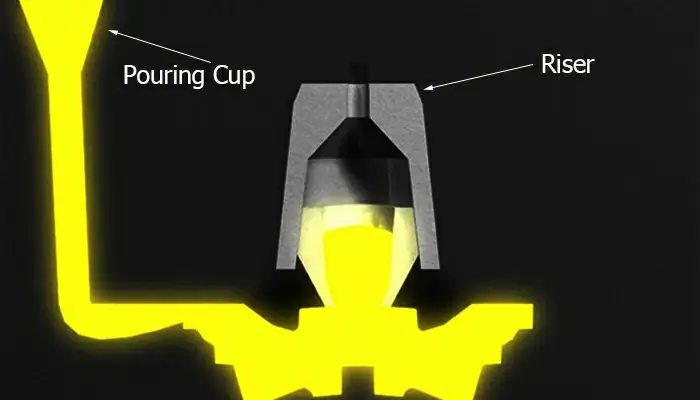

In metal casting, the production of defect-free and structurally sound components requires precise control of the solidification process. The riser (also known as a feeder) plays an indispensable role in achieving this objective. It serves as a reservoir of molten metal specifically designed to supply the casting as it cools and solidifies, thereby preventing the formation of internal defects such as shrinkage cavities, porosity, and other structural imperfections.

The Necessity of Risers: Understanding Metal Shrinkage

Metals undergo significant volumetric reduction during cooling and solidification. This natural behavior occurs in three distinct stages:

-

Liquid shrinkage as the metal cools from pouring temperature to its solidification point

-

Solidification shrinkage during the phase change from liquid to solid state

-

Solid-state contraction as the casting cools to ambient temperature

Without a supplemental source of molten metal to compensate for this volumetric loss, the casting develops internal voids that compromise mechanical properties, pressure integrity, and overall reliability.

Key Functions of Risers

Risers perform multiple essential functions in the casting process:

Primary Function: Feeding

-

Supplies molten metal to compensate for shrinkage throughout solidification

-

Maintains liquid metal longer than the casting through strategic design

-

Ensures continuous flow of material to fill potential voids

Secondary Functions:

-

Venting: Provides escape path for gases generated during pouring

-

Slag Trapping: Allows impurities to float away from critical casting areas

-

Process Indication: Enables visual confirmation of complete mold filling (open risers)

Design Principles for Effective Risers

Successful riser design incorporates several critical principles:

| Principle | Description | Importance |

|---|---|---|

| Delayed Solidification | Riser must solidify after the casting section it feeds | Ensures continuous metal supply during critical solidification phase |

| Adequate Metal Volume | Contains sufficient molten metal to meet shrinkage demands | Prevents premature exhaustion of feeding capability |

| Optimal Placement | Strategically positioned near casting hot spots | Provides effective feeding paths to critical areas |

| Thermal Management | Uses insulating materials or exothermic compounds | Maintains metal in liquid state longer, improving efficiency |

| Economic Optimization | Balances functionality with material usage | Maximizes yield while minimizing waste and recycling costs |

Types of Risers and Their Applications

Different casting scenarios require specific riser configurations:

| Type | Description | Advantages | Applications |

|---|---|---|---|

| Open Riser | Exposed to atmosphere | Excellent venting, visual monitoring | General sand castings |

| Blind Riser | Completely enclosed within mold | Superior thermal efficiency | Complex castings |

| Insulated Riser | Features insulating sleeves | Improved efficiency, smaller size | Ferrous castings |

| Exothermic Riser | Contains heat-generating materials | Maximum thermal performance | High-value castings |

Implementation and Economic Considerations

The practical application of risers involves both technical and economic factors. After solidification, the riser is removed during the fettling process through cutting, grinding, or knocking. While the riser metal is typically recycled, its design represents a balance between ensuring quality and minimizing material consumption.

Modern foundries employ advanced simulation software to:

-

Predict solidification patterns

-

Optimize riser placement and size

-

Maximize metal yield

-

Reduce trial-and-error methods

Conclusion: The Critical Role in Quality Assurance

Risers serve as fundamental safeguards against solidification defects in metal casting. Through careful design and implementation, they ensure that castings meet stringent quality standards across critical industries including automotive, aerospace, and heavy machinery. The proper understanding and application of riser technology represents the intersection of metallurgical science and practical engineering, enabling the production of high-integrity components that meet modern performance requirements.

The strategic use of risers, while representing additional material cost, ultimately proves cost-effective by preventing scrap, rework, and potential component failure in service. This makes risers not merely a technical requirement but a vital economic consideration in competitive manufacturing environments.