The foundry industry plays a vital role in the growth and development of various other industries globally. Foundries are responsible for molding and casting various metal parts, which are used in diverse fields such as construction, automobiles, aviation, and many others. The foundry industry thrives on innovation and technology, and Poland is no exception. The country is rapidly establishing itself as a hub for the foundry industry through continuous innovation and the adoption of new technology.

The foundry industry in Poland has been growing at a significant rate in recent years, with rising foreign investments, government initiatives, and strong economic growth. The market is highly competitive, with many players, both domestic and international, wooing customers with improved services, high-quality products, and price competitiveness.

In this article, we shall delve into the market analysis of the foundry industry in Poland, including its strengths, weaknesses, opportunities, and threats. Additionally, we shall provide an application case of the Sic Ceramic Foam Filter, one of the popular tools in the foundry industry, and explore its practical applications in a Polish foundry.

Market Analysis of the Foundry Industry in Poland

Strengths

One of the main strengths of the foundry industry in Poland is its strategic location. Poland is situated at the crossroads of Europe, which makes it easily accessible to consumers, suppliers, and distributors. Additionally, Poland has access to a large pool of human resources, which provides a skilled workforce, necessary for the industry’s growth.

Poland is also an attractive destination for foreign direct investment, which is a massive boost to the foundry industry. The government has set up various initiatives and policies aimed at attracting more investments in this sector. The low corporate tax rates and streamlined bureaucratic processes make it easier for investors to set up factories and production facilities in Poland.

Lastly, the foundry industry in Poland has adopted the latest technologies and innovations. Companies are investing heavily in research and development to enhance their production efficiency, improve product quality, and reduce the environmental impact of their operations.

Weaknesses

However, the foundry industry in Poland also has a few weaknesses, chief among them being the shortage of raw materials. Poland is not rich in minerals, and foundries often have to import raw materials and alloys from other countries. This dependency on other countries for raw materials, which are susceptible to price fluctuations, makes it challenging to remain competitive.

Another weakness is the industry’s dependence on a few select markets. The automotive and construction industries are among the largest consumers of metal products. Exporting countries like Germany and Italy, which are highly dependent on these markets, can affect the market’s stability in Poland.

Opportunities

Poland has a vast domestic market, with various industries and sectors still developing. The construction and automotive sectors are among the fastest-growing in the country. The development of residential and commercial properties continues to create a demand for metal parts used in fittings, piping systems, etc. Additionally, foreign investments have also opened up new markets, creating opportunities for foundries to expand their operations globally.

New technologies like 3D printing and robotics present innovative ways of improving efficiency and enhancing the quality of products. The use of green or sustainable materials, which have less environmental impact, presents an opportunity for foundries to increase their brand value and appeal to eco-conscious consumers.

Threats

One of the significant threats to the foundry industry in Poland is the increasing competition from other countries, particularly China and India. These countries have massive and growing foundry markets, which makes them more competitive in terms of pricing, production efficiency, and raw material sourcing.

Moreover, the decrease in demand from the EU’s largest economies, Germany and Italy, due to the current economic challenges, presents a challenge to Poland’s foundry industry. The pandemic also hit the industry hard, with many operations shutting down temporarily due to reduced demand and supply disruption.

Application of Sic Ceramic Foam Filter in a Polish Foundry

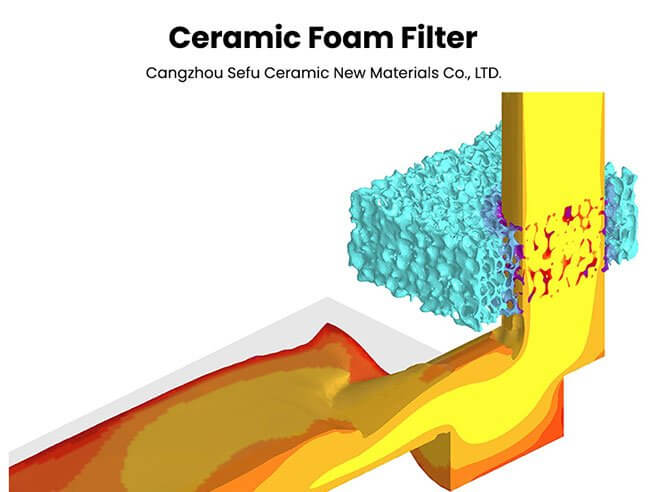

The Sic Ceramic Foam Filter is a sophisticated tool used in the foundry industry to improve the casting process’s quality and efficiency. The filter is used in the casting of aluminum and other non-ferrous metals, to remove impurities like dross and slag from the molten metal.

The ceramic foam filter is made of silicon carbine, an advanced ceramic material that provides excellent filtering properties. It possesses high-temperature resistance, chemical resistance, and good mechanical properties, making it ideal for the foundry industry.

One application case of the Sic Ceramic Foam Filter in a Polish foundry is in the production of automobile parts. Automobile parts manufacturers demand high-quality metal components, free of defects, and the Sic Ceramic Foam Filter is an ideal tool to ensure the production of high-quality parts.

Additionally, the foundry industry in Poland has been applying the Sic Ceramic Foam Filter to meet the country’s strict environmental regulations and sustainability goals. The filter reduces the discharge of pollutants, enhances energy efficiency, and minimizes the carbon footprint of the foundry.

Conclusion

The foundry industry in Poland offers multiple opportunities thanks to its strategic location, skilled labor force, and government initiatives aimed at attracting foreign investments. Despite the challenges, the industry is continuously adopting innovative technology to enhance efficiency, product quality, and reduce environmental impacts.

The Sic Ceramic Foam Filter presents a viable solution for foundries looking to improve their operations’ quality and sustainability. Its applications in the production of automobile parts and meeting environmental regulations attest to its versatility and benefits in the foundry industry.

In conclusion, the foundry industry in Poland is poised for continued growth and expansion, as long as it can navigate the stiff competition, price fluctuations, and remain abreast of technological advancements.