Introduction

In the world of mechanical equipment, maintaining optimal performance and longevity is a constant challenge. One of the most significant threats to the efficient operation of these machines is the presence of impurities. These impurities, such as dirt, debris, and contaminants, can wreak havoc on mechanical components, leading to increased maintenance costs and reduced lifespan. Enter silicon carbide (SiC), a material that has emerged as a silent hero in the battle against impurities.

Understanding Silicon Carbide

Silicon carbide, often referred to as SiC, is a unique compound comprised of silicon (Si) and carbon (C). It is renowned for its remarkable properties, including high hardness, exceptional thermal conductivity, and excellent chemical resistance. These qualities make SiC an ideal candidate for various industrial applications, including the absorption of impurities in mechanical equipment.

![]()

How Silicon Carbide Absorbs Impurities

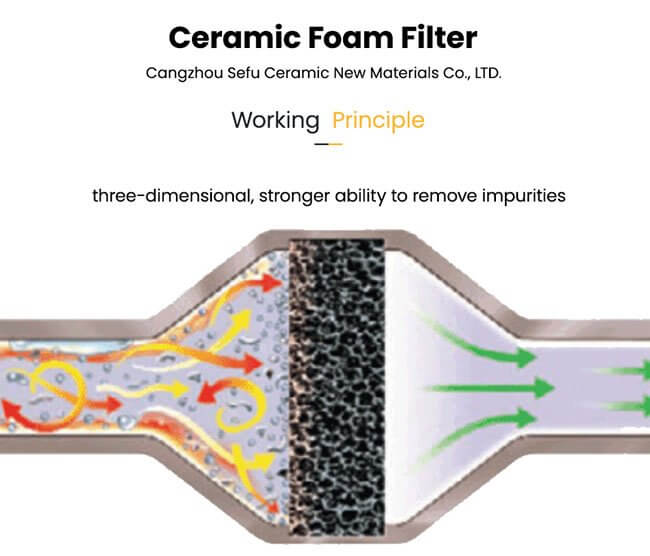

The ability of silicon carbide to absorb impurities lies in its porous structure. SiC materials are often manufactured in the form of porous ceramics or filters. These materials have a high surface area with interconnected pores of controlled size. When used as a filter or absorbent, SiC’s porous structure allows it to trap and retain impurities effectively.

Here’s how the process works:

Filtration: Mechanical equipment typically incorporates SiC filters or components designed to capture impurities as the fluid (liquid or gas) passes through. The porous structure of SiC allows the fluid to pass through while trapping impurities within its pores.

Adsorption: Silicon carbide has a strong adsorption capacity due to its surface chemistry. Contaminants are attracted to the SiC surface and adhere to it. This phenomenon is especially pronounced in the presence of organic compounds, which are common impurities in many industrial processes.

Chemical Resistance: SiC’s chemical resistance ensures that it remains stable even when exposed to aggressive chemicals or high-temperature environments. This makes it a reliable choice for absorbing impurities in various industrial settings.

Why Silicon Carbide is Chosen as a Material for Absorbing Impurities

High Hardness: SiC is renowned for its exceptional hardness, which makes it highly durable and resistant to wear. This property ensures that SiC components can withstand the abrasive nature of many impurities without degrading over time.

Temperature Resistance: Silicon carbide can operate at extremely high temperatures, which is essential in applications where hot gases or fluids must be filtered or purified. Its thermal stability ensures that it maintains its performance even in harsh environments.

Chemical Inertness: SiC is highly chemically inert, meaning it does not react with most chemicals. This property allows it to maintain its integrity when exposed to a wide range of corrosive substances, making it ideal for absorbing impurities in chemical and petrochemical processes.

Longevity: SiC components have a long service life, reducing the need for frequent replacements and maintenance. This not only saves costs but also minimizes downtime in industrial processes.

Conclusion

Silicon carbide’s unique combination of properties, including high hardness, temperature resistance, chemical inertness, and porous structure, makes it an exceptional material for absorbing impurities in mechanical equipment. Whether used as a filter, adsorbent, or component within industrial processes, SiC plays a crucial role in maintaining the efficiency and reliability of machinery. As technology continues to advance, silicon carbide’s role in the battle against impurities will likely become even more prominent, ensuring the smooth operation of various industrial applications.

The term “silicon carbide ceramic foam filter” represents a specific application of silicon carbide (SiC) that is widely recognized as one of the most outstanding and versatile uses of this remarkable material. There are several reasons why silicon carbide ceramic foam filters are considered prominent representatives of SiC applications:

- Exceptional Porosity

- Metallurgical Applications

- High-Temperature Resistance

- Chemical Inertness

- Improved Product Quality

- Reduced Waste and Costs

- Wide Range of Sizes and Shapes

- Environmental Benefits

In summary, silicon carbide ceramic foam filters are outstanding representatives of SiC applications due to their unique combination of properties, including high porosity, high-temperature resistance, chemical inertness, and suitability for metallurgical processes. Their ability to enhance product quality, reduce waste, and contribute to environmental sustainability has solidified their position as an essential component in various industrial applications, particularly in the metal casting industry.