Ceramic Filter for Steel Casting: Optimize Precision Casting

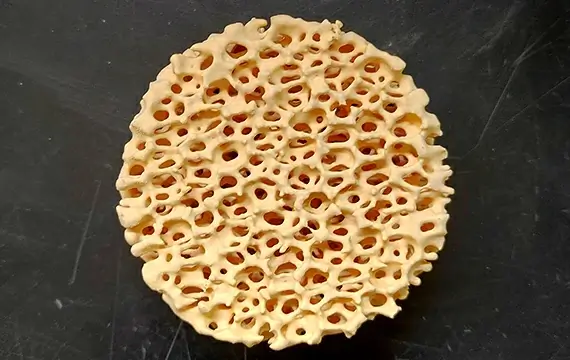

Explore the pinnacle of precision in steel casting with our Ceramic Filters engineered to withstand temperatures up to 1700°C. With pore sizes ranging from 10 to 40 PPI, our filters are meticulously crafted to optimize your steel casting process, ensuring impeccable quality and efficiency.

Applications

Our Zirconia Ceramic Foam Filters are ideal for various steel casting processes, including:

- Carbon Steel Casting

- Alloy Steel Casting

- Stainless Steel Casting

- And more…

- Product Parameters

| Pore Density (PPI) | 10–40 |

| Porosity (%) | 80-90 |

| Max Working Temperature (ºC) | 1700 |

| Bending Strength (Mpa) | 0.8-1.0 |

| Compressive Strength (Mpa) | 1.0-1.2 |

| Thermal Shock Resistance (times/1100-0ºC) | 6 |

Unparalleled Precision with Ceramic Filters for Steel Casting

Discover why our Ceramic Filters for Steel Casting are the epitome of excellence:

- High-Temperature Endurance: With a remarkable tolerance of up to 1700°C, our ceramic filters excel in the extreme heat of steel casting operations, maintaining structural integrity and filtration efficiency even under the most challenging conditions.

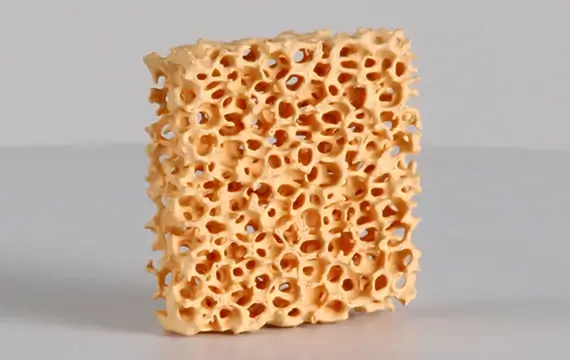

- Tailored Pore Sizes: Featuring pore sizes ranging from 10 to 40 PPI, our filters offer precise control over filtration, effectively removing impurities and contaminants from molten steel to produce flawless castings with superior surface finish and mechanical properties.

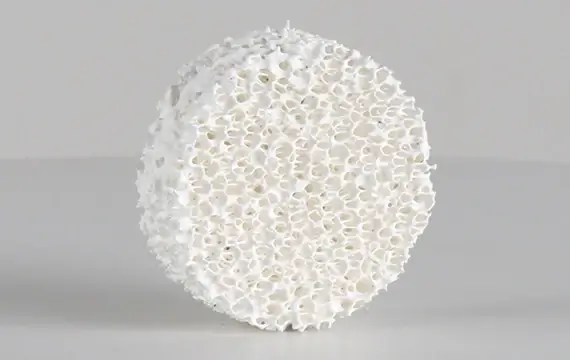

- Robust Construction: Crafted from premium ceramic materials, our filters boast exceptional mechanical strength and durability, ensuring reliable performance and longevity in demanding foundry environments.

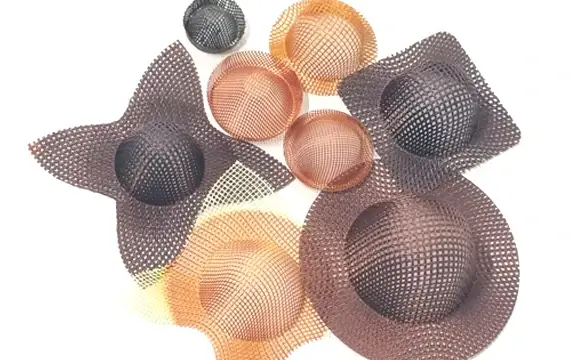

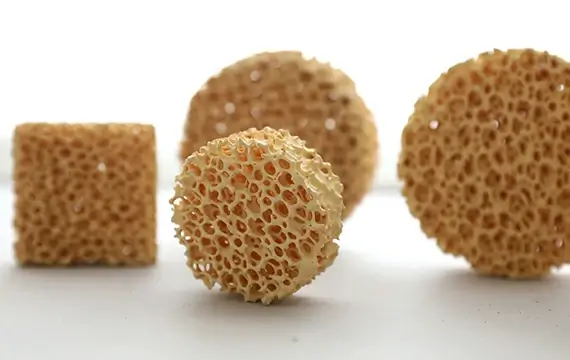

- Streamlined Integration: Designed for seamless integration into steel casting processes, our filters are available in various shapes, sizes, and configurations to meet the unique needs of steel foundries. Easy to install and maintain, they optimize workflow efficiency while minimizing downtime.

Key Features of Our Ceramic Filters for Steel Casting

- Precision Engineered Pore Structure: Achieve optimal filtration performance with our filters’ precisely controlled pore sizes, ensuring efficient removal of impurities and contaminants from molten steel for superior casting quality.

- Enhanced Mechanical Strength: Built to withstand the rigors of steel casting, our filters boast exceptional durability, ensuring reliable performance in demanding foundry environments.

- Wide Temperature Range: Withstanding temperatures up to 1700°C, our filters offer unmatched thermal stability, maintaining structural integrity and filtration efficiency throughout the steel casting process.

- Versatile Compatibility: Compatible with various steel casting processes, including carbon steel, alloy steel, and stainless steel casting, our filters provide consistent results and exceptional casting quality across different applications.

Related Products

Available in a wide range of refractory ceramic casting materials for your casting production.

Experience Precision Casting Excellence:

Elevate your steel casting process to new levels of precision and efficiency with our Ceramic Filters. Contact us today to discover how our premium filtration solutions can optimize your operations, improve casting quality, and drive productivity. Unleash the full potential of your steel foundry with Ceramic Filters for Steel Casting – the ultimate choice for precision casting excellence.