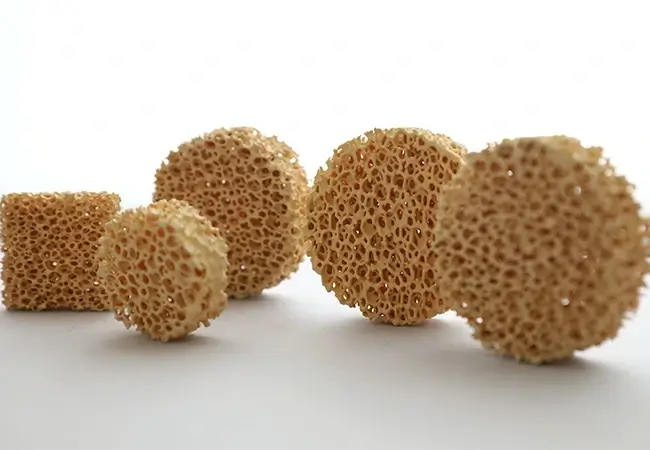

Zirconia Foam Filters for Metal Purification in Precision Casting

Zirconia Foam Filters are advanced ceramic filters designed to remove impurities from molten metals during the production process. With their exceptional performance and versatility, these filters are widely used in precision casting applications, including the aerospace industry. Experience the benefits of SEFU Zirconia Foam Filters for superior metal purification and enhanced casting quality.

Applications of Zirconia Foam Filters

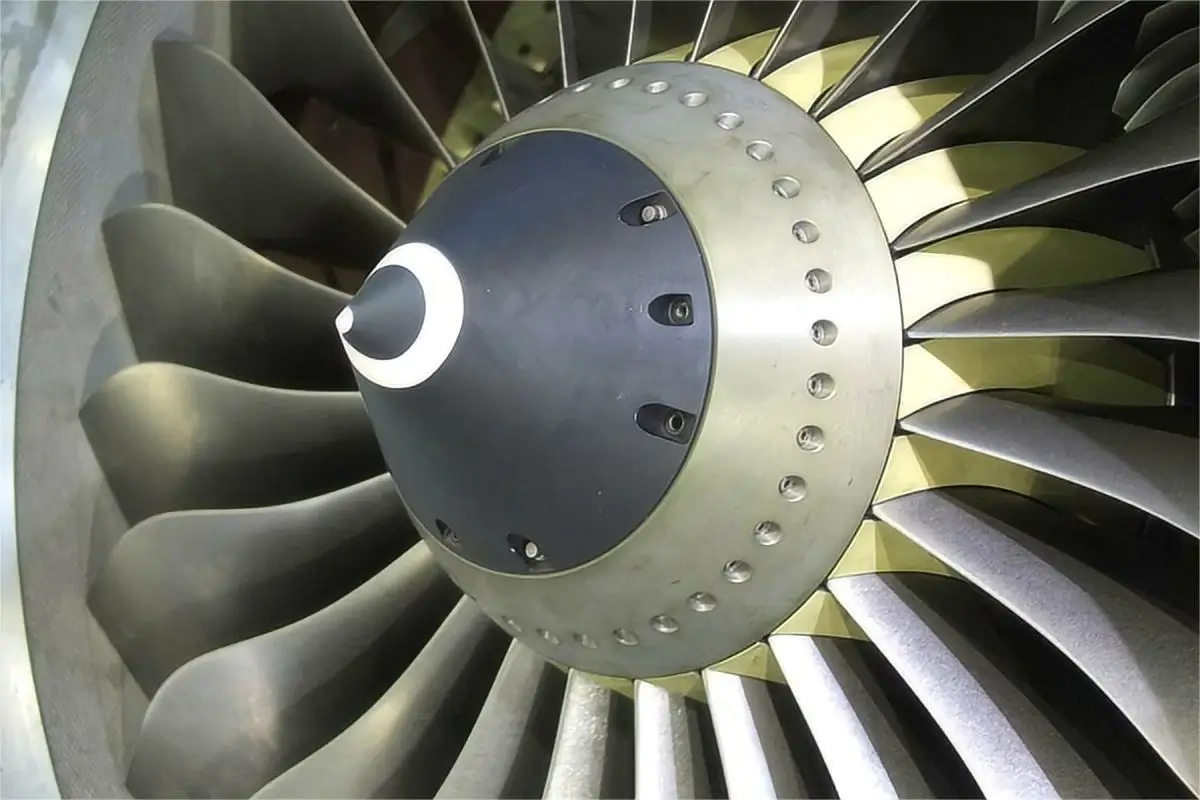

SEFU Zirconia Foam Filters find extensive usage in precision casting applications, particularly in the aerospace industry. They effectively remove impurities from molten metals, ensuring the production of high-quality and defect-free castings for critical components and precision parts.

- Product Parameters

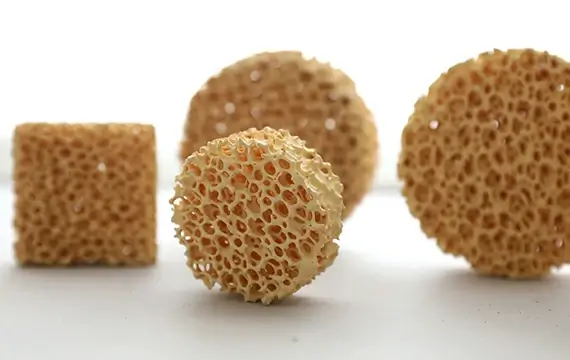

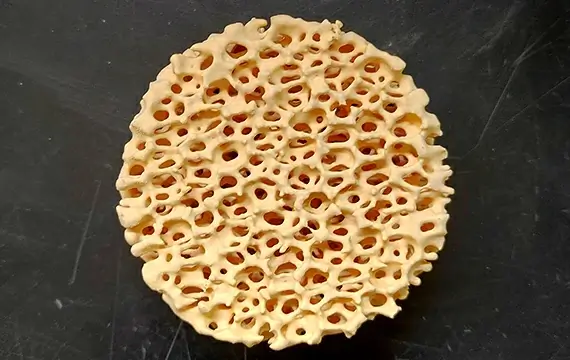

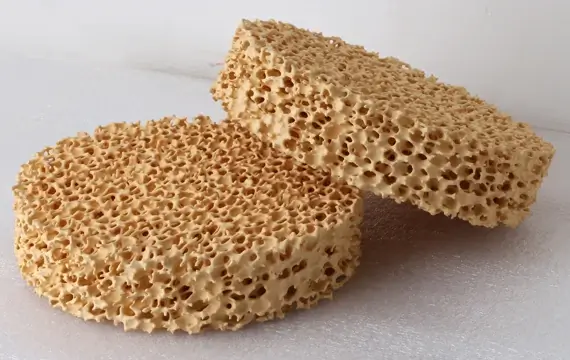

| Pore Density (PPI) | 10–40 |

| Porosity (%) | 80-90 |

| Max Working Temperature (ºC) | 1700 |

| Bending Strength (Mpa) | 0.8-1.0 |

| Compressive Strength (Mpa) | 1.0-1.2 |

| Thermal Shock Resistance (times/1100-0ºC) | 6 |

Key Features of Zirconia Foam Filters

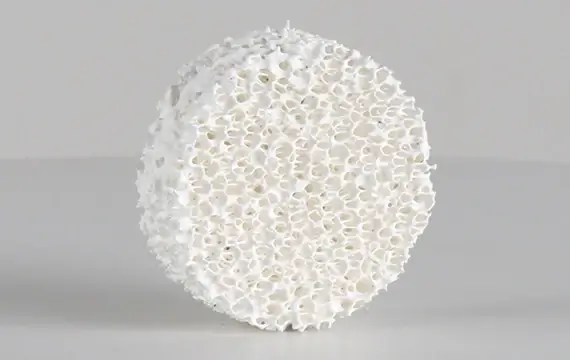

High-Purity Zirconia Material: Our filters are made from high-quality zirconia, ensuring optimal filtration efficiency and excellent thermal stability.

Effective Impurity Removal: Zirconia Foam Filters effectively remove impurities from molten metals, enhancing the overall quality and properties of the castings.

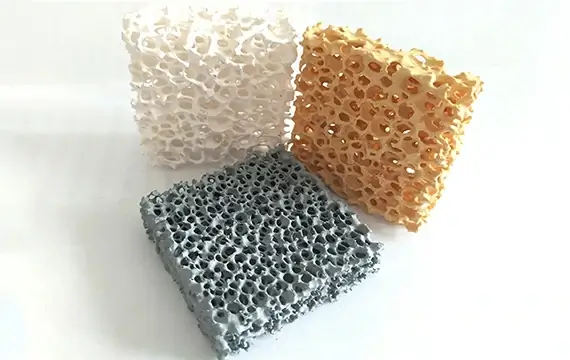

Wide Compatibility: Suitable for casting steel, copper, and iron alloys, these filters are highly versatile and can be applied in various production processes.

Precision Casting Applications: Ideal for precision casting in industries like aerospace, where high-quality and defect-free castings are crucial for performance and safety.

Advantages of SEFU Zirconia Foam Filters

Enhanced Casting Quality: The efficient impurity removal capability of our filters results in superior casting quality, reducing defects and improving mechanical properties.

Exceptional Thermal Stability: With a high-temperature resistance up to 1700°C , our filters maintain their structural integrity even in demanding casting conditions.

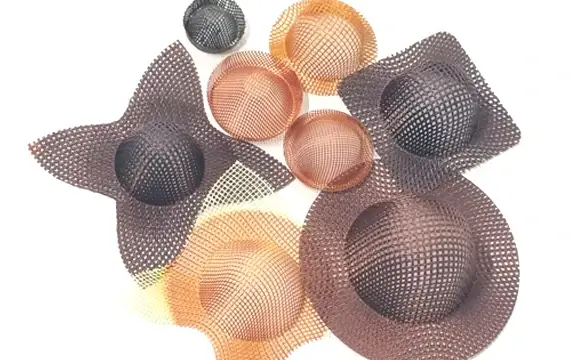

Tailored Solutions: We offer a range of customizable options, including different pore sizes and shapes, allowing you to select the optimal filter design for your specific casting requirements.

Reliable and Trusted: SEFU is a renowned manufacturer of advanced ceramic filters, trusted by industries worldwide for delivering high-performance products and exceptional customer service.

Why Choose SEFU?

Industry Expertise: With years of experience in the field, SEFU specializes in manufacturing advanced ceramic filters tailored to the needs of precision casting applications.

Premium Quality: Our Zirconia Foam Filters undergo rigorous quality control measures, ensuring consistent performance and reliability.

Technical Support: Our knowledgeable team of experts provides technical assistance and guidance to help you select the most suitable filter design for your specific casting requirements.

Customer Satisfaction: We prioritize customer satisfaction and are committed to delivering products that meet and exceed your expectations.

Related Products

Available in a wide range of refractory ceramic casting materials for your casting production.

Unlock the Potential of Zirconia Foam Filters:

SEFU Zirconia Foam Filters offer exceptional metal purification capabilities, enabling the production of high-quality and defect-free castings in precision casting applications. Experience the superior performance and reliability of our filters today to achieve optimal casting results in your manufacturing processes.