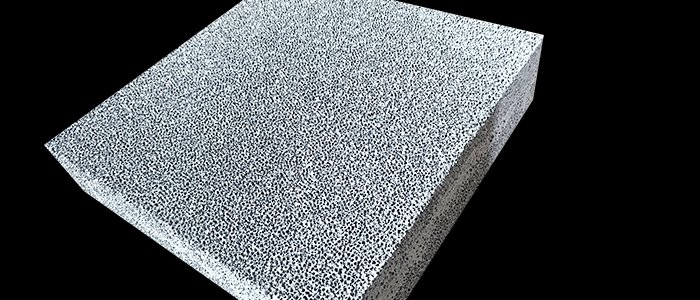

Porous ceramics are a class of ceramic materials that possess pores or voids within their internal structure. These pores can be either closed or open, and they can be of varying sizes and shapes. This unique property of porous ceramics has led to their widespread use in various industries such as electronics, aerospace, medical, and environmental.

What are the different types of porous ceramics?

In this article, we will provide an overview of the different types of porous ceramics that are available today.

Silica-based Porous Ceramics

Silica-based porous ceramics are a widely used type of ceramic material known for their excellent thermal stability and chemical resistance. These ceramics can be fabricated using different methods such as sol-gel process, liquid phase casting, and extrusion. Silica-based ceramics are commonly used for filter applications, catalysis, adsorption, and chromatography.

Alumina-based Porous Ceramics

Alumina-based porous ceramics are commonly used in the electronics and biomedical field due to their high mechanical strength, biocompatibility, and electrical insulation properties. These ceramics can be fabricated using various methods such as slip casting, tape casting, and sol-gel process. Alumina-based ceramics are typically used for cutting tools, MEMS devices, and bone grafts.

Titania-based Porous Ceramics

Titania-based porous ceramics are considered to be one of the most versatile types of ceramics due to their unique properties such as photocatalysis, self-cleaning, and superhydrophilicity. These ceramics can be fabricated using methods such as sol-gel process, solid-state reaction, and hydrothermal synthesis. Titania-based ceramics are commonly used in the production of photocatalytic reactors, self-cleaning glass, and water purification systems.

Zirconia-based Porous Ceramics

Zirconia-based porous ceramics are known for their excellent mechanical properties, high resistance to wear and corrosion, and good biocompatibility. These ceramics can be fabricated using methods such as tape casting, sol-gel process, and freeze casting. Zirconia-based ceramics are commonly used in the production of dental implants, hip replacements, and other biomedical applications.

Carbon-based Porous Ceramics

Carbon-based porous ceramics are a unique type of ceramic that is derived from carbon precursors. These ceramics are known for their high thermal conductivity, low thermal expansion, and excellent mechanical strength. They can be fabricated using various methods such as polymer pyrolysis, freeze casting, and carbonization of templated materials. Carbon-based ceramics are used in various applications such as thermal management, energy storage, and adsorption.

In conclusion, the development of different types of porous ceramics has opened up a wide range of applications in various industries. Each type of ceramic has unique properties and can be fabricated using different methods. The choice of material and fabrication method depends on the specific application requirements. Porous ceramics offer excellent mechanical, thermal, and chemical properties that make them ideal for use in various fields ranging from electronics to biomedical.