Introduction:

Alumina ceramic foam filters have become indispensable tools in various industries, particularly in foundries, metal casting, and molten metal filtration processes. These filters play a pivotal role in enhancing the quality of castings by effectively removing impurities and contaminants from molten metals. With their unique structure and exceptional filtration capabilities, alumina ceramic foam filters have revolutionized the casting industry.

Those filters are widely used in various industries, including foundries, metal casting, and molten metal filtration processes. These filters play a crucial role in removing impurities and enhancing the quality of the final product. In this essay, we will delve into the details of how to effectively use alumina ceramic foam filters and maximize their benefits.

Section 1: Understanding Alumina Ceramic Foam Filters

To begin with, let’s gain a comprehensive understanding of alumina ceramic foam filters. These filters are made of a porous ceramic material composed primarily of alumina. The unique structure of these filters allows them to trap and remove impurities from molten metal, such as slag, oxide inclusions, and non-metallic particles.

Section 2: Preparing for Filtration

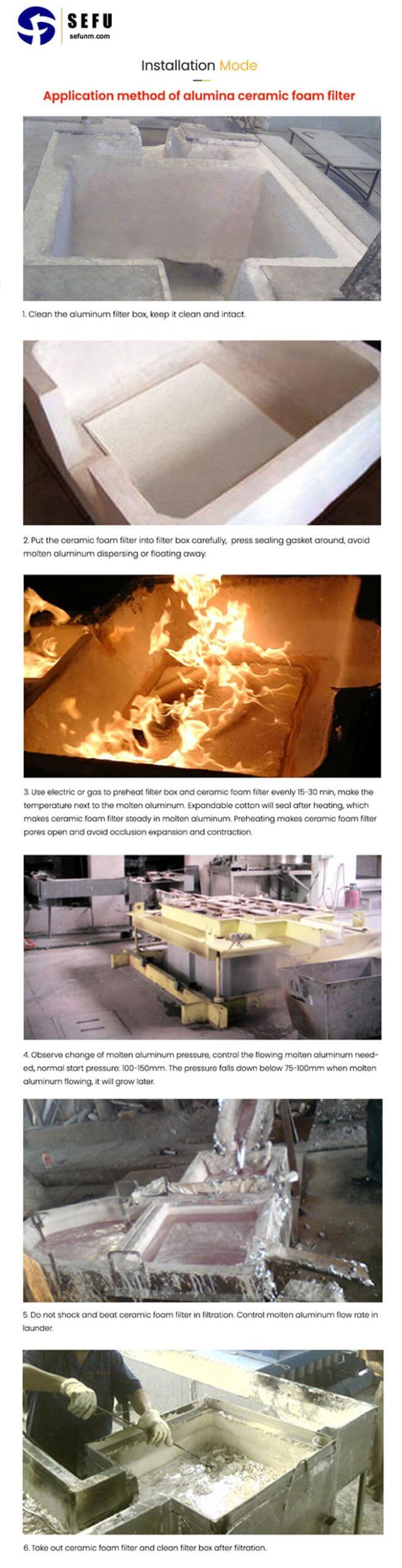

Before using alumina ceramic foam filters, proper preparation is essential. Here are the steps involved:

- Selection: Choose the appropriate alumina ceramic foam filter based on the type of metal being cast, its temperature, and the specific application requirements. Filters come in various sizes, shapes, and pore sizes to accommodate different casting processes.

- Cleaning: Clean the filter to remove any dust or contaminants that may affect its efficiency. Ensure the filter is handled with care to prevent damage.

- Preheating: Preheat the filter to match the temperature of the molten metal. This step helps to minimize thermal shock when the filter comes into contact with the hot metal.

Section 3: Placing the Filter

Now that the preparation is complete, it’s time to place the alumina ceramic foam filter correctly. Follow these guidelines:

- Positioning: Position the filter in the gating system of the mold where the metal enters. The filter should be placed in a way that allows the molten metal to flow through it uniformly.

- Orientation: Ensure that the filter is properly aligned to prevent any bypass of molten metal. The arrows marked on the filter can guide you in aligning it correctly.

- Support: Use appropriate supports to secure the filter in its position. This prevents any displacement during the casting process.

Section 4: Filtration Process

Now, let’s explore the filtration process itself and the factors to consider:

- Flow Rate: Maintain an optimal flow rate to ensure efficient filtration. A high flow rate can lead to turbulence and reduce filtration effectiveness, while a low flow rate can cause premature clogging.

- Avoiding Splashing: Take precautions to prevent splashing or excessive agitation of the molten metal, as this can disturb the filtration process and lead to re-entrainment of impurities.

- Monitoring: Regularly monitor the condition of the filter during the casting process. Look for signs of clogging or breakthrough, such as reduced flow or excessive pressure drop. Replace the filter if necessary to maintain the desired filtration quality.

Section 5: Post-Filtration Considerations

Once the casting process is complete, there are a few post-filtration considerations to keep in mind:

- Filter Removal: After the casting has solidified, remove the alumina ceramic foam filter from the gating system. Handle it with care to avoid any damage.

- Inspection: Examine the filter after use to assess its condition and identify any signs of wear or damage. This evaluation helps determine if the filter requires maintenance or replacement.

- Disposal: Properly dispose of used filters in accordance with local regulations and environmental guidelines. Recycling or reusing the filters, if possible, is an environmentally friendly option.

Section 6: Maintenance and Storage

To ensure the longevity and efficiency of alumina ceramic foam filters, proper maintenance and storage practices are essential:

- Cleaning: After use, clean the filters thoroughly to remove any residual metals or contaminants. Use appropriate cleaning agents and techniques recommended by the manufacturer. Avoid abrasive materials that may damage the filter structure.

- Drying: Allow the filters to dry completely before storage. Moisture can lead to the growth of mold or deterioration of the filter material.

- Storage Conditions: Store the filters in a dry and clean environment, away from direct sunlight and extreme temperatures. Consider using a designated storage area or container to protect the filters from physical damage.

- Regular Inspections: Periodically inspect stored filters to ensure they remain in good condition. Look for signs of deterioration, such as cracks, breakage, or degradation of the filter structure. Replace any damaged filters before using them.

Section 7: Advantages

Alumina ceramic foam filters offer several advantages in the casting process:

- Improved Quality: These filters effectively remove impurities, resulting in castings with higher quality and improved mechanical properties.

- Enhanced Surface Finish: The use of alumina ceramic foam filters helps reduce defects such as inclusions and surface roughness, leading to a smoother and more aesthetically pleasing surface finish.

- Versatility: Alumina ceramic foam filters can be used with various metals, including aluminum, steel, copper alloys, and more. Their versatility makes them suitable for a wide range of casting applications.

Alumina ceramic foam filters are essential tools for achieving high-quality castings. By understanding their properties, following proper usage guidelines, and implementing maintenance practices, you can harness the benefits they offer. Remember to select the appropriate filter, prepare it adequately, position it correctly, and monitor the filtration process. With careful attention to detail, alumina ceramic foam filters can significantly enhance the efficiency and quality of your casting operations.

Section 8: Troubleshooting and Common Challenges

While using alumina ceramic foam filters, you may encounter some challenges. Here are a few troubleshooting tips to overcome common issues:

Clogging: If you notice a significant reduction in flow rate or pressure drops across the filter, it may indicate clogging. To address this, inspect the filter for blockages and clean it if necessary. If cleaning is ineffective, replace the filter to ensure proper filtration.

Filter Breakage: Occasionally, filters may break during handling or casting. To prevent this, handle the filters with care, avoid excessive force, and ensure proper support and alignment during installation. If a filter breaks, remove all fragments from the casting and replace them with a new one.

Incomplete Filtration: If impurities still appear in the castings despite using alumina ceramic foam filters, reassess the filter’s size, pore structure, or placement. Make adjustments accordingly to optimize the filtration process.

Section 9: Safety Considerations

When using alumina ceramic foam filters, it is important to prioritize safety. Follow these safety guidelines:

Personal Protective Equipment (PPE): Wear appropriate PPE, including heat-resistant gloves, safety glasses, and heat-resistant clothing, to protect against potential burns or injuries during handling and casting operations.

Hot Metal Handling: Take caution when working with molten metal. Ensure proper training and use suitable tools and equipment for handling hot metal to minimize the risk of burns or accidents.

Fire Safety: Be mindful of fire hazards associated with casting operations. Follow fire safety protocols, have fire extinguishing equipment nearby, and ensure a well-ventilated casting area to mitigate the risk of fire incidents.

Material Safety Data Sheets (MSDS): Familiarize yourself with the MSDS provided by the manufacturer for the alumina ceramic foam filters. Understand the handling, storage, and disposal recommendations to ensure safe practices.

Conclusion:

The effective use of alumina ceramic foam filters in metal casting processes can significantly improve the quality and integrity of castings. By understanding their properties, following proper procedures for their use, troubleshooting common issues, and prioritizing safety, you can maximize the benefits of these filters. Remember to consider maintenance, storage, and safety guidelines to ensure the longevity of the filters and create a safe working environment. With these considerations in mind, alumina ceramic foam filters can be powerful tools for achieving high-quality castings.

Alumina ceramic foam filters are invaluable tools in the metal casting industry. By understanding their properties and following the proper procedures for their use, you can maximize their effectiveness in removing impurities and improving the quality of your castings. Remember the key steps: understand the filters, prepare them adequately, position them correctly, and ensure a smooth filtration process. By adhering to these guidelines, you can achieve optimal results in your casting operations.