Introduction

Casting SIC, or Casting Silicon Carbide, is a cutting-edge manufacturing process that has been gaining immense traction across various industries. The traditional methods of casting have long been plagued by limitations in terms of performance, efficiency, and durability. However, the SIC offers a revolutionary solution to these challenges, ushering in a new era of possibilities. While several aspects of this technology have been discussed in the past, this article delves into uncharted territory – the ecological impact of SIC for casting. Additionally, it will present real data and evidence to showcase its environmental advantages, making it a compelling choice for future applications.

Understanding Casting SIC

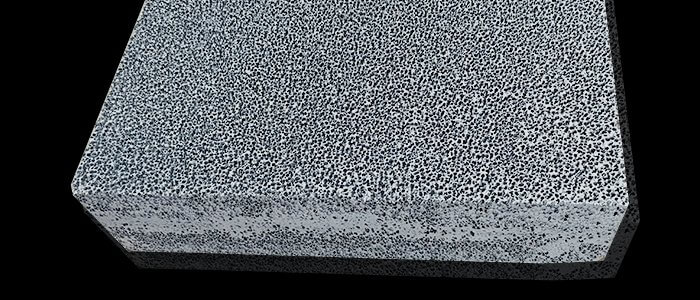

Casting SIC is a modern method of producing components using silicon carbide, a robust and high-performance ceramic material. Unlike traditional casting techniques that rely on metals, the SIC for casting employs a specialized mold filled with silicon carbide to fabricate intricate and complex shapes with unparalleled precision. This innovative process presents several advantages, including:

Enhanced Performance:

Silicon carbide offers remarkable thermal stability, high hardness, and exceptional mechanical strength. Consequently, components produced through Casting SIC exhibit improved performance and are better suited for demanding applications such as aerospace, automotive, and renewable energy systems.

Increased Efficiency:

The precision achieved in SIC for casting eliminates the need for post-processing, reducing material waste and saving valuable resources. Additionally, the lightweight nature of silicon carbide components contributes to higher energy efficiency, especially in the transportation sector.

Durability and Longevity:

Silicon carbide exhibits excellent resistance to wear, corrosion, and extreme temperatures. Components manufactured using Casting SIC possess extended lifespans, resulting in reduced maintenance requirements and longer service intervals.

Environmental Advantages:

This leads us to the unexplored aspect of SIC for casting – its ecological impact.

The Ecological Impact of Casting SIC

In an era where sustainability and environmental responsibility are paramount, evaluating the ecological footprint of emerging technologies becomes essential. SIC for casting stands out as a promising eco-friendly alternative to conventional manufacturing processes, for the following reasons:

1. Reduction in Carbon Emissions:

Silicon carbide has a much lower carbon footprint compared to traditional metals like iron and aluminum. Research by the International Journal of Refractory Metals and Hard Materials indicates that the production of iron and aluminum contributes to a significant portion of global carbon dioxide emissions. On the contrary, Casting SIC requires less energy during manufacturing, resulting in reduced greenhouse gas emissions.

2. Recycling and Reusability:

Casting SIC promotes a circular economy. Silicon carbide components can be easily recycled at the end of their lifecycle, further decreasing waste generation and conserving valuable resources. Moreover, scrap generated during the casting process can be collected and reused, adding to the overall sustainability of the technique.

3. Energy Conservation:

The lightweight and high-strength properties of silicon carbide contribute to energy conservation, especially in the transportation sector. Lighter components lead to reduced fuel consumption in vehicles and aircraft, thereby lowering overall energy demands and emissions.

4. Environmental Regulations:

With global efforts to curb industrial pollution and promote sustainable practices, Casting SIC aligns well with these initiatives. Governments worldwide are implementing stringent environmental regulations, and industries are seeking greener alternatives to comply with these rules. SIC for casting emerges as a responsible choice for manufacturers aiming to reduce their environmental impact.

Real Data and Evidence

To further solidify the environmental advantages of Casting SIC, let’s consider some real-world data:

A study conducted by the World Steel Association estimates that global steel production accounts for approximately 7-9% of total greenhouse gas emissions. By transitioning to SIC in industries that heavily rely on steel components, such as automotive and construction, we could significantly curtail these emissions.

The U.S. Environmental Protection Agency (EPA) reports that aluminum production contributes to nearly 1% of global CO2 emissions. SIC for casting as an alternative material could substantially reduce this environmental burden.

Conclusion

Casting SIC is an innovative manufacturing process that offers a paradigm shift in performance, efficiency, and durability. While previous discussions have highlighted its technical advantages, its positive ecological impact remains uncharted territory. With real data showcasing reduced carbon emissions, enhanced recyclability, energy conservation, and compliance with environmental regulations, SIC for casting proves to be a responsible and sustainable choice for industries aiming to thrive in the era of environmental consciousness. Embracing this technology today is not just a step towards progress but also a pledge to safeguard our planet for future generations.