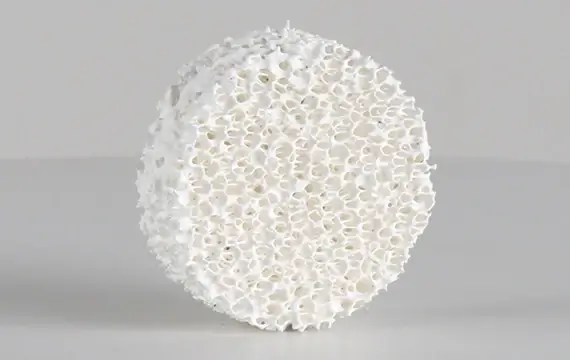

Alumina Foam Filters: Enhancing Metal Casting Excellence

At SF-Foundry, we specialize in crafting top-of-the-line alumina foam filters tailored to the exacting demands of metal casting processes. With a commitment to excellence and innovation, our alumina foam filters are engineered to deliver superior performance, ensuring impeccable casting quality and enhanced productivity for our clients.

Why Choose Our Alumina Foam Filters?

- Unmatched Quality: Crafted from high-purity alumina materials, our foam filters exhibit exceptional durability, thermal stability, and resistance to molten metals, ensuring reliable performance even in the most demanding casting environments.

- Enhanced Productivity: By optimizing metal flow and reducing turbulence during the casting process, our alumina foam filters help minimize casting defects, improve yield rates, and streamline production, ultimately enhancing productivity and reducing overall costs.

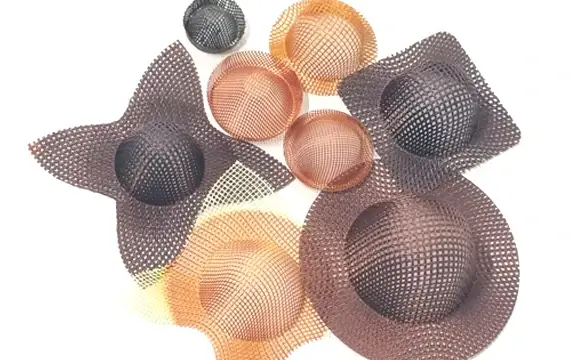

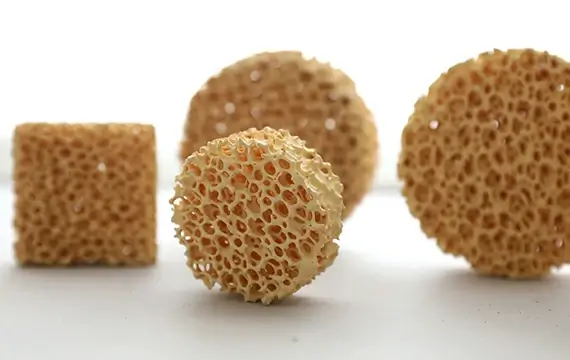

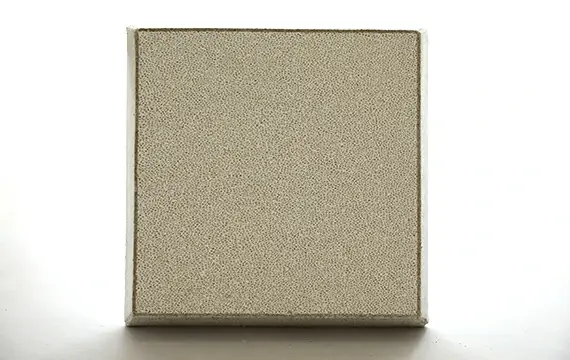

- Customizable Solutions: We understand that every casting application is unique. That’s why we offer customizable alumina foam filters in various shapes, sizes, and PPI configurations to suit your specific requirements, whether you’re casting aluminum alloys, copper, bronze, or other metals.

- Expert Support: Our team of experienced engineers and technical experts is dedicated to providing personalized support and guidance every step of the way, from initial design consultation to post-installation assistance, ensuring optimal performance and satisfaction.

- Product Parameters

| Chemical Composition | Al2O3, SiO2 |

| Porosity (%) | 80-90% |

| Application Temperature | Max.1100°C |

| Compression Strength (Mpa) | ≥0.8 |

| Thermal Shock Resistance | 1100°C-room temperature 6 times |

| Bulk Density | 0.35-0.45g/cm3 |

Wide Casting Applications

Our alumina foam filters are suitable for various casting processes, ensuring versatility across different industries and applications, including:

- Pressure Casting

- Sand Casting

- Permanent Mold Casting

- Precision Casting

- Investment Casting

High-Temperature Resistance

Engineered to withstand extreme temperatures, our alumina foam filters can operate effectively at temperatures up to 1100°C, making them ideal for use in high-temperature casting processes without compromising performance.

Precise Pore Size Control

With pore sizes ranging from 10 to 60 PPI (pores per inch), our filters offer precise filtration tailored to your specific casting needs, effectively removing impurities, oxides, and inclusions from molten metal to produce flawless castings with minimal defects.

Related Products

Other refractory ceramic casting materials are available for use in your casting production.

Contact Us Today

Elevate your metal casting processes with our premium alumina foam filters. Contact us today to learn more about our products, discuss your specific casting requirements, and discover how we can help you achieve casting excellence.