Introduction

In the world of metallurgy and foundry, innovation plays a pivotal role in improving the quality and performance of cast iron products. One such innovation that has revolutionized the casting process is the Silicon Carbide Ceramic Foam Filter (SIC ceramic foam filter). This article explores the significant role of SIC ceramic foam filters in the cast iron industry, while also sharing an inspiring story of how SEFU company’s commitment to customer satisfaction led to a successful partnership.

The Role of SIC Ceramic Foam Filters in Cast Iron

Cast iron has been a cornerstone material in numerous industries due to its durability and cost-effectiveness. However, achieving high-quality cast iron products often requires meticulous attention to detail during the casting process. One of the most critical aspects is the removal of impurities and inclusions from the molten metal before it solidifies. This is where SIC ceramic foam filters come into play.

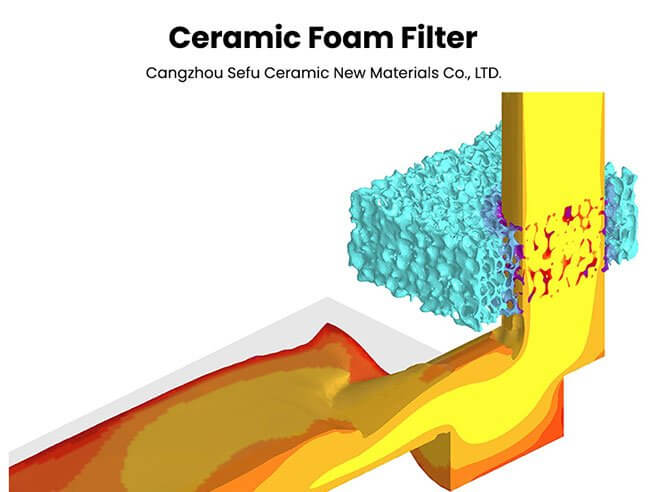

SIC ceramic foam filters are a cutting-edge solution designed to enhance the quality of cast iron by effectively removing impurities such as oxides, slag, and non-metallic inclusions from the molten metal. These filters are made from silicon carbide, a highly durable and heat-resistant material, and boast a porous foam-like structure. This unique structure allows the filters to trap and retain impurities while allowing the clean molten metal to pass through smoothly.

The use of SIC ceramic foam filters in the casting process offers several benefits:

Improved Casting Quality: SIC ceramic foam filters enhance the quality of cast iron products by ensuring a cleaner and more homogeneous metal composition, resulting in reduced defects and improved mechanical properties.

Increased Efficiency: These filters provide consistent and reliable filtration, reducing the need for costly rework and improving overall production efficiency.

Cost Savings: By minimizing defects and improving yield rates, SIC ceramic filters help foundries save on materials and resources, making them a cost-effective investment.

Environmental Benefits: The use of SIC foam filters contributes to a cleaner and more sustainable casting process, reducing waste and environmental impact.

The SEFU Company Story

A heartwarming story involving an Indian end customer illustrates the value and effectiveness of SIC ceramic foam filters in the casting industry. The customer, in search of a solution to improve their cast iron quality, approached SEFU, a renowned manufacturer of ceramic filtration products.

The customer expressed their desire for a new batch of samples for testing, with the intention of placing a significant order in the near future. However, the order quantity was substantially larger than previous sample requests. Understanding the customer’s needs and recognizing the potential for a long-term partnership, the sales manager at SEFU responded with a heartfelt message.

“Dear customer, I am very grateful to you for choosing us, but the order quantity you requested is really far beyond the range of sample costs that the company can afford, so the company really cannot provide free samples. However, in order to show the company’s sincerity, we are willing to give samples of ‘Silicon Carbide Ceramic Foam Filter’ free of charge.”

This genuine gesture of goodwill and commitment to customer satisfaction resonated with the Indian customer. They appreciated SEFU’s dedication to building a strong partnership and agreed to try the SIC ceramic foam filters as suggested.

After testing the product, the customer was not only satisfied but also impressed by the remarkable improvement in their cast iron quality. They recognized the value of SIC ceramic filters in their casting process and expressed their intention to place a substantial order in the future.

Conclusion

The story of SEFU company and its Indian customers highlights the pivotal role of SIC ceramic foam filters in the cast iron industry. These innovative filters have become indispensable in achieving higher-quality cast iron products by eliminating impurities and improving the overall casting process. SEFU’s commitment to customer satisfaction and willingness to go the extra mile led to a successful partnership and a brighter future for both parties, showcasing the remarkable potential of SIC ceramic filters in the foundry world.