Alumina Ceramic Foam Filters - SEFU Ceramic

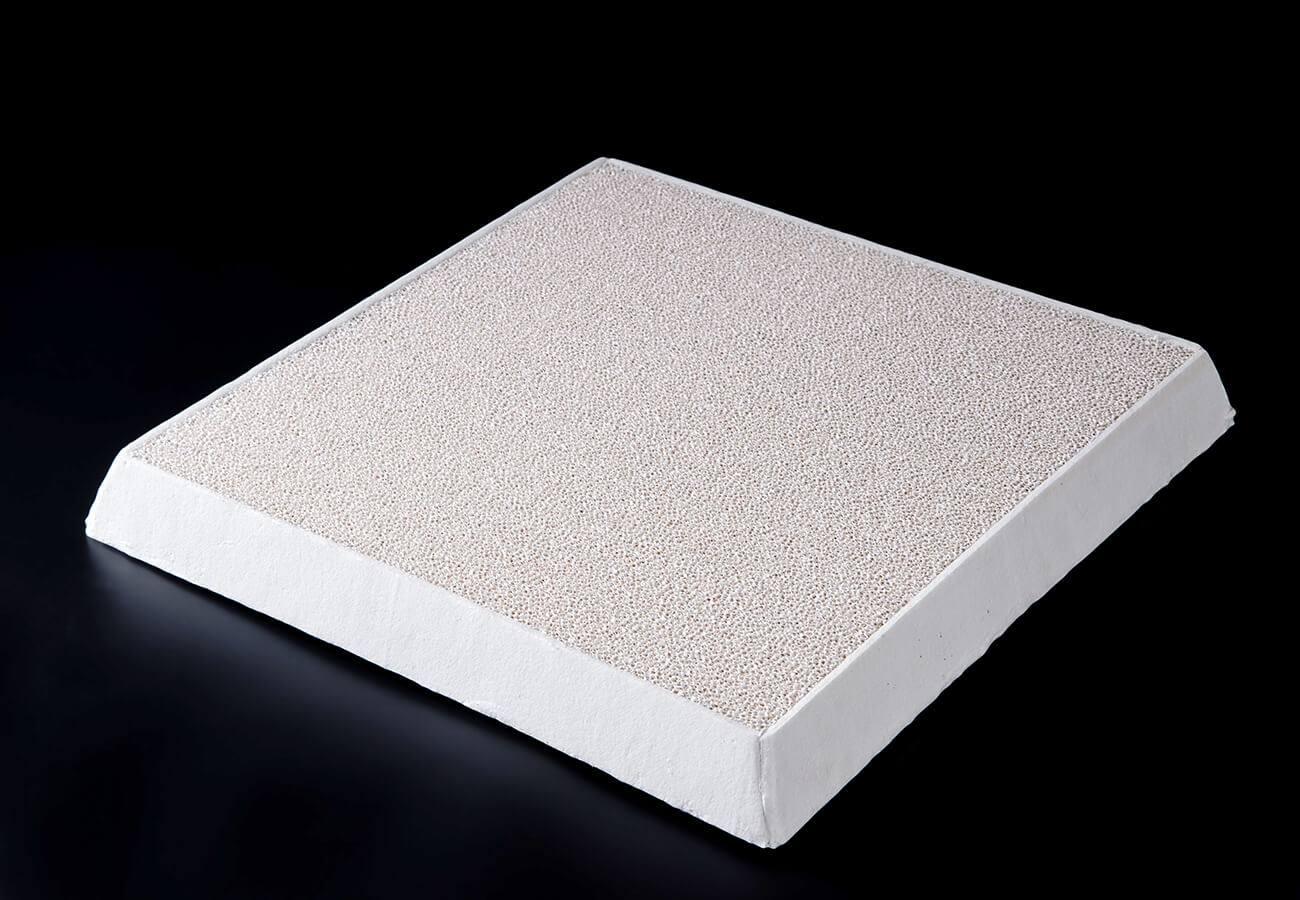

Alumina plates are large, lightweight, flat-shaped foam filters designed to reduce inclusions in aluminum casting by regulating the flow of molten metal. These filters have excellent chemical resilience, effectively resisting corrosive forces. Discover SEFU’s solution for impurity-free aluminum molding.

Description

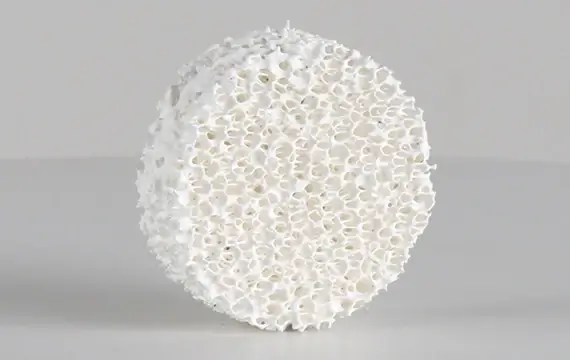

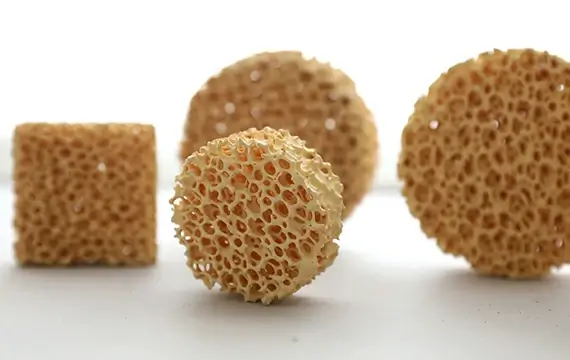

Al₂O₃-based foam filters are open-porous refractory materials, designed as rectangular aluminum plates with higher pore density. The larger surface area allows for more efficient refining of finer particles, making these filters particularly suitable for high-flow-rate applications in aluminum and alloy filtration. SEFU has developed these ceramic plate filters in various sizes, ranging from 7 to 26 inches, to accommodate a wide range of applications.

- Product Parameters

| Pore Density (PPI) | 10–60 |

| Porosity (%) | 80-90 |

| Max Working Temperature (ºC) | 1200 |

| Bending Strength (Mpa) | 0.8-1.0 |

| Compressive Strength (Mpa) | 1.0-1.2 |

| Thermal Shock Resistance (times/1100-0ºC) | 6 |

Advantages of SEFU’s Al₂O₃-based foam filters:

- It aids in gas elimination during the filtration of inclusions.

- Lightweight design. They are designed for easy handling and installation.

- Versatile in usability. Easily compatible with materials beyond aluminum.

- The filters are effective at reducing even small nuclei. They significantly lower the solidification time.

- Durable. Flexible. Resistant to high temperature and pressure.

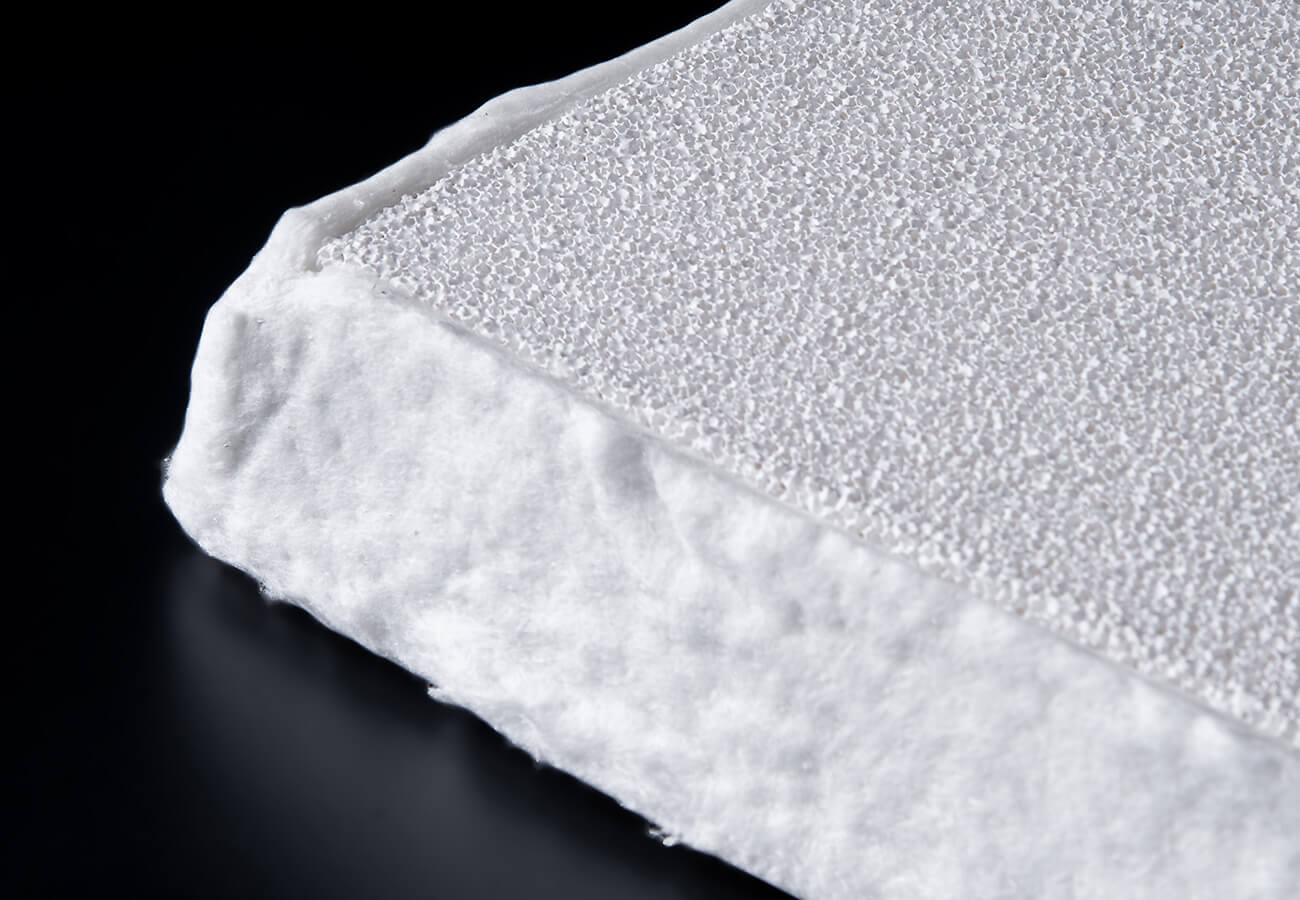

- Sealing gaskets are available in various materials, such as fiber cotton, expandable cotton, and fiber paper.

Features

Here at SEFU, we pack numerous advantages into our products, prioritizing efficiency, performance, and quality yield. Here’s what you can expect:

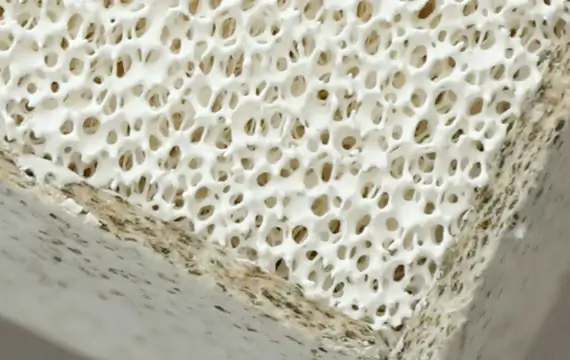

- Highly porous design increases the surface area for molten metal interaction.

- Resilient to erosion. Effectively handling high turbulence rates.

- The filter remains stable at high temperatures without oxidizing.

- Snug filter fit reduces bypassing through gaps.

Applications

Alumina plates are widely used in various applications, such as foils and profiles, primarily for use in alloys and other non-ferrous metals.

- Automotive: Engine blocks, cylinder heads, pistons, and transmission housings

- Aerospace: Turbine blades, wing spares, fuselage parts, and landing gear components

- Construction: Beams, frames, and braces

- Containers: Aluminum cans and foils

Why Choose SEFU for Plate-Shaped Alumina Filters?

Precision castings in the automotive and aeronautical industries, where the inclusion rate needs to be kept at absolute zero, even a few microns of inclusions can significantly impact the casting and surface quality of alloys. SEFU has spent over a decade perfecting a solution that enables the production of lightweight, defect-free, high-strength aluminum casting materials. We focus on advanced research to enhance aluminum filtration processes. This helps us create casting aluminum filters that are stronger, more durable, and resistant to corrosion.

At SEFU, we go the extra mile for casting houses by focusing on:

- More open structure: Designed to ensure easy flow of fluids at high pressure

- Reduced preheating time: Allows less temperature difference both above and below the filter

- Gasket materials: Options like fiber cotton, expandable cotton, and fiber paper

- Falling surface slag rate is less: Sourcing high-purity raw alumina powder. Contamination-free

Related Products

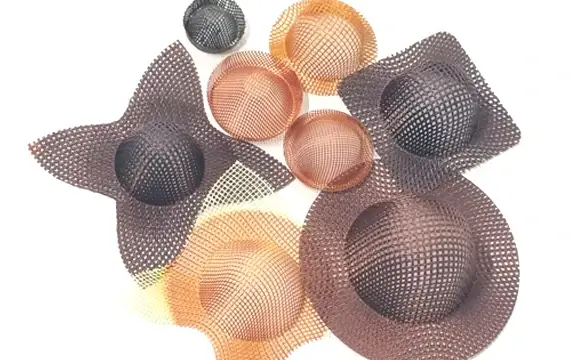

Available in a wide range of refractory ceramic casting materials for your casting production.

Invest in the quality and efficiency of your aluminium casting process with our ceramic filters. Enjoy efficient purification, superior surface quality, enhanced casting integrity, and increased productivity. Choose SF-Foundry as your trusted partner for ceramic filters for aluminium casting. Contact us today to get started.

Experience the benefits of our ceramic filters for aluminium casting. Schedule a consultation with our experts today to discuss your specific challenges and find the ideal solution for your casting process.

- Contact us at +86 13785803358

- Email us at info@sf-foundry.com

Al₂O₃-based filters can easily go for non-ferrous metal casting applications. These filters are primarily designed for molten aluminum and its alloy filtration. Due to their stability at high temperatures and resistance to chemical reactions, they can also be used with copper-based alloys, as well as magnesium and zinc.

Aluminum oxide is non-toxic. It has no negative effects on the environment or personnel around it. Although we recommend following local regulations in the disposal of the filters, since they can barely be reused, disposal is a mere practice.

In many ways, it can be a great add-on;

- Sealing gaskets create a tight fit between the filter and the holder, eliminating any leaks around the filter.

- During pouring, dislodging may occur. These gaskets stabilize the filter, providing good mechanical strength.

- No bypass of the metal through gaps.

- Inclusion-free cast metal.

SEFU offers a variety of foam filters for different needs. We are well-equipped with a range of dimensions and specifications. Our highly specialized R&D allows for easy configuration of what’s best for your needs.

Clean the gating system and ensure there is no debris, dust, or contaminants. Calibrate the right size filter and insert it into the gating system right before the mold cavity, most likely in the forefront of the molten metal flow. During the pouring, check if there is any clogging in the line. If so, ensure that your filters aren’t damaged or worn.