Introduction

Italy has long been renowned for its rich tradition in ceramics and porcelain production. The country’s ceramics industry is known for its quality craftsmanship and innovative techniques. One crucial component of ceramic production is ceramic foam filters, which play a pivotal role in ensuring the quality of the final products.

Ceramic Foam Filters: A Crucial Component

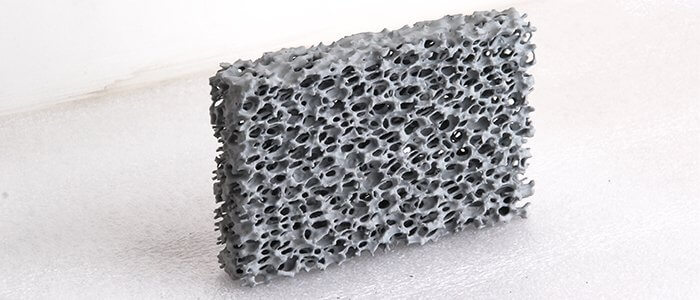

Ceramic foam filters are porous structures made from various ceramic materials, such as silicon carbide or alumina. They are an integral part of the ceramic casting process. These filters are used to remove impurities, such as oxides, slag, and non-metallic inclusions, from molten metal before it is cast into ceramic molds. As a result, they contribute significantly to improving the quality and integrity of final ceramic products.

Annual Import Output

In terms of trade usage, Italian companies involved in metal casting often import ceramic foam filters from other countries as well. This allows them access to a broader range of options and ensures a steady supply of high-quality filters for their production processes.

Furthermore, Italian companies also export ceramic foam filters to other countries around the world. Their expertise and experience make them competitive players in the global market.

Overall, the sale situation of ceramic foam filters is robust in Italy due to increased demand from the metal casting industry. The trade usage involves both imports and exports by Italian companies who recognize its importance for achieving high-quality castings.

Ceramic foam filters are widely used in various industries, including the metal casting industry. In Italy, the sale situation and trade usage of ceramic foam filters have been significant.

The demand for ceramic foam filters in Italy has been steadily increasing over the years. This can be attributed to the growth of the metal casting industry in the country. Ceramic foam filters play a crucial role in this industry as they help remove impurities from molten metals, resulting in higher-quality castings.

To gain a comprehensive understanding of Italy’s ceramic foam filter import market, it is essential to consider the annual import output. Unfortunately, specific data on annual import quantities are not readily available, as this market is relatively niche and specialized. Importers of ceramic foam filters in Italy are often small to medium-sized enterprises that do not publicly disclose detailed import data.

Major Importing Countries

Italy’s ceramic foam filter imports primarily come from a select group of countries that specialize in the production of these critical components. The following are some of the major importing countries:

China: China is a significant source of ceramic foam filters for Italy. Chinese manufacturers offer a wide range of products, and their competitive pricing makes them an attractive option for Italian importers.

Germany: German ceramic foam filter manufacturers are known for their high-quality products and precision engineering. Italy imports a notable quantity of ceramic foam filters from Germany to meet its quality standards.

United States: U.S.-based manufacturers also supply ceramic foam filters to the Italian market. These filters often cater to specialized applications where precise control over impurities is required.

Market Trends and Dynamics

Several factors influence the dynamics of Italy’s ceramic foam filter import market:

Quality and Certification: Italian importers prioritize the quality and certification of ceramic foam filters. Filters that meet international quality standards, such as ISO 9001, are highly sought after.

Customization: Customized ceramic foam filters that cater to specific casting requirements are in demand. Italian manufacturers often work closely with suppliers to develop tailored solutions.

Environmental Concerns: Sustainability and eco-friendly materials are gaining importance in the ceramic foam filter market. Importers are increasingly looking for filters made from recyclable or biodegradable materials.

Competitive Pricing: Price competitiveness remains a significant factor in supplier selection. Importers explore various options to ensure cost-effectiveness without compromising on quality.

Challenges and Future Prospects

Despite the growing demand for ceramic foam filters in Italy, the market faces some challenges:

Supply Chain Disruptions: Global disruptions, such as the COVID-19 pandemic, can disrupt the supply chain and affect the availability of ceramic foam filters.

Regulatory Compliance: Meeting evolving environmental and safety regulations is essential for importers and manufacturers alike.

Technological Advancements: Keeping up with advancements in filter technology is crucial to maintaining product quality and competitiveness.

In conclusion, Italy’s import market for ceramic foam filters is closely tied to the country’s ceramics industry, which has a long history of producing high-quality products. While specific import data may be limited, the market is characterized by a focus on quality, customization, and competitive pricing. As Italy continues to innovate in the ceramics sector, the demand for ceramic foam filters is expected to remain steady, presenting opportunities and challenges for importers and manufacturers alike.