Zirconia Ceramic Filter: Revolutionize Your Metal Casting Process

Welcome to the forefront of metal casting innovation with Zirconia Ceramic Filters. Engineered to perfection, our filters are the epitome of excellence in the foundry industry, designed to elevate your metal casting operations to unprecedented levels of quality and efficiency.

Applications

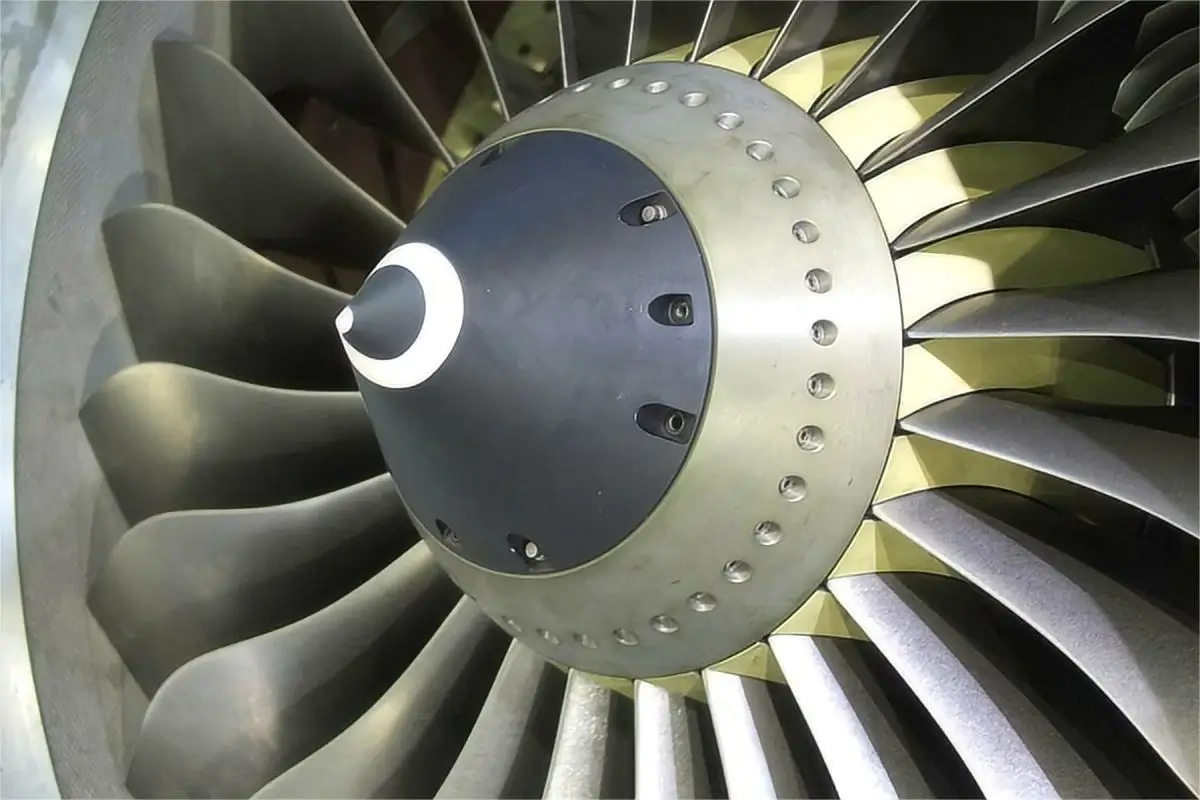

Our Zirconia Ceramic Filters find wide-ranging applications across various metal casting processes, including:

- Steel Casting

- Iron Casting

- Aluminum Casting

- Copper Alloy Casting

- And more…

- Product Parameters

| Pore Density (PPI) | 10–40 |

| Porosity (%) | 80-90 |

| Max Working Temperature (ºC) | 1700 |

| Bending Strength (Mpa) | 0.8-1.0 |

| Compressive Strength (Mpa) | 1.0-1.2 |

| Thermal Shock Resistance (times/1100-0ºC) | 6 |

Unleash the Power of Zirconia Ceramic Filters

Zirconia Ceramic Filters stand as a testament to technological advancement in the realm of metal casting. Here’s why they’re the preferred choice for discerning foundries:

- Unmatched Thermal Resistance: With a staggering tolerance of up to 1700 degrees Celsius, our Zirconia Ceramic Filters effortlessly withstand the extreme temperatures encountered during metal casting processes, ensuring uninterrupted performance and longevity.

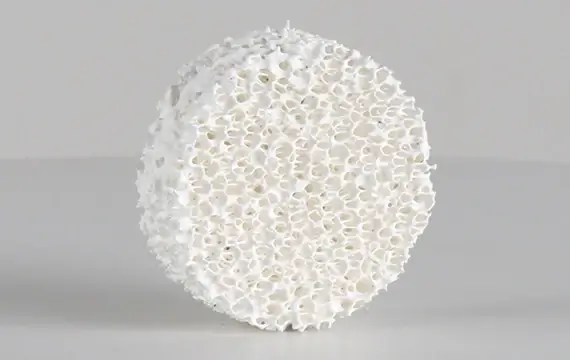

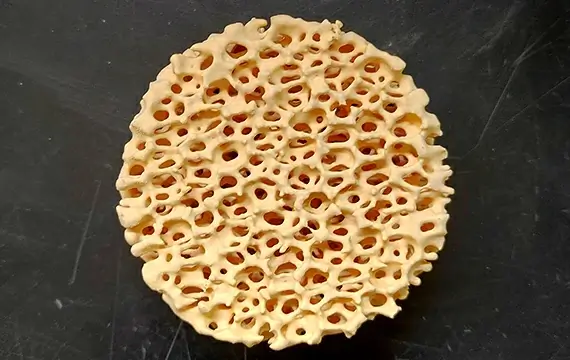

- Precise Porosity Control: Featuring pore sizes ranging from 10 to 40 PPI (pores per inch), our filters offer unparalleled filtration efficiency, effectively capturing impurities and ensuring the production of high-quality, defect-free castings.

- Enhanced Metal Quality: By effectively removing impurities such as oxides, slag, and non-metallic inclusions, our Zirconia Ceramic Filters contribute to the production of cleaner, more refined metals, resulting in superior casting quality and mechanical properties.

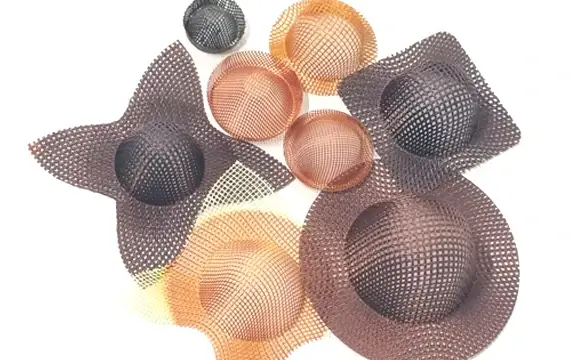

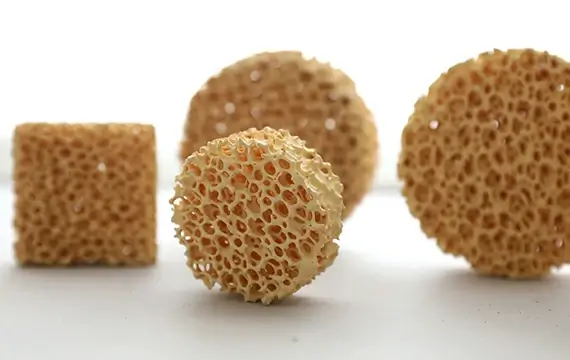

- Customized Solutions: Tailored to meet the diverse needs of foundries, our Zirconia Ceramic Filters are available in a range of shapes, sizes, and configurations, allowing for seamless integration into various casting processes.

Key Features of Our Zirconia Ceramic Filters

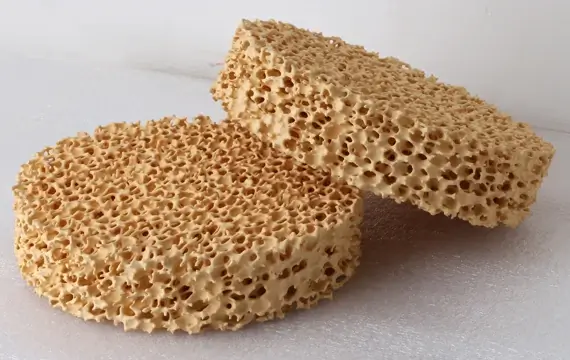

- Robust Construction: Crafted from premium zirconia ceramic materials, our filters boast exceptional mechanical strength and durability, ensuring reliable performance in demanding foundry environments.

- Consistent Porosity: Each filter is meticulously engineered to maintain a uniform pore structure, guaranteeing consistent filtration performance and optimal metal quality.

- Ease of Installation: Designed for hassle-free setup and operation, our filters streamline the casting process, saving valuable time and resources for foundry operators.

- Proven Reliability: Backed by extensive research and development, our Zirconia Ceramic Filters have earned a reputation for reliability and excellence, trusted by leading foundries worldwide.

Related Products

Available in a wide range of refractory ceramic casting materials for your casting production.

Experience the Difference:

Join the ranks of foundries that have revolutionized their metal casting processes with Zirconia Ceramic Filters. Contact us today to discover how our premium filtration solutions can optimize your operations and elevate your casting quality to new heights. Unlock the potential of your foundry with Zirconia Ceramic Filters – the ultimate choice for precision casting excellence.