Exploring Porous Ceramic Filtration in Metal Casting

In the world of metal casting, using advanced materials such as ceramic porosity is essential for maintaining the quality and efficiency of the final product. Among these materials, the porous ceramic filter is a key component, aiding in removing impurities and contaminants from molten metal to ensure the production of top-notch castings. SEFU Company, known for its expertise in ceramics porosity and filtration technology, offers a variety of porous ceramic materials tailored to meet the specific needs of the casting industry.

Understanding Porous Ceramic Filtration

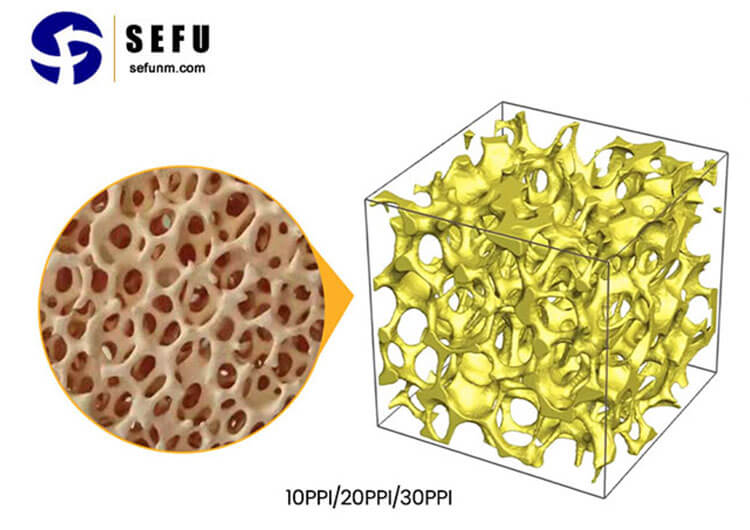

Porous ceramic materials are designed with interconnected pores that allow fluids to pass through while trapping particles and contaminants. In metal casting, porous ceramic filters serve as highly effective filtration media, using their inherent porosity to capture impurities from molten metal during the casting process. SEFU’s ceramic filters are carefully engineered to optimize porosity and pore size distribution, enabling efficient filtration while minimizing flow resistance.

Performance of Porous Ceramic Filter Materials

Several factors influence the performance of porous ceramic filter materials, including porosity, pore size distribution, and thermal shock resistance. SEFU’s ceramic filter materials excel in these areas, offering high porosity to facilitate efficient filtration and uniform pore size distribution to ensure consistent performance across various casting applications. Additionally, the exceptional thermal shock resistance of SEFU’s porous ceramic materials allows them to withstand the extreme temperature fluctuations encountered during metal casting processes, ensuring long-lasting reliability and durability.

Characteristics of Porous Ceramic Filter Materials

Porous ceramic filter materials possess unique characteristics that make them ideal for metal casting applications. The ceramics porosity of SEFU’s ceramic filters enables the efficient removal of impurities from molten metal, resulting in superior-quality castings. Furthermore, the uniform pore size distribution ensures consistent filtration performance, while the materials’ thermal shock resistance enables them to endure the demanding conditions of the casting process. With these exceptional characteristics, SEFU’s ceramic filter materials offer unparalleled performance and reliability, making them indispensable components in the metal casting industry.

Conclusion

In conclusion, porous ceramic filtration plays a crucial role in maintaining the quality and integrity of cast metal products. SEFU Company’s expertise in porous ceramic materials and filtration technology establishes it as a reliable provider of high-quality porous ceramic filters for the casting industry. With their superior performance and reliability, SEFU’s porous ceramic filter materials are the preferred choice for manufacturers striving to achieve optimal casting results.