Vietnam is a Southeast Asian country that is rapidly developing its manufacturing industry. The country is known for its low-cost labor and favorable investment policies, making it an attractive destination for investors. The aluminum casting market is one of the rapidly growing industries in Vietnam. According to a report by Mordor Intelligence, the aluminum casting market in Vietnam is expected to grow at a CAGR of 13.18% during the period 2021-2026. This growth is primarily due to the increasing demand for lightweight and energy-efficient materials in various industries such as automotive, construction, and aerospace. This article provides a comprehensive analysis of the aluminum casting market in Vietnam and cites an application case of the alumina ceramic foam filter in a Vietnamese aluminum factory.

Overview of the Aluminum Casting Market in Vietnam

Aluminum casting is the process of producing metal parts using aluminum alloys. Vietnam is currently the third-largest aluminum producer in Southeast Asia after Indonesia and Malaysia. The aluminum casting market in Vietnam is driven by the growth of various end-use industries such as automotive, aerospace, construction, and consumer goods. The automotive industry is the major consumer of aluminum castings, accounting for nearly 50% of the total demand. The construction industry is also a key growth driver, particularly in emerging economies in Southeast Asia.

The aluminum casting market in Vietnam is highly fragmented with the presence of numerous small and medium-sized enterprises (SMEs) operating in the country. These SMEs cater to the local demand for aluminum castings. However, the market is slowly maturing with the entry of large multinational corporations such as Toyota, Hyundai, and Samsung. These companies are investing in the aluminum casting industry in Vietnam to tap into the low-cost labor and favorable business environment in the country. Additionally, the Vietnamese government is keen on promoting foreign investment in the manufacturing sector by offering tax incentives, free land allocation, and other benefits.

Challenges in the Aluminum Casting Market in Vietnam

The aluminum casting market in Vietnam faces several challenges that restrain its growth potential. The first challenge is the availability of raw materials. Vietnam currently lacks the infrastructure to mine and supply bauxite, the primary raw material used in the production of aluminum. As a result, the country imports bauxite from other countries such as Australia and Guinea, increasing the production cost. Moreover, the limited availability of high-quality scrap metal restricts the growth of the recycling industry in Vietnam.

The second challenge is the lack of skilled labor. Despite having a large workforce, Vietnam has a shortage of skilled workers who are trained in the aluminum casting process. This shortage of skilled workers increases the production cost and can result in low-quality products. Therefore, the Vietnamese government is investing in vocational training programs to address this issue.

The third challenge is environmental pollution. The aluminum casting process is resource-intensive and generates a significant amount of waste and emissions. The Vietnamese government is implementing various regulations to address the environmental concerns associated with the aluminum casting industry. The regulations mandate the implementation of pollution control measures and the adoption of sustainable practices.

Application Case: Alumina Ceramic Foam Filter in a Vietnamese Aluminum Factory

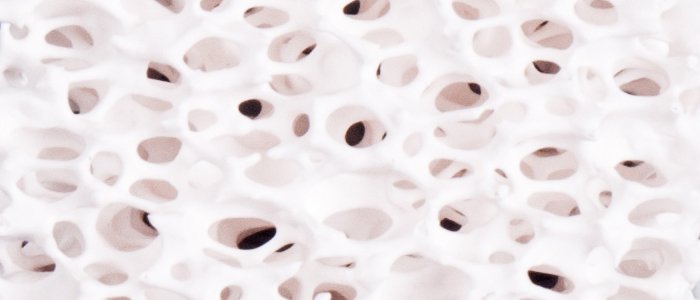

An alumina ceramic foam filter is a key component used in the aluminum casting process. The filter is used to remove impurities and improve the quality of the final product. The use of alumina ceramic foam filters in the aluminum casting process is gaining popularity in Vietnam due to its efficiency in removing impurities and the reduction of production costs. A case study of an aluminum factory in Vietnam demonstrates the use of alumina ceramic foam filters in the production process.

The aluminum factory in Vietnam was experiencing issues in the quality of their final products. The company was using traditional sand filters, which were not efficient in removing impurities. The company decided to switch to alumina ceramic foam filters to improve the quality of their products. The adoption of alumina ceramic foam filters resulted in an immediate improvement in the quality of the final products. The filters efficiently removed impurities, resulting in a more uniform and higher-quality product. Additionally, the use of alumina ceramic foam filters reduced the production cost by 20%, resulting in a significant increase in profitability for the company.

Conclusion

In conclusion, the aluminum casting market in Vietnam is expected to exhibit significant growth in the near future. The growth is driven by the increasing demand for aluminum castings in various end-use industries such as automotive, aerospace, construction, and consumer goods. However, the market faces several challenges such as the availability of raw materials, skilled labor, and environmental pollution. The Vietnamese government is taking proactive measures to address these issues and promote the growth of the aluminum casting industry. The adoption of alumina ceramic foam filters in the aluminum casting process is gaining popularity in Vietnam due to its efficiency in improving the quality of the final product and reducing production costs. The use of alumina ceramic foam filters in a Vietnamese aluminum factory resulted in an immediate improvement in product quality and increased profitability for the company.