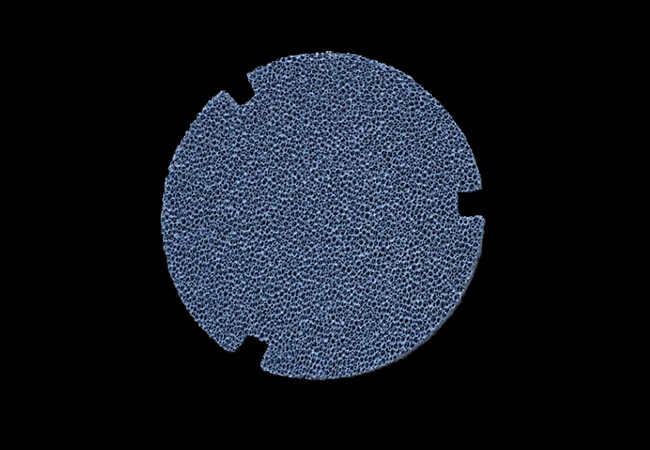

As a ceramic foam filter manufacturer, SF-Foundry produces ceramic foam filters in unconventional shapes and sizes according to your needs.

Customized ceramic filters for casting in different shapes according to your requirements.

| Item | SiC Ceramic Foam Filter | Alumina Ceramic Foam Filter | Zirconia Ceramic Foam Filter |

| Color | Grey/Black | White | Yellow |

| Pore Density | 10-40 PPI | 10-40 PPI | 10-40 PPI |

| Porosity | 80%-90% | 80%-90% | 80%-90% |

| Operating Temperature | ≤1500 ℃ | ≤1100 ℃ | ≤1700 ℃ |

| Bending Strength | ≥0.8 MPa | ≥0.6 MPa | ≥1.0 MPa |

| Thermal Shock Resistance | 6 Times/1100℃ | 6 Times/1100℃ | 6 Times/1100℃ |

| Application | Ductile Iron, Gray Iron, Other Cast Iron, and Non-ferrous Alloy | Aluminum, Aluminum Alloys, and Other Non-ferrous Alloys | Stainless Steel, Carbon Steel, and Large Cast Iron |

Related Product

FAQ About Ceramic Foam Filters

Would you like to learn more about ceramic filters?

Do you have any questions about ceramic foam filters?

Let us know! Let the ceramic foam filter manufacturer answer your questions.

Define your application. Filter through SF-Foundry’s official site based on the materials being poured, temperature resistance, filter size & shape, and pore size. If you need further assistance, feel free to contact our team, and we’ll be happy to help.

We provide a range of foam filters, with properties that change from one material to another, and so does their temperature tolerance. Filters can operate at a maximum temperature of 1700°C.

Our filters are used to remove non-metallic inclusions, such as oxides, slag, and other contaminants from molten metals.

The filters remove impurities from the molten metal, resulting in a cleaner flow. This helps initiate a laminar flow through the mold, reducing turbulence. It significantly minimizes the need for fettling work on the final products, leading to substantial cost savings.

A brand defines its value by the reputation it builds over the years. At SF-Foundry, we’ve established our reputation in ceramic foam filter manufacturing by delivering ISO-certified products for over a decade.