FOUNDRY THERMOCOUPLE

SEFU has provided temperature measurement solutions to the foundry and molten metals industry, particularly in iron and steel plants.

- High precision

- Rapid response

- Reliability

- Stability

- Easily measurable

- Technical Parameters

- Factory Pictures

| Graduation | Successful Test Rate | Response Time | Accurate Deree (1554℃) | Upper of Measure | Protective Cap | Material |

| S | ≥98% | 2s-5s | 1.5℃ | 1710℃ | Paper Cap | Paper |

| R | 1.5℃ | 1710℃ | Metal Cap | Al | ||

| B | 1.5℃ | 1800℃ | Cu |

SEFU Foundry Thermocouple is a temperature sensor that can measure the temperature in a wide range. The foundry thermocouple is mainly composed of a thermometer tip and protective paper tubes.

SEFU Foundry Thermocouple Application

SEFU Foundry Thermocouple is used to measure the molten metal temperature accurately. It can be used in molten steel and molten iron. Its measurement error is ≤±3℃. Accurate temperature measurement is essential to controlling and analyzing the temperature of molten metal.

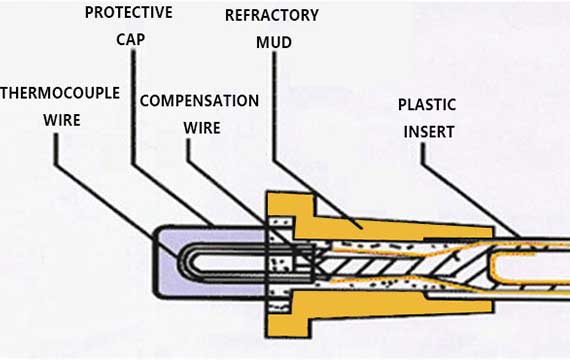

Structure of Foundry Thermocouple

The foundry thermocouple is mainly composed of a thermometer tip and a protective paper tube. The thermocouple tip is composed of even wire, compensation wire, bracket, small paper tube, quartz, anti-slag cap, etc.

FAQs About the Foundry Thermocouple

Accurate temperature measurement is essential to controlling and analyzing the temperature of molten metal. All the parts and components are put into the mud head and glued into a whole with refractory filler and cannot be disassembled. It has the sensing type also the foundry thermocouples and various other temperature devices.

The Thermocouples are protected with a paper tube for use with a lance tube, this product is mainly used to measure the temperature of molten metals in foundries and steel mills.

- Effective temperature measurement.

- High precision.

- Easily measurable.

- Operational safety.

- More using time.