The filtration efficiency of Silicon carbide ceramic foam filters is one of the key factors that make them a preferred choice in various industries. Ceramic foam filters are designed to effectively remove impurities and contaminants from liquids and gases, ensuring cleaner and purer end products. Let’s explore the factors that contribute to their high filtration efficiency.

Filtration Efficiency of Silicon Carbide Ceramic Foam Filters:

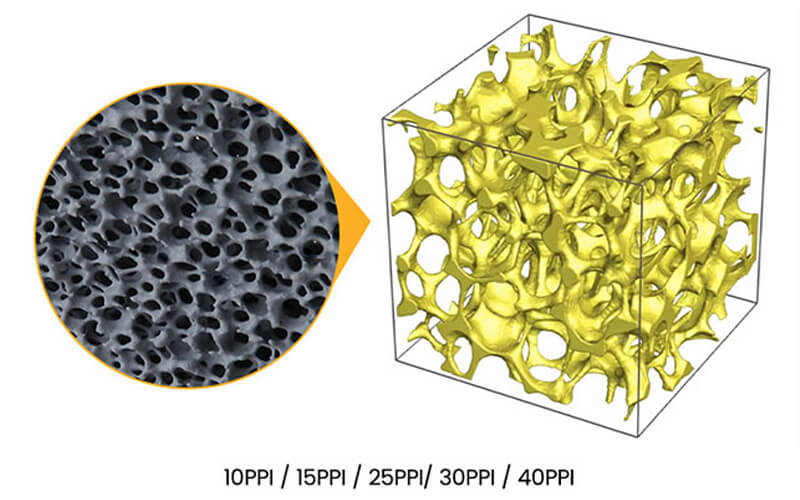

Silicon carbide filters excel in achieving remarkable filtration efficiency. The combination of their high porosity and small pore sizes allows for the efficient removal of impurities, even at the microscopic level. These filters can effectively trap contaminants, such as suspended solids, bacteria, and even certain organic compounds, ensuring the purity and quality of the filtrate.

The filtration efficiency of silicon carbide filters is further enhanced by their excellent chemical resistance and thermal stability. They can withstand aggressive chemicals and high temperatures without compromising their filtration performance, making them suitable for a wide range of applications across various industries.

Applications in Different Industries:

The exceptional filtration capacity of silicon carbide filters has found applications in diverse industries.

Water Treatment:

Silicon carbide filters are extensively used in water treatment processes to remove suspended solids, bacteria, and other contaminants. Their high filtration efficiency ensures clean and safe drinking water, as well as the purification of industrial process water.

Metal Casting:

In the metal casting industry, silicon carbide filters are employed to remove impurities and solid particles from molten metals. Their ability to withstand high temperatures and optimize metal flow control significantly improves casting quality and reduces defects, resulting in superior finished products.

Chemical Processing:

Silicon carbide filters are also utilized in chemical processing plants to capture fine particles, catalysts, and sediments. They help maintain the purity of chemicals, prevent equipment damage, and enhance overall process efficiency.

Pharmaceutical and Food Industries:

These filters play a critical role in pharmaceutical and food production, ensuring the removal of microorganisms, contaminants, and unwanted particles from liquids and gases. The high filtration capacity of silicon carbide filters helps maintain product integrity and safety.

Conclusion:

Silicon carbide filters have revolutionized the filtration industry with their exceptional filtration capacity. The unique pore structure and size of these filters allow for efficient removal of impurities and contaminants, ensuring clean and purified substances across various industries. From water treatment to metal casting, the versatility and reliability of silicon carbide filters have made them indispensable in numerous applications. As technology continues to advance, these innovative filters will likely play an even more significant role in meeting the growing demand for efficient and sustainable filtration solutions.