Introduction:

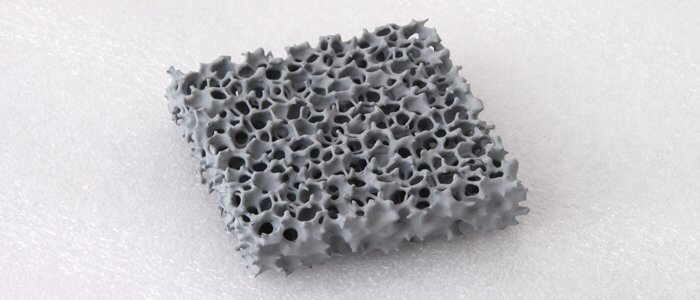

Sic foam, also known as silicon carbide foam, is a remarkable material that has gained significant attention in recent years due to its exceptional properties and applications in various industries. Silicon carbide (SiC) foam is a lightweight, porous, and high-strength material with excellent thermal, mechanical, and chemical stability.

Birth of Sic Foam:

The production of Sic foam involves a combination of raw materials and advanced manufacturing techniques. Generally, there are two main approaches to creating Sic foam:

a. Replication Method:

The replication method starts with a polymeric foam template, which is impregnated with a slurry containing silicon carbide particles. The slurry is often prepared by mixing SiC powder with a binder and dispersing agent. Afterward, the template is heated in an inert atmosphere to a high temperature, causing the binder to burn off and the SiC particles to sinter, forming a solid Sic structure with a similar porous network to the original template.

b. Polymer Pyrolysis:

The polymer pyrolysis method involves mixing a silicon carbide powder with a polymer foam precursor. This mixture is then heated under controlled conditions, leading to the decomposition of the polymer and the formation of silicon carbide, resulting in a porous Sic foam structure.

Feasibility of Sic Foam:

a. Thermal Stability:

Sic foam exhibits outstanding thermal stability, making it suitable for high-temperature applications. Experimental data from thermal conductivity tests have shown that Sic foam displays excellent performance at temperatures exceeding 1000°C, outperforming many conventional materials.

b. Mechanical Properties:

The mechanical strength of Sic foam is a key factor contributing to its feasibility. Tensile strength, compressive strength, and flexural strength tests have demonstrated that Sic foam possesses remarkable mechanical properties, ensuring its structural integrity even under demanding conditions.

c. Chemical Resistance:

Sic foam has a high level of resistance to chemicals and corrosive environments. Immersion tests in various acids, bases, and solvents have revealed minimal weight changes and surface degradation, further confirming the feasibility of Sic foam in chemically harsh applications.

Effectiveness of Sic Foam:

a. Lightweight and High Porosity:

The exceptional porosity of Sic foam, with a typical range of 80-90%, results in a lightweight material. This property is highly advantageous in aerospace, automotive, and other industries, where weight reduction is critical to improve fuel efficiency and performance.

b. Thermal Insulation:

Due to its low thermal conductivity, Sic foam serves as an effective thermal insulator. This property is extensively used in thermal management systems, furnaces, and kilns, where maintaining temperature gradients is vital.

c. Filtration and Catalysis:

The high surface area and open-cell structure of Sic foam make it an excellent candidate for filtration and catalysis applications. Experimental data have shown remarkable performance in removing particulates and promoting catalytic reactions.

Conclusion:

Silicon carbide foam (Sic foam) is a remarkable material that exhibits outstanding properties, making it an ideal candidate for various industrial applications. Its creation methods, thermal stability, mechanical properties, and chemical resistance have been extensively studied through experimental data.

The feasibility of Sic foam is evident from its lightweight nature, high porosity, thermal insulation capabilities, and potential applications in filtration and catalysis. As research and development continue, Sic foam holds the promise of further enhancing industries and technologies, proving itself as a versatile and effective material for the future.