In the realm of metal casting, precision and efficiency are paramount. One essential component that plays a pivotal role in this process is the alumina ceramic foam filter. This porous ceramic filter is a cornerstone technology utilized across various industries, including aerospace, automotive, and renewable energy. Its impact on metal casting processes, particularly in the aerospace and wind turbine sectors, is profound and merits comprehensive analysis.

Understanding Porous Ceramic Filters:

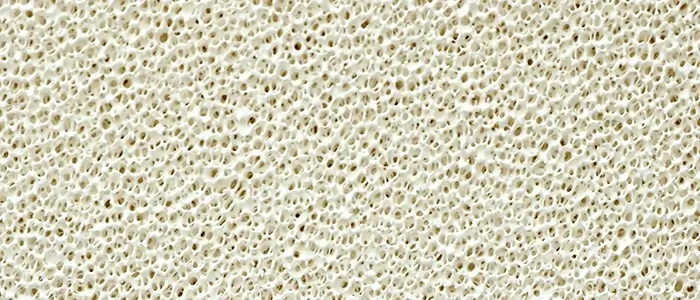

Porous ceramic filters serve as indispensable tools in the metal casting industry, where they facilitate the removal of impurities and enhance the quality of the final product. These filters, characterized by their intricate network of interconnected pores, effectively trap unwanted particles and ensure a smoother casting process. The impact of porosity on porous ceramic filters is profound, influencing factors such as filtration efficiency, flow rate, and structural integrity.

A Comprehensive Analysis of Porosity’s Impact:

The porosity of porous ceramic filters significantly affects their performance in metal casting applications. A higher porosity typically correlates with improved filtration efficiency, allowing for the retention of smaller particles and impurities. However, excessive porosity may compromise the structural integrity of the filter, leading to potential issues such as breakage or reduced lifespan. Achieving the optimal balance of porosity is, therefore, crucial in maximizing the effectiveness of these filters.

Porous Ceramics Examples and Materials:

Porous ceramics encompass a diverse range of materials tailored to suit specific casting requirements. Examples include alumina, silicon carbide, and zirconia-based ceramics, each offering unique properties suited to various applications. These materials exhibit high thermal stability, chemical resistance, and mechanical strength, making them ideal candidates for demanding casting environments.

Alumina Ceramic Foam Filter in Metal Casting:

Among porous ceramic filters, alumina ceramic foam filters stand out for their exceptional performance and versatility. These filters, composed of high-purity alumina, feature a three-dimensional network of interconnected pores that efficiently capture impurities during the casting process. Whether casting aluminum ingots, rods, or large aerospace components, alumina ceramic foam filters play a critical role in ensuring the integrity and quality of the final product.

Porous Ceramic: Applications in the Aerospace Industry:

In the aerospace field, where precision and reliability are non-negotiable, alumina ceramic foam filters find extensive use in the casting of critical components. From turbine blades to rocket boosters, these filters help maintain the stringent quality standards required for aerospace applications. Their ability to remove impurities and enhance metal flow contributes to the production of flawless components essential for safe and efficient aerospace operations.

Advancements in Wind Turbine Blade Manufacturing:

The wind energy sector relies on large aluminum castings for the production of turbine components, including blades. Alumina ceramic foam filters play a vital role in this process, ensuring the integrity and quality of castings subjected to extreme operational conditions. By eliminating defects and enhancing material properties, these filters contribute to the efficiency and longevity of wind turbines, driving advancements in renewable energy technology.

Conclusion:

In conclusion, alumina ceramic basin foam filters represent a cornerstone technology in the realm of metal casting, offering unparalleled precision and efficiency. Their impact on various industries, including aerospace and renewable energy, is profound, shaping the production of critical components with unmatched reliability. Through a comprehensive analysis of porosity and material properties, these filters continue to push the boundaries of innovation, facilitating the creation of high-quality castings essential for modern industrial applications.