Zirconia Filter For Foundry: Enhance Your Metal Casting Process

Welcome to our comprehensive guide on Zirconia Filters for Foundries. If you’re looking to optimize your metal casting process, improve metal quality, and minimize defects, you’re in the right place. Our Zirconia Filters are engineered to deliver exceptional performance, ensuring smooth operations and superior results.

Applications

Our Zirconia filters find widespread applications across various metal casting processes, including:

- Steel Casting

- Aluminum Casting

- Iron Casting

- Copper Alloy Casting

- And more…

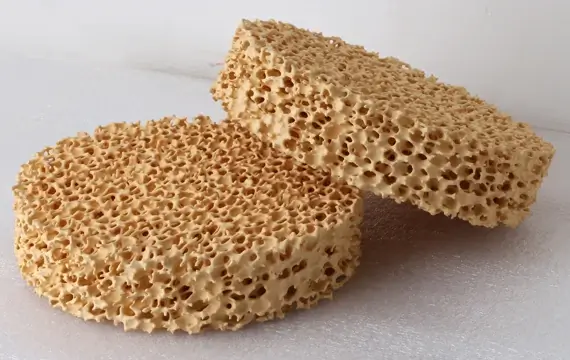

- Product Parameters

| Pore Density (PPI) | 10–40 |

| Porosity (%) | 80-90 |

| Max Working Temperature (ºC) | 1700 |

| Bending Strength (Mpa) | 0.8-1.0 |

| Compressive Strength (Mpa) | 1.0-1.2 |

| Thermal Shock Resistance (times/1100-0ºC) | 6 |

Key Features of Our Zirconia Filters

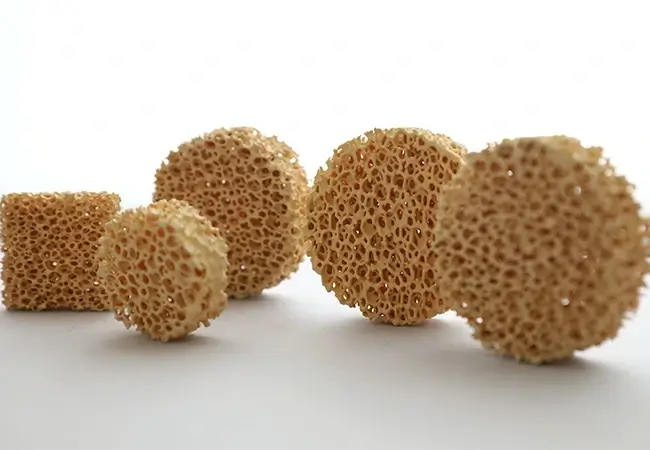

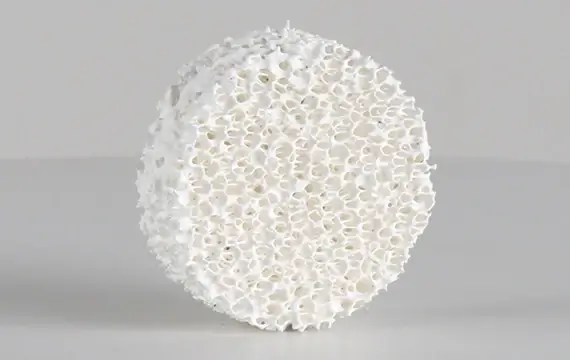

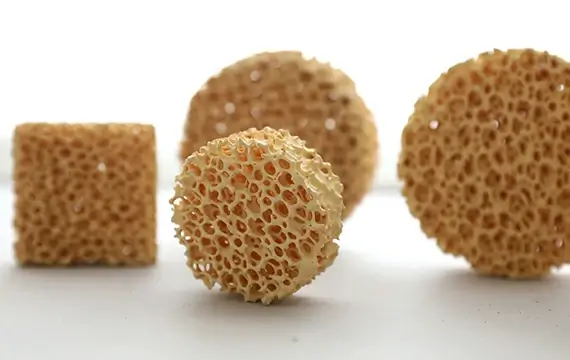

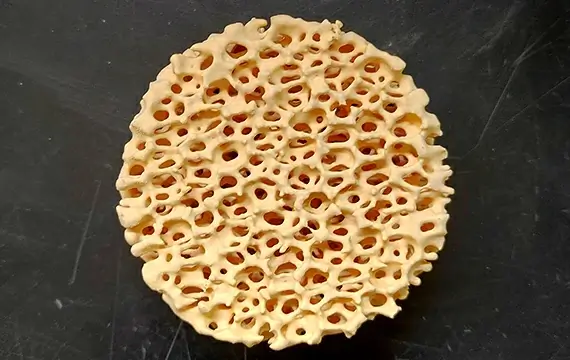

- Uniform Pore Structure: Each filter is meticulously manufactured to achieve a consistent and uniform pore structure, ensuring reliable filtration and consistent casting quality.

- High Strength: Zirconia filters are renowned for their exceptional mechanical strength, minimizing the risk of breakage or deformation during handling and casting operations.

- Easy Installation: Designed for convenience, our Zirconia filters are easy to install, saving time and effort in the foundry setup process.

- Cost-Effective: Despite their premium quality and performance, our Zirconia filters are competitively priced, offering exceptional value for money.

Why Choose Zirconia Filters?

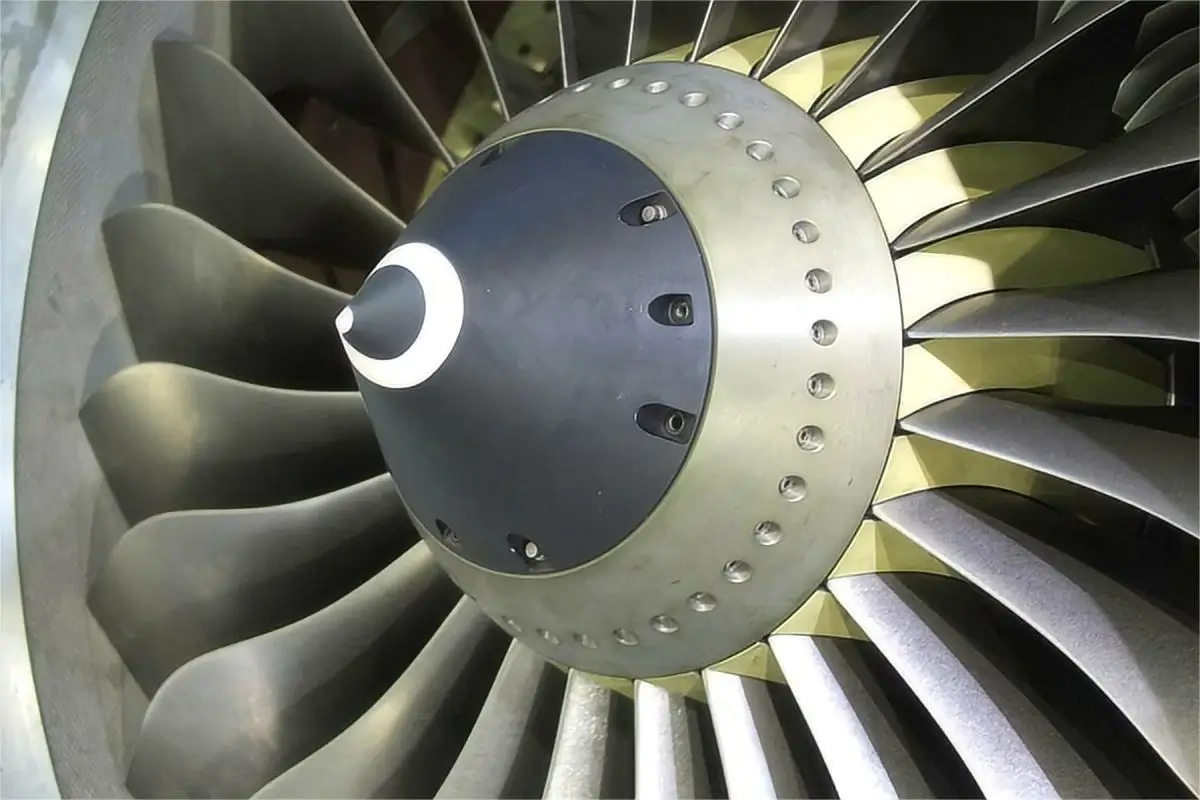

Zirconia filters play a crucial role in the foundry industry by effectively removing impurities and inclusions from molten metal. Here’s why they are preferred:

- High Thermal Stability: Zirconia filters can withstand extreme temperatures encountered during the metal casting process, ensuring consistent performance without compromising structural integrity.

- Excellent Filtration Efficiency: With a precisely engineered porous structure, our Zirconia filters efficiently trap impurities and inclusions, leading to cleaner molten metal and improved casting quality.

- Chemical Inertness: Zirconia is highly resistant to chemical reactions, preventing any unwanted interactions between the filter and the molten metal, thus maintaining the purity of the casting.

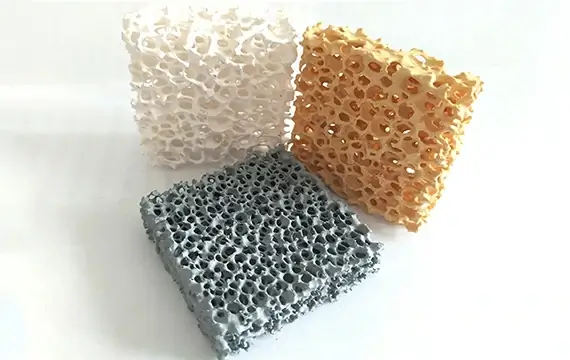

- Customizable Options: Our Zirconia filters are available in various shapes, sizes, and configurations to suit different foundry applications, ensuring compatibility and optimal performance.

Quality Assurance

We understand the critical importance of quality in metal casting operations. That’s why our Zirconia filters undergo rigorous quality control measures to ensure they meet the highest industry standards. From material selection to final inspection, every step is meticulously executed to deliver products that exceed customer expectations.

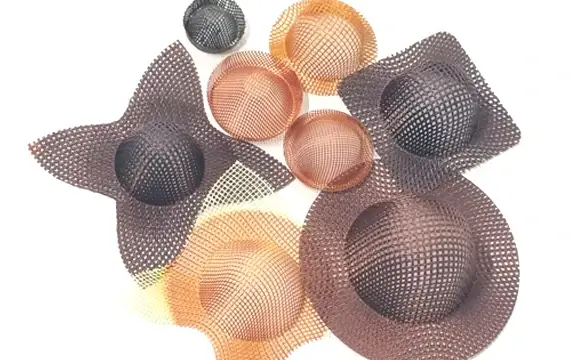

Related Products

Available in a wide range of refractory ceramic casting materials for your casting production.

Contact Us:

Ready to optimize your metal casting process with our premium Zirconia filters? Get in touch with our knowledgeable team today to discuss your specific requirements, and let us help you achieve superior casting quality and efficiency.